Table of Contents

Paragraph 1:

CNC routers are a powerful tool for manufacturing, allowing users to create intricate and precise designs with ease. However, programming a CNC router can seem daunting to those who are new to the process. In this guide, we will break down the steps needed to program a CNC router in a way that is easy to understand and follow, even for beginners.

Paragraph 2:

Whether you are a hobbyist or a professional, learning how to program a CNC router can open up a world of possibilities for your projects. By following our step-by-step guide, you will gain the knowledge and confidence needed to make the most of this powerful tool and create designs that are both beautiful and functional. So let’s dive in and get started!

- Choose a CAM software that is compatible with your CNC router.

- Create a CAD drawing of your design in the software.

- Convert the CAD drawing into a CAM program that the CNC router can understand.

- Set the cutting tool’s parameters, such as speed and depth, in the CAM program.

- Load the CAM program onto the CNC router’s computer.

- Mount the material to be cut onto the CNC router’s bed.

- Run the program and monitor the cutting process.

How to Program a CNC Router?

If you’re interested in programming a CNC router, you may be wondering where to start. A CNC router is a computer-controlled cutting machine that can be used for a variety of applications, from woodworking to metalworking. In this article, we’ll go over the basics of CNC router programming and provide tips for getting started.

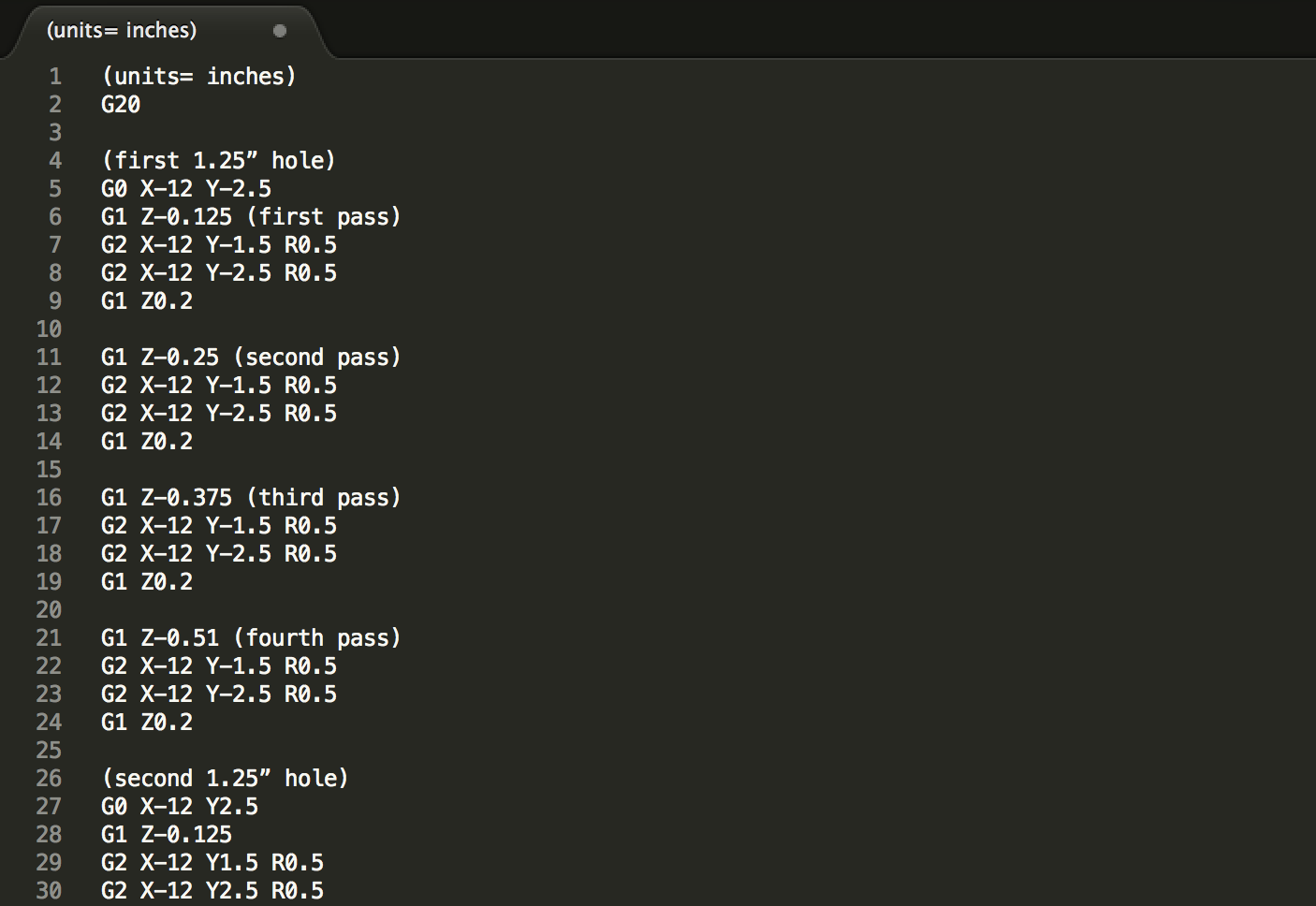

1. Understanding G-Code

The first step in programming a CNC router is understanding G-code. G-code is the programming language used to control CNC machines. It consists of a series of commands that tell the machine what to do. For example, G01 is the command for a straight line move, while G02 is the command for a clockwise arc move.

To create a G-code program, you’ll need to use a CAM (computer-aided manufacturing) software program. CAM software takes your design file and creates a G-code program based on your specifications.

The Benefits of G-Code

G-code is a universal language that can be used with any CNC machine, regardless of the manufacturer. This means you can create a program on one machine and use it on another, as long as both machines use the same G-code standard.

G-Code vs. Other Programming Languages

While G-code is the standard for CNC programming, there are other programming languages that can be used with CNC machines. However, G-code is generally considered to be the easiest to learn and use.

2. Choosing the Right Toolpath

When programming a CNC router, it’s important to choose the right toolpath for the job. A toolpath is the path that the cutting tool will take to create the desired shape. There are several different types of toolpaths, including:

– Contour toolpaths: follow the outline of the part being cut

– Pocket toolpaths: remove material from within a defined area

– Drilling toolpaths: create holes in the material

– Engraving toolpaths: create intricate designs on the surface of the material

The Benefits of Choosing the Right Toolpath

Choosing the right toolpath can help you achieve the desired result with minimal waste and maximum efficiency.

Toolpath vs. Tool

It’s important to note that a toolpath is not the same as a tool. A toolpath is the path that the cutting tool will take, while a tool is the cutting tool itself.

3. Setting the Cutting Parameters

