Table of Contents

- Freequently Asked Questions

- What are the steps involved in setting up a CNC plasma cutter?

- What are the safety precautions to be taken while setting up a CNC plasma cutter?

- What are the benefits of using a CNC plasma cutter?

- What are the key components of a CNC plasma cutter?

- What are some common problems that can occur when setting up a CNC plasma cutter?

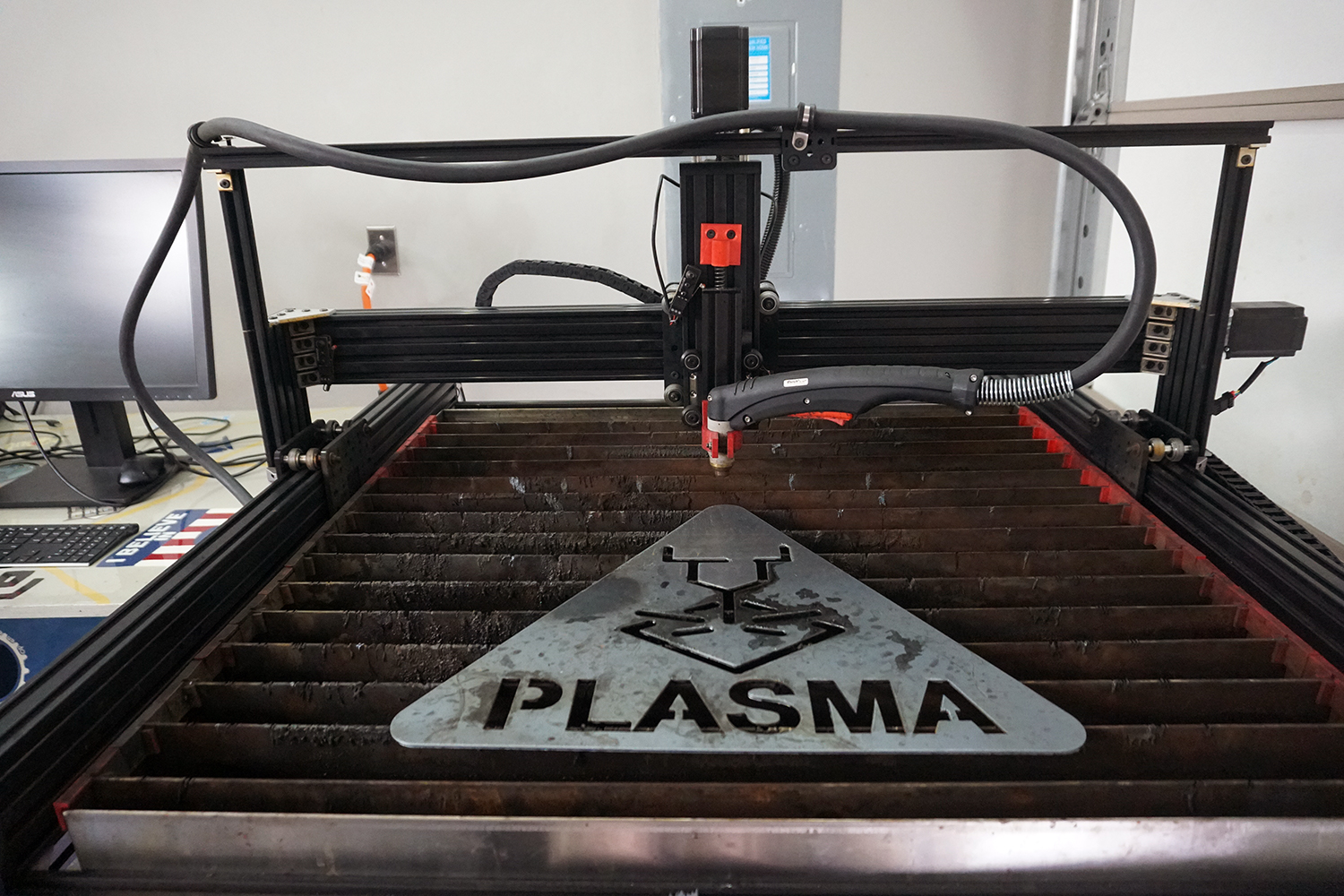

If you are looking for an efficient way to cut through metal like butter, a CNC plasma cutter might just be the answer to your needs. Whether you’re a DIY enthusiast or a business owner, setting up a CNC plasma cutter can be a game-changer for your projects.

