Table of Contents

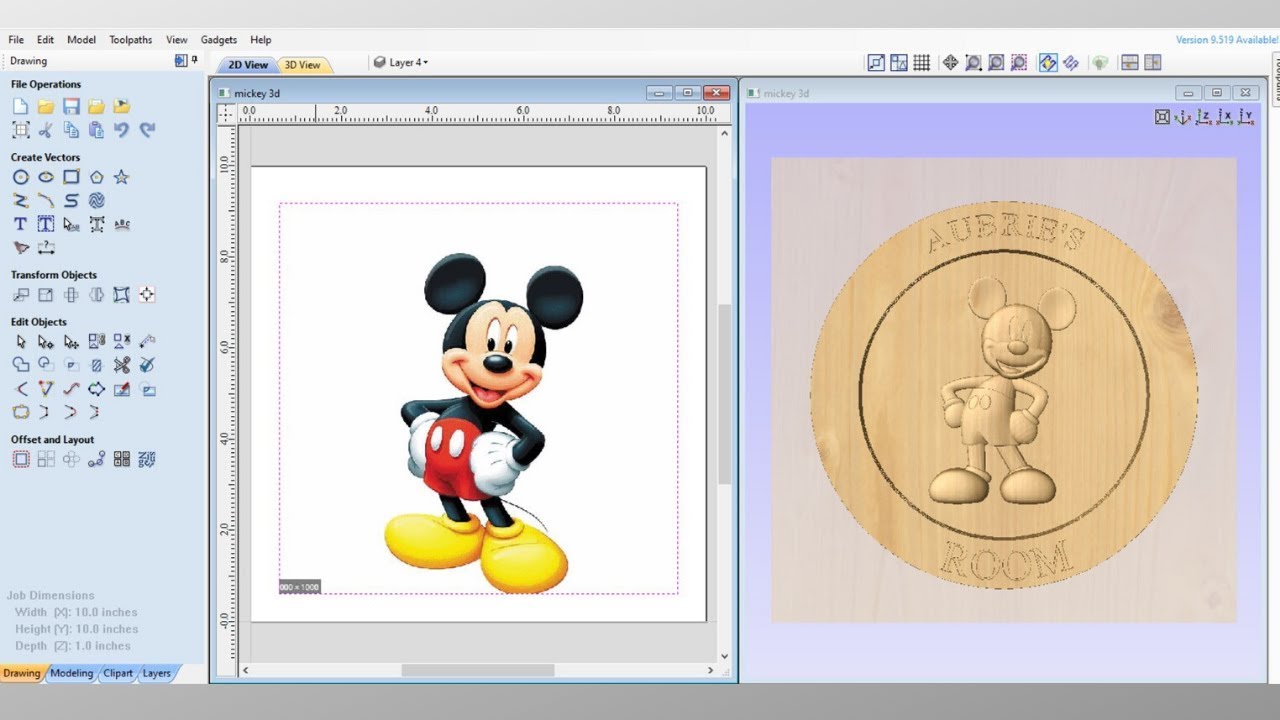

Do you want to learn how to make 3D models for CNC routers? Are you interested in creating intricate designs and patterns that can be carved into wood, metal, or plastic? Look no further than this comprehensive guide that will teach you everything you need to know.

With step-by-step instructions and helpful tips, you’ll be able to create stunning 3D models that will impress even the most experienced CNC router users. Whether you’re a beginner or an experienced designer, this guide will provide you with the skills and knowledge to take your designs to the next level. So, grab your computer and let’s get started on this exciting journey into the world of 3D modeling for CNC routers.

- Choose a 3D modeling software such as SketchUp, Fusion 360, or Blender.

- Create your 3D design or download a pre-made one from a website.

- Save your design in a file format that is compatible with your CNC router software.

- Import the file into your CNC router software.

- Set up your CNC router machine and choose the appropriate cutting tools.

- Send your design to the CNC router and watch it come to life.

How to Make 3D Models for CNC Router

Are you interested in creating 3D models for CNC router? CNC routers are used to cut and shape materials such as wood, plastic, and metal. Creating 3D models for CNC router can be a challenging task, but with the right tools, skills, and knowledge, it can be a rewarding experience. In this article, we will guide you through the process of making 3D models for CNC router.

Step 1: Choose the Right Design Software

The first step in creating 3D models for CNC router is to choose the right design software. There are many software options available, both free and paid. Some of the popular software options include:

- SketchUp

- Fusion 360

- AutoCAD

- SolidWorks

Each software has its own unique features and benefits. It is important to choose a software that suits your needs and skill level.

Once you have chosen your design software, it is important to learn how to use it effectively. Many software options have tutorials and online courses available to help you learn.

