Table of Contents

Introduction:

If you are looking for a way to make your extruded aluminum shine like new, then you have come to the right place. Polishing extruded aluminum can be a daunting task, but with the right tools and techniques, you can achieve a mirror-like finish that will leave your aluminum looking better than ever.

Paragraph 1:

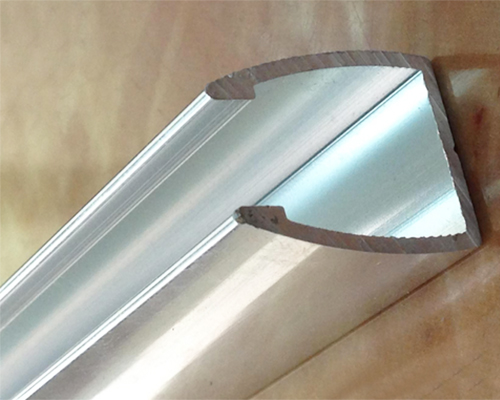

Extruded aluminum is a popular material used in a wide range of applications, from construction to automotive parts. However, over time, aluminum can become dull and tarnished, which can detract from its appearance and reduce its lifespan. Polishing extruded aluminum is a simple and effective way to restore its shine and protect it from further damage.

Paragraph 2:

In this article, we will show you how to polish extruded aluminum using a few simple steps and the right tools. We will cover everything from preparing the surface to selecting the right polish and applying it correctly. So, let’s get started and bring your extruded aluminum back to life!

- Start by cleaning the aluminum with soap and water to remove any dirt or debris.

- Use a fine-grit sandpaper to sand down any rough spots or scratches on the surface.

- Apply a small amount of aluminum polish to a soft cloth and begin rubbing it onto the surface in circular motions.

- Buff the surface with a clean cloth to remove any excess polish and reveal a shiny finish.

How to Polish Extruded Aluminum?

Polishing extruded aluminum can be a daunting task, especially if you don’t know where to start. However, with the right tools and techniques, you can achieve a shiny, polished finish that will make your aluminum surfaces look brand new. In this article, we’ll go over the steps involved in polishing extruded aluminum and provide some tips to help make the process easier.

Step 1: Clean the Surface

Before you begin polishing, it’s important to clean the surface of the aluminum to remove any dirt, grime, or other contaminants. You can use a mild detergent and warm water to clean the surface, or you can use a specialized aluminum cleaner. Be sure to rinse the surface thoroughly with water and dry it completely before moving on to the polishing step.

If you’re dealing with particularly stubborn stains or discoloration, you may need to use a more aggressive cleaner or a polishing compound. These products can help to remove scratches, oxidation, and other types of damage from the surface of the aluminum. Just be sure to follow the manufacturer’s instructions carefully and wear protective gloves and eyewear to avoid getting the product on your skin or in your eyes.

Step 2: Choose the Right Polishing Method

There are several different methods you can use to polish extruded aluminum, including hand polishing, machine polishing, and buffing. Each method has its own advantages and disadvantages, so it’s important to choose the one that’s best suited to your needs and preferences.

Hand polishing is the most basic method of polishing aluminum and involves using a soft cloth or polishing pad to apply a polishing compound to the surface of the aluminum. This method is best suited for smaller surfaces or areas that are difficult to reach with a machine.

Machine polishing involves using an electric polisher or buffer to apply a polishing compound to the surface of the aluminum. This method is faster and more efficient than hand polishing, but it can be more difficult to control and may require more skill and experience.

Buffing is a more aggressive form of polishing that involves using a buffing wheel or pad to apply a polishing compound to the surface of the aluminum. This method is best suited for heavily scratched or damaged surfaces and can help to remove deep scratches and other types of damage.

Step 3: Apply the Polishing Compound

Once you’ve chosen the right polishing method, it’s time to apply the polishing compound to the surface of the aluminum. Be sure to use a high-quality compound that’s designed specifically for aluminum surfaces, as this will help to ensure the best possible results.

Apply the compound to the surface of the aluminum using a soft cloth or polishing pad, being careful to cover the entire surface evenly. If you’re using a machine or buffer, be sure to follow the manufacturer’s instructions carefully and use the appropriate speed and pressure settings.

Step 4: Polish the Surface

Now it’s time to start polishing the surface of the aluminum. If you’re using a hand polishing method, use a circular motion to apply the compound to the surface of the aluminum, working in small sections at a time. If you’re using a machine or buffer, be sure to keep the pad or wheel moving at all times to avoid creating hot spots or burning the surface of the aluminum.

As you polish, be sure to monitor the progress of the surface and adjust your technique as needed. If you’re using a polishing compound, you may need to add more compound periodically to keep the surface lubricated and prevent the pad or wheel from drying out.

Step 5: Clean the Surface Again

Once you’ve finished polishing the surface of the aluminum, it’s important to clean it again to remove any residual polishing compound or debris. You can use a clean, dry cloth or a specialized aluminum cleaner to clean the surface, being sure to remove all traces of the polishing compound.

Step 6: Apply a Protective Coating

To help maintain the polished finish of your aluminum surfaces, consider applying a protective coating to the surface. There are several different types of coatings available, including wax, sealant, and clear coat.