In this guide, we’ll go through the step-by-step process of setting up a CNC plasma cutter. From choosing the right machine to installing the software and getting it ready for use, we’ve got you covered. So, let’s dive in and get started on this exciting journey!

- Choose the right location for your cutter, making sure there’s enough space for the machine and that it’s in a well-ventilated area.

- Install the software that comes with the cutter, and follow the instructions to connect it to your computer.

- Attach the plasma torch to the machine and make sure it’s secured properly.

- Adjust the settings on the software and test the machine to ensure that it’s working correctly.

- Load your design into the software and start cutting!

How to Set Up a CNC Plasma Cutter?

Setting up a CNC plasma cutter can seem like a daunting task, but with the right tools and knowledge, it can be done with ease. In this article, we will guide you through the necessary steps to set up your CNC plasma cutter.

Step 1: Assemble the Plasma Cutter

The first step in setting up your CNC plasma cutter is to assemble the machine. Start by unpacking all the parts and checking that you have everything you need. Once you have confirmed that everything is there, follow the manufacturer’s instructions to assemble the machine.

Next, connect the power supply to the machine and plug it in. Make sure you have the correct voltage for your machine, as this can vary depending on the model. Then, attach the ground wire to the machine and connect it to a suitable grounding point.

Step 2: Install the Software

The next step is to install the software that will control the CNC plasma cutter. This software is typically provided with the machine and can be installed on a computer. Follow the manufacturer’s instructions to install the software, and make sure to download any updates or patches that are available.

Once the software is installed, connect the computer to the machine using a USB cable. Make sure the connection is secure, and the computer recognizes the machine. You should now be ready to start using your CNC plasma cutter.

Step 3: Configure the Settings

Before you can start cutting, you need to configure the settings for the machine. This includes setting the cutting speed, torch height, and amperage. These settings will vary depending on the material you are cutting and the thickness of the material.

To configure the settings, consult the manufacturer’s instructions or software manual. You may also need to adjust the settings as you go along, depending on the results of your cuts.

Step 4: Load the Material

The next step is to load the material onto the CNC plasma cutter. This involves clamping the material onto the machine’s work table, making sure it is secure and level. You may also need to attach a magnetic or suction clamp to hold the material in place.

Once the material is loaded, adjust the torch height to the correct distance from the material. This will ensure the plasma cutter cuts at the correct depth and produces clean, accurate cuts.

Step 5: Test the Machine

Before you start cutting your project, it’s a good idea to test the machine on a small piece of scrap material. This will allow you to ensure that the settings are correct and that the machine is working correctly.

To test the machine, use the software to create a simple design and cut it out of the scrap material. Check the results of the cut and make any necessary adjustments to the settings before starting your project.

Step 6: Start Cutting

With the machine set up and tested, you are now ready to start cutting your project. Use the software to create the design you want to cut, and then load the material onto the machine.

Make sure the material is secure and the torch height is set correctly. Then, start the cutting process and let the machine do its work. Be sure to monitor the machine throughout the cutting process to ensure it is cutting correctly and making clean, accurate cuts.

Step 7: Finishing the Cut

Once the cut is complete, you will need to remove the material from the machine and clean up any debris. Use a scraper or wire brush to remove any slag or residue left on the cut edges.

If necessary, you can also sand or file the edges of the cut material to smooth them out. This will give your project a professional, finished look.

Step 8: Maintenance

To keep your CNC plasma cutter working at its best, it’s important to perform regular maintenance. This includes cleaning the machine after each use, checking the torch height and amperage, and replacing any worn or damaged parts.

Consult the manufacturer’s instructions for specific maintenance recommendations, and be sure to follow them carefully.

Step 9: Benefits of a CNC Plasma Cutter

Using a CNC plasma cutter has many benefits over traditional cutting methods. These include faster cutting speeds, more accurate cuts, and the ability to cut complex shapes and designs.

CNC plasma cutters are also more efficient and cost-effective than other cutting methods, as they require less material and produce less waste. They are also easy to use and require minimal training, making them a great choice for both professional and hobbyist use.

