Table of Contents

- Frequently Asked Questions

- What is a weld line in injection molding?

- What are the causes of weld lines in injection molding?

- How can mold design affect the formation of weld lines?

- What role does the material selection play in reducing the formation of weld lines?

- What are some best practices for reducing weld lines in injection molding?

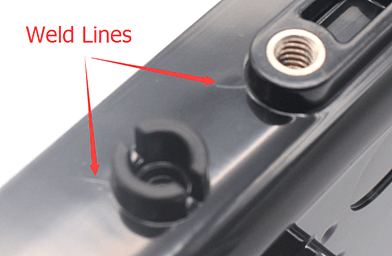

Have you ever noticed a visible line on a molded plastic product? This is called a weld line, and it occurs when two or more molten plastic streams meet during the injection molding process. Weld lines can negatively impact the appearance and strength of the final product. Fortunately, there are several ways to reduce or eliminate weld lines in injection molding. In this article, we will explore some effective techniques to help you achieve a flawless finish for your plastic parts.

To reduce weld lines in injection molding, follow these steps:

- Optimize gate location to minimize flow distance and pressure drop.

- Use a higher melt temperature to improve flow and reduce viscosity.

- Increase injection speed to reduce flow hesitation and melt cooling.

- Add a mold flow inhibitor to reduce premature solidification.

- Use a hot runner system to maintain melt temperature and reduce melt cooling.

How to Reduce Weld Line in Injection Molding?

Weld lines are a common issue that occurs in injection molding. They happen when two flow fronts of melted plastic meet and solidify, leaving a visible line on the surface of the part. These lines can weaken the strength of the part, and they can also be unsightly. Fortunately, there are several ways to reduce weld lines in injection molding.

1. Increase the Melt Temperature

The melt temperature is the temperature at which the plastic is injected into the mold. Increasing the melt temperature can help to reduce weld lines. This is because a higher melt temperature will help to reduce the viscosity of the plastic, which in turn will help to reduce the amount of pressure required for the plastic to flow.

It is important to note that increasing the melt temperature too much can cause other issues, such as burning or degradation of the plastic. It is important to find the right balance for your specific material and mold.

2. Increase Injection Speed

Another way to reduce weld lines is to increase the injection speed. This will help to reduce the amount of time that the two flow fronts have to solidify before they meet.

It is important to note that increasing the injection speed too much can cause other issues, such as flash or short shots. It is important to find the right balance for your specific material and mold.

3. Increase Pressure

Increasing the pressure can also help to reduce weld lines. This is because a higher pressure will help to ensure that the plastic fills the mold completely before solidifying.

It is important to note that increasing the pressure too much can cause other issues, such as sink marks or warpage. It is important to find the right balance for your specific material and mold.

4. Increase the Gate Size

The gate is the point at which the plastic enters the mold. Increasing the gate size can help to reduce weld lines. This is because a larger gate will allow the plastic to flow more easily, which will help to reduce the amount of pressure required for the plastic to flow.

It is important to note that increasing the gate size too much can cause other issues, such as flash or short shots. It is important to find the right balance for your specific material and mold.

5. Use a Hot Runner System

A hot runner system is a system in which the plastic is kept molten in the runner system, rather than solidifying after it enters the mold. This can help to reduce weld lines, as the plastic is able to flow more easily and fill the mold completely.

It is important to note that hot runner systems can be more expensive than traditional runner systems, but they can be worth the investment if you are having issues with weld lines.

6. Modify the Part Design

Sometimes, modifying the part design can help to reduce weld lines. This can include changing the location of the gate, adding ribs to the part, or changing the shape of the part.

It is important to work with your design team to find the best solution for your specific part.

7. Use a Different Material

Sometimes, using a different material can help to reduce weld lines. This can be because the material has a lower viscosity or a higher melt temperature.

It is important to test any new materials thoroughly before using them in production.

8. Reduce the Wall Thickness

Reducing the wall thickness can also help to reduce weld lines. This is because a thinner wall will allow the plastic to flow more easily and fill the mold completely.

It is important to note that reducing the wall thickness too much can cause other issues, such as sink marks or warpage. It is important to find the right balance for your specific part.

