Table of Contents

- How to Find Center on CNC Lathe?

- Step 1: Preparations

- Step 2: Locate the Live Center

- Step 3: Set the Machine to Zero

- Step 4: Measure the Distance

- Step 5: Half the Distance

- Step 6: Input the Offset Value

- Step 7: Test the Position

- Step 8: Start the Machining Process

- Step 9: Benefits of Accurately Finding the Center on CNC Lathe

- Step 10: Center Finding vs. Center Drilling

- Frequently Asked Questions

Are you struggling to find the center on your CNC lathe? Don’t worry, you are not alone. Many lathe operators find it challenging to locate the center accurately. However, finding the center is a crucial step in achieving precise cuts and achieving the desired outcome. In this article, we will guide you through the process of finding the center on your CNC lathe, so you can produce accurate and high-quality results every time. So, let’s get started!

- Set the workpiece on the chuck and tighten it.

- Mount the dial indicator on the tool post and touch it to the workpiece.

- Rotate the chuck and note the maximum and minimum readings on the dial.

- Adjust the position of the workpiece until the dial reads the same value on both sides.

- Repeat the process for the other axis to find the center.

How to Find Center on CNC Lathe?

CNC (Computer Numerical Control) lathe machines are an essential tool in the manufacturing industry. They are capable of producing precise and complex shapes effortlessly. However, to achieve the desired results, it is crucial to find the center of the workpiece accurately. In this article, we will discuss the steps to find the center on a CNC lathe machine.

Step 1: Preparations

Before starting the process, it is essential to prepare the workpiece and the machine. Ensure that the workpiece is properly secured in the chuck and that the chuck jaws are clean from debris. Also, make sure that the machine is correctly set up, and the center height is adjusted according to the workpiece.

Once the workpiece and machine are ready, clean the surface of the workpiece where the center will be located. Use a center drill to create a small dimple at the center point. This will help the live center to grip the workpiece firmly.

Step 2: Locate the Live Center

The next step is to locate the live center. The live center is a vital component of the CNC lathe machine that rotates with the workpiece. It helps to support the workpiece and ensures that it is accurately centered. To locate the live center, move the tool turret to the tailstock end of the machine.

Insert the live center into the tailstock and tighten it securely. The live center should be perfectly aligned with the center of the workpiece.

Step 3: Set the Machine to Zero

Once the live center is in place, set the machine to zero. This means that the machine’s position is aligned with the center of the workpiece. To set the machine to zero, move the tool turret to the starting position.

Then, using the jog handle or the jog buttons, move the tool turret towards the workpiece until it touches the center drill dimple. Once the tool turret touches the workpiece, set the machine to zero.

Step 4: Measure the Distance

After setting the machine to zero, measure the distance between the live center and the tool turret. To measure the distance accurately, use a dial indicator. Place the dial indicator on the tool turret and move it towards the live center.

As the dial indicator moves, it will show the distance between the live center and the tool turret. Record this distance as it will be used to find the center of the workpiece.

Step 5: Half the Distance

To find the center of the workpiece, you need to half the distance that you measured in step 4. Use a calculator or a measuring tool to calculate half the distance accurately. This will give you the offset value that you need to input into the CNC lathe machine.

Step 6: Input the Offset Value

Once you have calculated the offset value, input it into the CNC lathe machine. This will tell the machine to position the tool turret accurately and find the center of the workpiece. Input the offset value into the machine’s control panel or software.

Step 7: Test the Position

After inputting the offset value, test the position of the tool turret. Move the tool turret towards the workpiece and check if it is accurately centered. To check the position, use a dial indicator and measure the distance between the tool turret and the live center.

If the distance is the same as the offset value, then the tool turret is accurately centered. If not, adjust the offset value and repeat the process until the tool turret is perfectly centered.

Step 8: Start the Machining Process

Once the tool turret is accurately centered, you can start the machining process. Use the CNC lathe machine to create the desired shape or cut on the workpiece. The machine will automatically adjust the tool turret position to ensure that the workpiece is precisely machined.

Step 9: Benefits of Accurately Finding the Center on CNC Lathe

Accurately finding the center on a CNC lathe machine has several benefits. Firstly, it ensures that the workpiece is precisely machined, resulting in high-quality products. Secondly, it reduces the risk of tool breakage, as the tool is accurately positioned. Lastly, it saves time and money by reducing the need for rework or scrapping of the workpiece.

Step 10: Center Finding vs. Center Drilling

Center finding and center drilling are two techniques used to find the center of a workpiece on a CNC lathe machine. Center finding is a more accurate and reliable technique as it uses a live center and a dial indicator to locate the center of the workpiece. Center drilling, on the other hand, creates a small dimple in the center of the workpiece, which can be less precise and accurate.