Step 2: Create Your Design

After choosing your design software, it is time to create your design. This can be done by sketching your design on paper, using reference images, or creating a digital sketch.

Once you have your design, you will need to create a 3D model. This can be done using your design software by creating a series of shapes and manipulating them to create your desired design.

Step 3: Export Your Design

Once you have created your 3D model, you will need to export it in the correct format for CNC router. The most common file formats for CNC router include:

- .STL

- .OBJ

- .DXF

It is important to check with your CNC router manufacturer to determine the correct file format for your specific machine.

Step 4: Prepare Your CNC Router

Before you can begin cutting your design, you will need to prepare your CNC router. This includes selecting the correct cutting tool, setting the correct cutting depth, and securing your material in place.

It is important to follow the manufacturer’s instructions for your specific CNC router to ensure safe and accurate cutting.

Step 5: Cut Your Design

Once your CNC router is prepared, it is time to cut your design. This can be done by loading your design file into your CNC router software and following the cutting instructions.

It is important to monitor the cutting process to ensure that the cutting tool is working properly and that your material is being cut accurately.

Step 6: Clean and Finish Your Design

After cutting your design, it is important to remove any excess material and clean your design. This can be done using sandpaper, a file, or other finishing tools.

Once your design is clean, you can apply a finish such as paint, stain, or varnish to enhance its appearance.

Benefits of Making 3D Models for CNC Router

- Ability to create complex designs with precision

- Efficient use of materials

- Reduced production time

- Increased customization options

3D Models for CNC Router vs. Traditional Methods

- 3D models allow for greater precision and accuracy

- 3D models can be created more efficiently than traditional methods

- 3D models offer greater customization options

- Traditional methods may be more suitable for small-scale projects

In conclusion, creating 3D models for CNC router can be a challenging yet rewarding experience. By following these steps and utilizing the right tools and software, you can create complex and precise designs that can be used for a variety of projects.

Frequently Asked Questions

In this section, you will find answers to some of the most commonly asked questions about making 3D models for CNC routers.

What software can I use to create 3D models for CNC routers?

There are several software programs available that can be used to create 3D models for CNC routers. Some of the most popular ones include Autodesk Fusion 360, SketchUp, Rhino, and SolidWorks.

When choosing a software program, it’s important to consider your skill level, budget, and the complexity of the models you want to create. Many of these programs offer free trials, so you can test them out before making a purchase.

What file formats are compatible with CNC routers?

The most commonly used file format for CNC routers is G-code. This is a programming language that is used to control the movement and operation of the machine.

However, many software programs allow you to export your 3D models in a variety of file formats, including STL, OBJ, and DXF. It’s important to check the specifications of your CNC router to ensure that it is compatible with the file format you choose.

How can I ensure that my 3D models are suitable for CNC routing?

When creating 3D models for CNC routers, it’s important to keep in mind the limitations of the machine. CNC routers can only cut in a straight line, so it’s important to avoid complex curves and angles that may be difficult to cut.

Additionally, it’s important to ensure that your model is properly scaled and has enough thickness to withstand the cutting process. You should also check for any intersecting or overlapping surfaces that may cause errors in the cutting process.

What materials can be used with CNC routers?

CNC routers can be used with a variety of materials, including wood, plastic, and metal. The type of material you choose will depend on the application and the complexity of the model you want to create.

It’s important to consider the properties of the material, such as its hardness and density, when designing your model. You should also consider the cutting speed and feed rate that will be used with the material to ensure a clean and accurate cut.

What are some tips for optimizing my 3D models for CNC routing?

One of the most important tips for optimizing your 3D models for CNC routing is to simplify the design. This means avoiding complex curves and angles, and using simple shapes and geometries instead.

It’s also important to ensure that your model is properly scaled and has enough thickness to withstand the cutting process. You should also check for any intersecting or overlapping surfaces that may cause errors in the cutting process. Additionally, you can optimize your toolpaths to reduce cutting time and improve the quality of the cut.

In conclusion, making 3D models for a CNC router is a valuable skill to have, whether you’re a hobbyist or a professional. By following these steps, you can create complex and intricate designs that will make your projects stand out. Remember to start with a clear plan, take advantage of available software and tools, and always test your design before sending it to the CNC router.

With the help of modern technology, designing and machining 3D models has never been easier or more accessible. Don’t be afraid to experiment and push your creativity to new heights. The possibilities are endless, and with practice and persistence, you can become a master of 3D modeling for CNC routers.

So, what are you waiting for? Start exploring the exciting world of 3D modeling, and let your imagination run wild. With a bit of practice and patience, you’ll be amazed at what you can accomplish with a CNC router and your own creative vision.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com