Once you’ve chosen the right toolpath, it’s time to set the cutting parameters. Cutting parameters include:

– Spindle speed: the speed at which the spindle (the part that holds the cutting tool) rotates

– Feed rate: the rate at which the cutting tool moves through the material

– Depth of cut: the depth to which the cutting tool will penetrate the material

The Benefits of Setting the Cutting Parameters

By setting the cutting parameters correctly, you can ensure that the cutting tool will cut through the material cleanly and efficiently, without causing damage to the machine or the material.

Cutting Parameters vs. Material

It’s important to note that cutting parameters will vary depending on the material being cut. For example, you’ll need to use different cutting parameters for wood than you would for metal.

4. Testing the Program

Before running the program on your CNC router, it’s important to test it first. This will help you identify any errors or issues before they cause damage to the machine or the material. To test the program, you can use a simulation program that will show you how the cutting tool will move through the material.

The Benefits of Testing the Program

Testing the program can help you avoid costly mistakes and ensure that the finished product meets your specifications.

Testing vs. Production

It’s important to note that testing and production are two different things. While testing is important, it’s not a substitute for proper production procedures.

5. Running the Program

Once you’ve tested the program and made any necessary adjustments, it’s time to run it on your CNC router. To do this, you’ll need to load the G-code program into the machine’s controller and set up the material to be cut.

The Benefits of Running the Program

Running the program is the final step in the CNC router programming process. By following the steps outlined above, you can ensure that your program runs smoothly and produces the desired result.

Running vs. Maintenance

It’s important to note that running the program is just one part of the CNC router process. Proper maintenance is also important to ensure that the machine operates efficiently and safely.

6. Troubleshooting Common Issues

Even if you’ve followed all the steps above, you may still encounter issues when programming your CNC router. Some common issues include:

– Material not cutting cleanly

– Machine not cutting to the correct depth

– G-code program not running correctly

The Benefits of Troubleshooting

By troubleshooting common issues, you can identify the root cause of the problem and take steps to fix it. This can help you avoid costly mistakes and ensure that your finished product meets your specifications.

Troubleshooting vs. Maintenance

It’s important to note that troubleshooting is not a substitute for proper maintenance. Regular maintenance is important to ensure that your CNC router operates efficiently and safely.

7. Tips for Programming a CNC Router

When programming a CNC router, there are several tips you can follow to ensure a successful outcome. These include:

– Start with a simple design and work your way up to more complex designs

– Use a simulation program to test your program before running it on the machine

– Make sure the cutting parameters are set correctly for the material being cut

– Keep the machine and cutting tools well-maintained

The Benefits of Following These Tips

By following these tips, you can increase your chances of success and avoid costly mistakes.