In conclusion, accurately finding the center on a CNC lathe machine is essential for producing high-quality products. By following the steps outlined in this article, you can ensure that your workpiece is accurately positioned, resulting in precise machining and reduced tool breakage.

Frequently Asked Questions

Here are some common questions and answers about how to find the center on a CNC lathe.

What is a CNC Lathe?

A CNC lathe is a machine tool used for shaping a piece of material, such as wood or metal, by rotating it rapidly along its axis while pressing a cutting tool against it. CNC stands for “computer numerical control,” meaning that the machine is controlled by a computer program. CNC lathes are used in a variety of industries, including manufacturing, automotive, and aerospace.

To use a CNC lathe, the operator must first program the machine with the desired cutting path and other parameters, such as cutting speed and depth. The operator then loads the material into the lathe and starts the machine, which automatically follows the programmed instructions to shape the material.

Why is it Important to Find Center on a CNC Lathe?

Finding the center on a CNC lathe is important because it ensures that the material being shaped is perfectly aligned with the cutting tool. If the material is off-center, the cutting tool may not remove material evenly, leading to an uneven surface or other defects. This can be especially problematic when working with high-precision parts, such as those used in aerospace or medical devices.

In addition, finding the center on a CNC lathe can help reduce the amount of material waste and increase the efficiency of the machining process. By ensuring that the cutting tool is always in the correct position, the operator can minimize the amount of material that needs to be removed and reduce the overall machining time.

How Do You Find Center on a CNC Lathe?

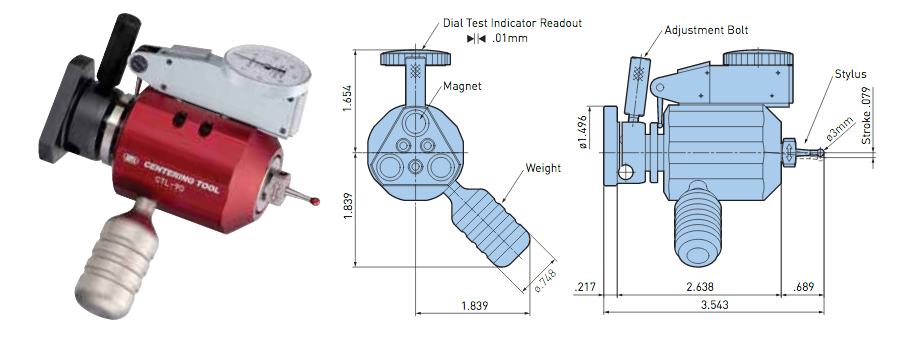

There are several methods for finding center on a CNC lathe, depending on the type of material being machined and other factors. One common method involves using a center finder tool, which is a small device that helps locate the center of a piece of material. The center finder is inserted into the lathe chuck and positioned against the material, and then the chuck is tightened to hold the material in place.

Another method for finding center on a CNC lathe involves using a dial indicator, which is a tool that measures small distances and movements. The dial indicator is attached to the cutting tool or the lathe carriage, and then the machine is slowly rotated while the operator watches the dial indicator to determine when the cutting tool is centered on the material.

What Are Some Tips for Finding Center on a CNC Lathe?

When using a center finder tool to locate the center on a CNC lathe, it’s important to make sure that the tool is properly aligned with the material. This can be done by using a square or other measuring tool to ensure that the center finder is perpendicular to the material.

Another tip for finding center on a CNC lathe is to start with a small amount of material and gradually increase the cutting depth. This can help prevent the cutting tool from breaking or becoming damaged, and can also help ensure that the material is being shaped evenly.

What Are Some Common Mistakes When Finding Center on a CNC Lathe?

One common mistake when finding center on a CNC lathe is not taking into account the diameter of the cutting tool. This can lead to errors in the machining process, as the tool may not be centered on the material even if the machine is properly calibrated.

Another mistake when finding center on a CNC lathe is not properly securing the material in the lathe chuck. If the material is not firmly held in place, it may shift or move during the machining process, leading to errors or defects in the final product.

In conclusion, finding center on a CNC lathe is an essential skill that every operator needs to know. It is vital to ensure that the machine works effectively and produces high-quality parts. By following the simple steps outlined above, you can locate the center accurately and quickly.

Remember to take your time and use the appropriate tools when finding center. Rushing the process could result in inaccuracies and errors that could affect the final product’s quality. Additionally, always double-check your measurements and make adjustments as necessary.

In summary, knowing how to find center on a CNC lathe is a valuable skill that every operator should possess. With practice and patience, you can become proficient in this task and produce high-quality parts that meet or exceed your customers’ expectations.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com