Table of Contents

Eccentric turning on CNC is a process that allows you to create complex shapes with precision and accuracy. This technique involves offsetting the center of rotation from the center of the workpiece, resulting in a unique and intricate design.

To achieve eccentric turning on CNC, you must have a solid understanding of the CNC machine’s capabilities and settings. With this knowledge, you can create stunning and intricate designs that will leave a lasting impression. In this guide, we will walk you through the steps to master eccentric turning on CNC and create impressive designs that will elevate your work to the next level.

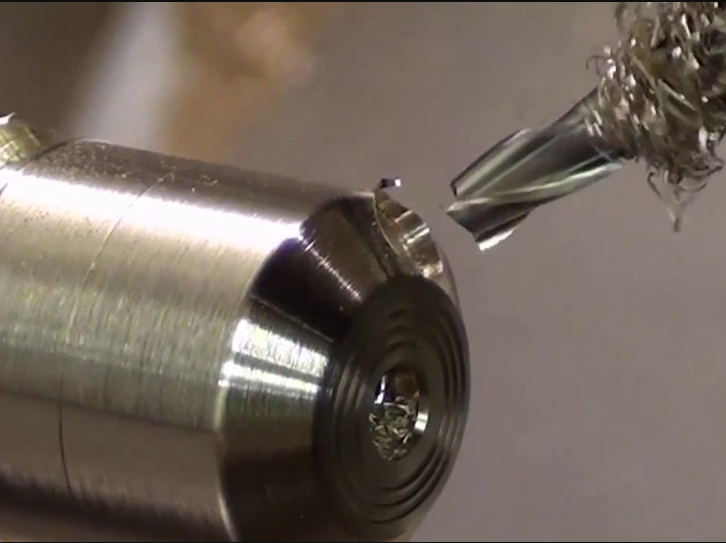

Eccentric turning on CNC involves turning a workpiece off-center, which is useful for creating non-circular shapes or for machining off-center holes. To do this, first, mount the workpiece off-center and then set the CNC machine to move the tool in a circular path around the off-center point. Use the CNC software to adjust the tool’s position and the cutting depth to achieve the desired shape. Remember to double-check your setup and make any necessary adjustments before starting the machining process.

How to Do Eccentric Turning on CNC?

Eccentric turning is a process used in CNC machining to create non-circular shapes. It involves rotating the workpiece off-center and cutting it to achieve the desired shape. This technique is commonly used in the automotive and aerospace industries, where precision is essential. In this article, we will discuss how to do eccentric turning on CNC machines.

What is Eccentric Turning?

Eccentric turning is a type of machining process that allows for the creation of non-circular shapes. It involves rotating the workpiece off-center and cutting it to achieve the desired shape. The term “eccentric” refers to the fact that the center of rotation is not the same as the center of the workpiece.

To perform eccentric turning on a CNC machine, you need to use a special chuck that allows you to mount the workpiece off-center. The chuck is designed to hold the workpiece at an angle, which allows you to rotate it around a different center point.

Benefits of Eccentric Turning

There are several benefits to using eccentric turning in CNC machining. One of the main advantages is that it allows you to create non-circular shapes with a high degree of precision. This is particularly useful in the automotive and aerospace industries, where complex shapes are often required.

Another benefit of eccentric turning is that it can be used to create parts with a reduced weight. By removing material from specific areas of the workpiece, you can create a part that is lighter without sacrificing strength.

How to Perform Eccentric Turning on CNC Machines

To perform eccentric turning on a CNC machine, you need to follow these steps:

1. Mount the workpiece on the chuck: The workpiece should be mounted off-center using a special chuck designed for eccentric turning.

2. Set the center point: Once the workpiece is mounted, you need to set the center point for the rotation. This is done by using a tool to measure the distance between the center of the workpiece and the center of rotation.

3. Program the CNC machine: You need to program the CNC machine to move the cutting tool along the desired path. This will depend on the shape you want to create and the specific characteristics of your workpiece.

4. Start the cutting process: Once the machine is programmed, you can start the cutting process. The machine will move the cutting tool along the programmed path, cutting away material to create the desired shape.

5. Check the results: After the cutting process is complete, you should check the results to ensure that the part is within the required tolerances.

Eccentric Turning vs. Traditional Turning

Traditional turning involves rotating the workpiece around its center point and cutting material to create a circular shape. Eccentric turning, on the other hand, involves rotating the workpiece off-center and cutting material to create a non-circular shape.

