Table of Contents

CNC router bits are an essential tool for any woodworker, but over time they can become dull and less effective. Sharpening your bits is an important skill to learn to keep your projects looking professional and precise.

In this article, we’ll explore the different types of CNC router bits, the signs that your bits need sharpening, and step-by-step instructions for how to sharpen them at home. Whether you’re a seasoned woodworker or just starting out, this guide will help you keep your bits sharp and ready to use on your next project.

- First, ensure safety by wearing protective gloves and eyewear.

- Use a diamond-coated grinding wheel to sharpen the bit, turning it clockwise against the wheel.

- Be sure to sharpen both flutes evenly for the best results.

- Check the bit’s sharpness by running a fingernail across the edge. If it catches, it’s sharp.

- Finally, clean the bit with a soft cloth and store it in a safe place.

How to Sharpen CNC Router Bits?

If you work with CNC routers, you know that dull bits can ruin your work and waste your time. That’s why it’s essential to keep your router bits sharp. In this article, we’ll go over the steps you need to take to sharpen your CNC router bits.

1. Determine the Type of Bit

Before you start sharpening, you need to know what type of bit you’re dealing with. There are three main types of bits: straight, spiral, and flush trim. Each type requires a different sharpening technique.

Straight bits can be sharpened with a sharpening stone or a diamond file. Spiral bits, on the other hand, are sharpened with a diamond file or a special sharpening tool. Flush trim bits require a different technique altogether, which we’ll cover later in this article.

Benefits of Using a Sharpening Stone

Using a sharpening stone is an affordable and effective way to sharpen straight bits. It’s also a skill that can be learned quickly, so you can save money on professional sharpening services.

Straight Bit Sharpening Process

To sharpen a straight bit with a sharpening stone, follow these steps:

- Secure the bit in a vice.

- Stroke the sharpening stone along the cutting edge of the bit.

- Flip the bit over and repeat the process on the other side.

- Check the sharpness of the bit by running your finger along the cutting edge.

- Repeat the process until the bit is sharp.

2. Sharpening Spiral Bits

Sharpening spiral bits requires a bit more skill and a special sharpening tool. Here’s how to do it:

Benefits of Using a Special Sharpening Tool

Special sharpening tools are designed to sharpen spiral bits quickly and accurately. They’re also easy to use, so you don’t need to be a professional to sharpen your bits.

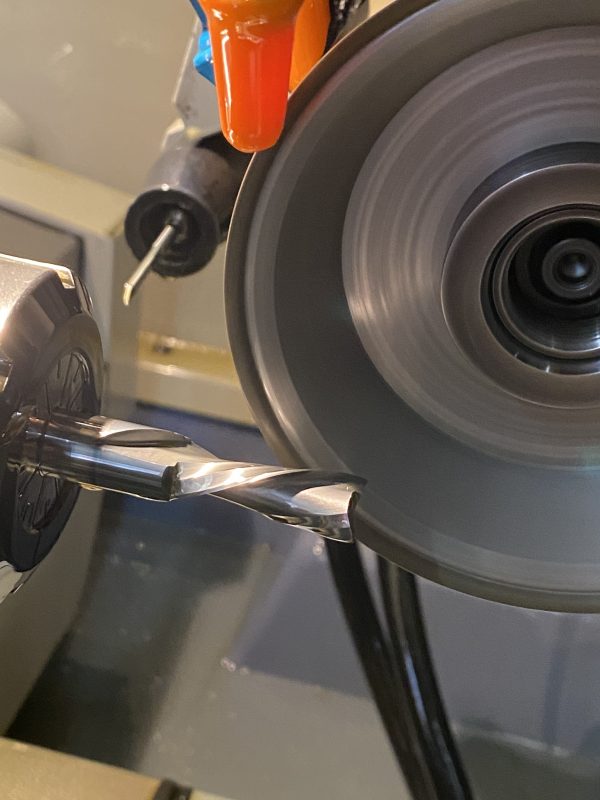

Spiral Bit Sharpening Process

To sharpen a spiral bit with a special sharpening tool, follow these steps:

- Insert the bit into the sharpening tool.

- Adjust the sharpening tool to the correct angle.

- Turn on the sharpening tool and run the bit through it.