Tips vs. Best Practices

It’s important to note that tips are not the same as best practices. Best practices are industry-approved methods that have been proven to be effective.

8. Advantages of CNC Router Programming

There are several advantages to programming a CNC router, including:

– Increased accuracy and precision

– Reduced waste and material costs

– Increased efficiency and productivity

– Ability to create complex designs

The Benefits of CNC Router Programming

By using a CNC router, you can achieve a high level of accuracy and precision that is difficult to achieve with manual methods. This can help you create high-quality products with minimal waste and maximum efficiency.

CNC vs. Manual Methods

While manual methods can be effective for certain tasks, CNC router programming offers several advantages over manual methods.

9. Applications of CNC Router Programming

CNC router programming can be used for a variety of applications, including:

– Woodworking

– Metalworking

– Plastics

– Composites

– Foam

– Sign-making

– Engraving

The Benefits of CNC Router Programming Applications

By using CNC router programming for these applications, you can achieve a high level of accuracy and precision that is difficult to achieve with manual methods. This can help you create high-quality products with minimal waste and maximum efficiency.

CNC Router Programming Applications vs. Manual Methods

While manual methods can be effective for certain tasks, CNC router programming offers several advantages over manual methods for these applications.

10. Conclusion

Programming a CNC router may seem daunting at first, but with the right knowledge and tools, it can be a rewarding and enjoyable experience. By following the steps outlined above and using the tips and best practices provided, you can create high-quality products with minimal waste and maximum efficiency. Whether you’re a hobbyist or a professional, CNC router programming is a valuable skill to have in today’s manufacturing industry.

Frequently Asked Questions

Programming a CNC router can be a daunting task for beginners. However, with the right knowledge and tools, it can be a rewarding experience. Here are some frequently asked questions about programming a CNC router.

What is a CNC router?

A CNC router is a computer-controlled cutting machine that can be used for various types of cutting, shaping, and carving tasks. It consists of a cutting tool, a work table, and a computer control system that guides the tool to create precise cuts and shapes on a variety of materials. CNC routers are commonly used in woodworking, metalworking, and plastic fabrication industries.

Programming a CNC router involves creating a set of instructions that tell the machine what to do. These instructions are typically written in a programming language such as G-code or CAM software, which is then sent to the machine through a computer interface.

What software is used to program a CNC router?

There are several software programs that can be used to program a CNC router. Some popular choices include AutoCAD, SolidWorks, and Mastercam. These programs allow users to create 3D models and generate tool paths that can be used to program the CNC router. Some programs also come with simulation tools that allow users to visualize the tool path and make adjustments before sending the program to the machine.

Other software programs, such as Mach3 and LinuxCNC, are specifically designed for CNC machine control and can be used to send G-code instructions directly to the machine. When selecting software, it’s important to consider the type of materials you’ll be cutting, the complexity of the job, and your skill level.

What are some basic programming concepts for CNC routers?

Before programming a CNC router, it’s important to have a basic understanding of programming concepts. Some key concepts include understanding the Cartesian coordinate system, knowing how to create and edit G-code programs, and knowing how to use CAM software to create tool paths.

Other important concepts include understanding how to set up the machine, selecting the right cutting tools, and knowing how to adjust cutting parameters such as feed rate and spindle speed. It’s also important to have a basic understanding of safety procedures and to follow all manufacturer guidelines when operating the machine.

What are some tips for programming a CNC router?

Programming a CNC router can be a complex process, but there are some tips that can help make the process smoother. First, it’s important to be organized and keep track of all programming files and tool paths. It’s also a good idea to test the program on a scrap piece of material before running it on the actual workpiece.

Other tips include selecting the right cutting tools for the job, using the correct cutting parameters, and paying attention to the cutting speed and feed rate. It’s also important to keep the machine and cutting tools clean and well-maintained, and to follow all safety procedures to avoid injury.

Where can I learn more about programming a CNC router?

There are several resources available for learning how to program a CNC router. Many community colleges and technical schools offer courses in CNC programming, and there are also online courses and tutorials available.

Other resources include CNC machine manufacturers, who often provide training and support for their products, and online forums and communities where users can ask questions and share information. It’s also a good idea to read books and articles on CNC programming to gain a deeper understanding of the subject.

In conclusion, programming a CNC router may seem daunting at first, but with the right knowledge and tools, anyone can do it. By following the steps outlined in this guide, you can start creating intricate designs and precise cuts with your CNC router in no time.

Remember to always take safety precautions when operating your machine, and double-check your code before running it. With practice, you can become a proficient CNC programmer and expand your capabilities as a maker or manufacturer.

So what are you waiting for? Get started on your CNC programming journey today and unlock the endless possibilities of this powerful tool. Happy programming!

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com