9. Use a Mold Release Agent

Using a mold release agent can also help to reduce weld lines. This is because the release agent will help to reduce the surface tension of the plastic, which will help to reduce the amount of pressure required for the plastic to flow.

It is important to note that some mold release agents can cause other issues, such as flash or short shots. It is important to test any new release agents thoroughly before using them in production.

10. Work with an Experienced Molder

Working with an experienced molder can help to ensure that your parts are produced with minimal weld lines. An experienced molder will be able to identify any issues with your mold or material, and they will be able to make recommendations for improving the part design or production process.

It is important to choose a molder that has experience with your specific material and part design.

In conclusion, reducing weld lines in injection molding requires a combination of factors, including adjusting the melt temperature, injection speed, pressure, and gate size, as well as using a hot runner system, modifying the part design, using a different material, reducing the wall thickness, using a mold release agent, and working with an experienced molder. By taking these steps, you can produce high-quality parts with minimal weld lines.

Frequently Asked Questions

Injection molding is a widely used manufacturing process. However, the process can lead to the formation of weld lines, which can affect the appearance and strength of the final product. Here are some frequently asked questions and answers on how to reduce weld line in injection molding:

What is a weld line in injection molding?

A weld line is a line that forms when two or more flows of molten plastic meet and solidify. The flow of molten plastic can be interrupted by obstacles such as inserts, ribs, or bosses, causing a weld line to form. Weld lines can affect the appearance and strength of the final product, and can lead to failure under stress.

To reduce the formation of weld lines, it is important to optimize the injection molding process. This can include adjusting the temperature, pressure, and speed of injection, as well as the design of the mold and the placement of inserts, ribs, and bosses.

What are the causes of weld lines in injection molding?

The formation of weld lines in injection molding can be caused by a number of factors. These can include interruptions in the flow of molten plastic due to inserts, ribs, or bosses, as well as changes in temperature, pressure, and speed of injection. The design of the mold can also play a role in the formation of weld lines.

To reduce the formation of weld lines, it is important to carefully analyze the design of the mold and the placement of inserts, ribs, and bosses. It may be necessary to adjust the temperature, pressure, and speed of injection to ensure a smooth and uninterrupted flow of molten plastic.

How can mold design affect the formation of weld lines?

The design of the mold can play a significant role in the formation of weld lines in injection molding. The placement of inserts, ribs, and bosses can interrupt the flow of molten plastic, leading to the formation of weld lines. The shape and size of the mold can also affect the flow of plastic and the formation of weld lines.

To reduce the formation of weld lines, it is important to carefully analyze the design of the mold and the placement of inserts, ribs, and bosses. The shape and size of the mold should be optimized to ensure a smooth and uninterrupted flow of molten plastic.

What role does the material selection play in reducing the formation of weld lines?

The selection of the material for injection molding can play a role in reducing the formation of weld lines. Some materials are more prone to the formation of weld lines than others. Materials with a higher melt flow rate tend to flow more easily and can reduce the formation of weld lines.

To reduce the formation of weld lines, it is important to carefully select the material for injection molding. Materials with a higher melt flow rate and good flow properties can help to reduce the formation of weld lines.

What are some best practices for reducing weld lines in injection molding?

There are several best practices for reducing the formation of weld lines in injection molding. These include optimizing the injection molding process, carefully analyzing the design of the mold and the placement of inserts, ribs, and bosses, selecting materials with good flow properties, and conducting regular maintenance and cleaning of the mold.

By following these best practices, it is possible to reduce the formation of weld lines in injection molding and improve the appearance and strength of the final product.

In conclusion, reducing weld lines in injection molding is crucial to achieve high-quality products. By understanding the factors that contribute to weld line formation, such as gate placement and part design, manufacturers can take proactive steps to minimize their occurrence.

One effective method to reduce weld lines is by adjusting the injection molding process parameters, such as temperature and pressure. Fine-tuning these settings can help ensure that the molten plastic flows smoothly through the mold, minimizing the risk of weld line formation.

Moreover, choosing the right type of plastic material can also help minimize weld lines. Some materials have a lower viscosity, making them less prone to creating weld lines during the molding process. By considering these factors and taking a proactive approach, manufacturers can produce high-quality injection-molded parts with minimal defects.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com