Wax is a popular choice for protecting aluminum surfaces, as it provides a durable, long-lasting barrier against dirt, grime, and other contaminants. To apply wax, simply use a soft cloth to apply a thin layer of wax to the surface of the aluminum, then buff it off with a clean, dry cloth.

Sealant is another popular choice for protecting aluminum surfaces, as it provides a more durable and long-lasting barrier than wax. To apply sealant, simply follow the manufacturer’s instructions carefully, being sure to apply the sealant evenly and allow it to dry completely before using the surface.

Clear coat is a more permanent protective coating that can be applied to the surface of the aluminum using a spray gun or other specialized equipment. This type of coating provides the most durable and long-lasting protection, but it can be more difficult to apply and requires more skill and experience.

Step 7: Maintain Your Polished Aluminum Surfaces

To keep your polished aluminum surfaces looking their best, it’s important to maintain them regularly. This includes cleaning the surface regularly to remove dirt, grime, and other contaminants, as well as applying a protective coating as needed to help maintain the polished finish.

If you notice any scratches, dents, or other types of damage on the surface of your aluminum, be sure to address them promptly to prevent them from worsening. You can use a polishing compound or other specialized product to remove minor scratches and restore the surface of the aluminum to its original shine.

Conclusion

Polishing extruded aluminum can be a challenging task, but with the right tools and techniques, you can achieve a polished finish that will make your surfaces look brand new. Be sure to choose the right polishing method for your needs, and follow these steps carefully to achieve the best possible results. With regular maintenance and care, your polished aluminum surfaces will continue to shine for years to come.

Frequently Asked Questions

In this section, you will find some common questions and answers on how to polish extruded aluminum. If you have any further questions, feel free to contact us.

How do I prepare the extruded aluminum surface for polishing?

Before polishing the aluminum surface, it is essential to remove any dirt, grease or oil from the surface. You can clean the surface using a degreaser or a mild soap and water solution. Rinse the surface with clean water and dry it with a soft cloth. If there are any scratches on the surface, you can use sandpaper to smooth them out. Begin with a coarser grit sandpaper and progress to a finer grit until the surface is smooth.

After the surface is cleaned and smoothed out, apply a polishing compound using a soft cloth. Rub the compound on the surface in circular motions. Repeat the process until the surface is shiny and smooth. Finally, wipe off the excess compound with a clean cloth.

What is the best way to polish extruded aluminum?

There are different methods to polish extruded aluminum, but the best way is to use a polishing compound. Start by cleaning the surface using a degreaser or a mild soap and water solution. Rinse the surface with clean water and dry it with a soft cloth. After cleaning, apply a small amount of polishing compound to the surface using a soft cloth. Rub the compound on the surface in circular motions. Repeat the process until the surface is shiny and smooth.

If the surface is heavily oxidized, you can use an aluminum brightener to remove the oxidation. After using the brightener, rinse the surface with water and dry it with a soft cloth. Apply the polishing compound to the surface and follow the same process mentioned above.

What type of polishing compound should I use?

There are different types of polishing compounds available in the market, but the best type for extruded aluminum is a high-quality metal polish. Look for a metal polish that is specifically designed for aluminum surfaces. Some popular brands include Mothers, Meguiar’s, and Flitz. Avoid using abrasive or acidic polishes as they can damage the surface.

Before using the polish, make sure to read the instructions carefully. Wear gloves and safety glasses to protect your hands and eyes. Apply the polish in a well-ventilated area and avoid inhaling the fumes.

Can I use a power buffer to polish extruded aluminum?

Yes, you can use a power buffer to polish extruded aluminum, but it is essential to use the correct buffing pad and polishing compound. Use a soft buffing pad and a high-quality metal polish that is specifically designed for aluminum surfaces. Avoid using abrasive or acidic polishes as they can damage the surface.

Before using the power buffer, make sure to read the instructions carefully. Wear gloves and safety glasses to protect your hands and eyes. Use the buffer in a well-ventilated area and avoid inhaling the fumes. Start with a low speed and gradually increase the speed until you achieve the desired shine.

How often should I polish extruded aluminum?

The frequency of polishing extruded aluminum depends on the level of exposure to the elements. If the aluminum is exposed to harsh weather conditions, you may need to polish it more frequently. On average, polishing the aluminum once every six months is sufficient to maintain its shine and protect it from oxidation.

Polishing the aluminum too often can also damage the surface, so it is essential to avoid over-polishing. If the aluminum is not exposed to harsh weather conditions, you can polish it once a year or as needed.

In conclusion, knowing how to polish extruded aluminum is an essential skill for anyone working with this material. By following the steps outlined above, you can achieve a smooth, polished finish that will enhance the appearance and durability of your aluminum products.

Firstly, make sure to clean the aluminum thoroughly before beginning the polishing process. This will remove any dirt or debris that could scratch the surface during polishing. Next, use a polishing compound and a buffing wheel to achieve a high shine. Finally, protect the polished surface with a clear coat or wax to prevent oxidation and maintain the shine.

With these simple steps, you can transform even the dullest piece of extruded aluminum into a polished masterpiece. So, whether you’re a professional metalworker or just looking to improve the appearance of your aluminum products, mastering the art of polishing is a valuable skill that is sure to pay off in the long run.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com