The main benefit of eccentric turning over traditional turning is that it allows you to create non-circular shapes with a high degree of precision. This is particularly useful in industries where complex shapes are required.

Eccentric Turning Applications

Eccentric turning is commonly used in the automotive and aerospace industries to create complex parts with high precision. It is also used in the medical industry to create implants and other medical devices.

Another application of eccentric turning is in the creation of gears. Eccentric turning can be used to create non-circular gears that have specific shapes and tooth profiles.

Eccentric Turning Challenges

One of the main challenges of eccentric turning is ensuring that the workpiece is mounted correctly. If the workpiece is not mounted at the correct angle, the resulting part may be out of tolerance.

Another challenge of eccentric turning is programming the CNC machine to follow the correct path. This requires a high degree of precision and expertise in CNC programming.

Conclusion

Eccentric turning is a machining process that allows you to create non-circular shapes with a high degree of precision. It is commonly used in the automotive and aerospace industries to create complex parts with specific shapes and tolerances. By following the steps outlined in this article, you can perform eccentric turning on a CNC machine and achieve the desired results.

Frequently Asked Questions

Here are some frequently asked questions about how to do eccentric turning on CNC:

What is eccentric turning?

Eccentric turning is a machining process that involves turning a workpiece off-center, rather than on-center. This creates an eccentric shape that is different from a regular circular shape. Eccentric turning is often used to create camshafts, crankshafts, and other parts that require an off-center shape.

To perform eccentric turning on a CNC machine, you will need to use special software that can create the necessary tool paths. You will also need to have a chuck or other fixture that can hold the workpiece off-center. Once you have set up the machine and created the tool paths, you can begin the machining process.

What are the benefits of eccentric turning?

Eccentric turning offers several benefits compared to regular turning. For example, it can help to reduce vibration and noise in rotating parts such as camshafts and crankshafts. This can improve the overall performance and lifespan of the part. Eccentric turning can also be used to create unique shapes and designs that may be difficult or impossible to achieve with regular turning.

Additionally, eccentric turning can be used to create parts with varying thicknesses or wall thicknesses. This can be particularly useful in applications where weight or balance is important, such as in aerospace or automotive industries.

What materials can be used for eccentric turning?

Eccentric turning can be used with a wide range of materials, including metals, plastics, and composites. The specific material used will depend on the application and the required properties of the finished part. For example, some materials may be more suitable for high-temperature or high-stress applications, while others may be better suited for low-weight or corrosion-resistant applications.

When selecting a material for eccentric turning, it is important to consider factors such as strength, durability, machinability, and cost. You should also consider any special requirements or regulations for the application, such as safety or environmental regulations.

What are the challenges of eccentric turning?

Eccentric turning can present several challenges compared to regular turning. For example, it can be more difficult to hold the workpiece securely in place, especially if the off-center shape is significant. This can lead to vibration, chatter, or other machining problems that can affect the quality of the finished part.

In addition, eccentric turning may require specialized tooling or cutting strategies that can be more complex or expensive than regular turning. This can add to the overall cost and time required for the machining process.

How can I improve my eccentric turning skills?

To improve your eccentric turning skills, it is important to start with a solid understanding of basic turning principles and techniques. You should also familiarize yourself with the specific software, tooling, and machines used for eccentric turning.

One effective way to improve your skills is to practice on small or simple parts before moving on to more complex shapes or designs. You can also seek out training or mentorship from experienced machinists or industry experts, or participate in online forums or communities where you can ask questions and share tips and advice with other professionals.

In conclusion, Eccentric Turning on CNC is a technique that can produce unique and complex shapes with precision and accuracy. While it may seem daunting at first, with the proper tools and techniques, anyone can master this skill.

Firstly, it is essential to have a solid understanding of the fundamentals of CNC machining. This includes knowing how to set up and program your machine, as well as understanding the properties of different materials.

Secondly, practice makes perfect. Before attempting to create complex shapes, it’s important to start with simple designs and gradually work your way up. This will help you gain confidence and familiarity with the process.

Lastly, don’t be afraid to experiment and push the boundaries of what’s possible with eccentric turning. With some creativity and ingenuity, you can create truly unique and impressive pieces that will set you apart from the competition.

Overall, Eccentric Turning on CNC is an exciting and challenging technique that can produce stunning results. By following these tips and putting in the necessary time and effort, you can master this skill and unlock a world of possibilities in the world of machining.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com