- Check the sharpness of the bit by running your finger along the cutting edge.

- Repeat the process until the bit is sharp.

3. Sharpening Flush Trim Bits

Flush trim bits are used to trim the edge of a piece of material flush with another surface. They require a different sharpening technique than other bits. Here’s how to sharpen a flush trim bit:

Benefits of Using a Specialty Jig

A specialty jig is designed to hold the flush trim bit securely and at the correct angle for sharpening. It ensures that the bit is sharpened evenly and accurately.

Flush Trim Bit Sharpening Process

To sharpen a flush trim bit with a specialty jig, follow these steps:

- Secure the jig to a workbench.

- Insert the bit into the jig and adjust the angle.

- Use a sharpening stone or diamond file to sharpen the cutting edge.

- Flip the bit over and repeat the process on the other side.

- Check the sharpness of the bit by running your finger along the cutting edge.

- Repeat the process until the bit is sharp.

4. Tips for Keeping Your Bits Sharp

Sharpening your bits is an essential part of keeping them in good working condition, but there are other things you can do to extend their lifespan:

Benefits of Using a Dust Collector

Using a dust collector can help keep your bits clean and free of debris, which can cause them to dull more quickly.

Benefits of Using High-Quality Bits

Investing in high-quality bits can save you money in the long run. They’re less likely to dull quickly, which means you won’t have to sharpen them as often.

Benefits of Proper Maintenance

Proper maintenance, such as cleaning and lubricating your bits, can help prevent them from dulling prematurely.

In conclusion, sharpening your CNC router bits is an essential part of keeping your equipment in good working condition. By following the steps outlined in this article and taking care of your bits, you can ensure that your work is always precise and of high quality.

Frequently Asked Questions

Below are the most commonly asked questions about how to sharpen CNC router bits:

What is a CNC Router Bit?

A CNC router bit is a cutting tool that is specifically designed for use with a CNC router machine. These bits are made from high-speed steel or carbide and come in a variety of shapes and sizes.

The bits are used to cut and shape materials such as wood, plastic, and metal. They are an essential part of the CNC router machine and need to be kept sharp to ensure the best possible performance.

Why is it important to sharpen CNC router bits?

Sharpening your CNC router bits is essential to maintain the quality and accuracy of your cuts. Dull bits can cause the material to tear or produce rough cuts, which can ruin the final product.

Sharpening the bits regularly will also help prolong their lifespan, saving you money in the long run by avoiding the need to replace them as frequently.

How often should CNC router bits be sharpened?

The frequency with which you need to sharpen your CNC router bits will depend on how often you use them and the type of material you are cutting.

As a general rule, it is recommended to sharpen your bits after every 8 hours of use. However, you may need to sharpen them more or less frequently depending on your specific needs.

What are the different methods for sharpening CNC router bits?

There are several methods for sharpening CNC router bits, including using a diamond file or sharpening stone, a bench grinder, or a specialized bit sharpener machine.

Each method has its own advantages and disadvantages, and the best method for you will depend on your budget, skill level, and the type of bits you are sharpening.

Can I sharpen my own CNC router bits, or should I seek professional help?

While it is possible to sharpen your own CNC router bits, it can be a challenging and time-consuming task, especially if you are not familiar with the process.

If you are not confident in your ability to sharpen the bits yourself, it is recommended to seek professional help. A professional sharpening service will have the expertise and specialized equipment needed to sharpen your bits to the highest standard.

In conclusion, sharpening CNC router bits is an essential process that should not be overlooked. It not only saves you money by prolonging the life of your bits but also ensures quality cuts and precision in your work. By following the steps outlined in this guide, you can effectively sharpen your CNC router bits and achieve optimal performance from your machine.

Remember, safety should always come first when handling any tools. Always wear protective gear and follow the manufacturer’s instructions when sharpening your CNC router bits. With a little bit of practice and patience, you can become an expert in sharpening your bits and take your woodworking projects to the next level.

Lastly, don’t forget to maintain your bits regularly to prevent them from getting dull in the first place. Keep them clean and dry, and store them properly to avoid any damage. By doing so, you’ll save yourself time and money in the long run and ensure that your CNC router is always performing at its best.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com