Step 10: CNC Plasma Cutter vs. Other Cutting Methods

Compared to other cutting methods, such as laser cutting or waterjet cutting, CNC plasma cutting has several advantages. It is less expensive to operate and maintain, and it can cut thicker materials than laser cutting.

While waterjet cutting can cut thicker materials than plasma cutting, it is a slower process and requires more maintenance. CNC plasma cutting is also more versatile than waterjet cutting, as it can cut a wider range of materials.

In conclusion, setting up a CNC plasma cutter may seem like a daunting task, but with the right tools and knowledge, it can be done with ease. By following these steps and consulting the manufacturer’s instructions, you can have your CNC plasma cutter up and running in no time, producing clean, accurate cuts for all your projects.

Freequently Asked Questions

Here are some commonly asked questions and answers about how to set up a CNC plasma cutter:

What are the steps involved in setting up a CNC plasma cutter?

Setting up a CNC plasma cutter involves several steps. First, you need to mount the plasma torch on the Z-axis of the machine. Then, you need to connect the torch to the plasma power supply, which is responsible for generating the plasma arc. After that, you need to calibrate the machine by setting the distance between the torch and the workpiece, as well as the speed and the height of the torch. Finally, you need to install the necessary software and configure the machine settings.

Once you have completed these steps, you are ready to start cutting. However, it is important to note that the setup process may vary depending on the specific model and brand of the CNC plasma cutter.

What are the safety precautions to be taken while setting up a CNC plasma cutter?

When setting up a CNC plasma cutter, it is important to take appropriate safety precautions to avoid accidents and injuries. First, you should wear appropriate protective gear, including gloves, safety glasses, and a welding helmet. You should also ensure that the work area is well-ventilated and free of flammable materials.

In addition, you should be careful when connecting the plasma torch to the power supply, as the high voltage can be dangerous. Make sure to follow the manufacturer’s instructions carefully and use a ground clamp to prevent electrical shock. Finally, you should never leave the machine unattended while it is in operation and always follow proper shutdown procedures.

What are the benefits of using a CNC plasma cutter?

CNC plasma cutters offer several benefits over traditional cutting methods. First, they allow for greater precision and accuracy, as the machine can follow complex patterns and designs with ease. They also offer faster cutting speeds and can handle a wide range of materials, including steel, aluminum, and copper.

In addition, CNC plasma cutters are more efficient and cost-effective than manual cutting methods, as they require less labor and waste. They also offer greater consistency and repeatability, which is important for mass production and manufacturing processes.

What are the key components of a CNC plasma cutter?

A CNC plasma cutter consists of several key components, including the plasma power supply, the torch, the Z-axis, the controller, and the software. The plasma power supply is responsible for generating the plasma arc, while the torch delivers the arc to the workpiece.

The Z-axis controls the height of the torch, and the controller manages the movement of the machine. The software is used to program the machine and control the cutting process. Other components may include a water table, which is used to reduce heat and noise during cutting, and a dust collector, which removes debris and fumes from the work area.

What are some common problems that can occur when setting up a CNC plasma cutter?

Setting up a CNC plasma cutter can be a complex process, and there are several common problems that can occur. These may include issues with the torch height, which can affect the quality of the cut, as well as problems with the power supply, which can cause the arc to drop out or become unstable.

Other problems may include issues with software compatibility or configuration, as well as problems with the machine’s mechanical components. To avoid these issues, it is important to carefully follow the manufacturer’s instructions and consult with an expert if necessary. Regular maintenance and calibration can also help prevent problems from occurring.

In conclusion, setting up a CNC plasma cutter may seem daunting at first, but with the right tools and knowledge, it can be a straightforward process. Remember to carefully read the instructions and safety guidelines before starting. Take your time to calibrate the machine and ensure that the power supply and air compressor are properly connected. With practice, you will be able to create intricate and precise cuts that will take your projects to the next level.

Furthermore, proper maintenance of your CNC plasma cutter is crucial to its longevity and performance. Regularly clean the machine and replace worn parts to ensure that it continues to work at its best. Familiarize yourself with the software and keep it updated to take advantage of the latest features.

Finally, don’t be afraid to experiment and try new things with your CNC plasma cutter. From custom signs and metal art to industrial parts and prototypes, the possibilities are endless. With a little creativity and determination, you can achieve amazing results with your machine. So go ahead and dive into the world of CNC plasma cutting – the journey is just beginning!

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com