Table of Contents

- How to Soundproof a CNC Machine?

- Frequently Asked Questions

- What is soundproofing and why is it important for CNC machines?

- What are some common materials used for soundproofing a CNC machine?

- How can I determine the level of noise produced by my CNC machine?

- Can soundproofing a CNC machine affect its performance?

- Do I need professional help to soundproof my CNC machine?

Do you have a noisy CNC machine that is disrupting your workplace? Whether your machine is in a small workshop or a large factory, soundproofing it can make a big difference in reducing noise pollution. In this guide, we will walk you through the steps of soundproofing your CNC machine so you can work in peace and quiet.

With the rise of technology, CNC machines have become an integral part of various industries. However, the noise produced by these machines can be a major source of discomfort for workers. That’s why it’s important to take steps to soundproof your CNC machine. Not only will it improve the working environment, but it can also reduce the risk of hearing damage caused by prolonged exposure to loud noise. So, let’s get started on soundproofing your CNC machine!

- Start by inspecting the machine and identifying the noise sources.

- Use sound-absorbing materials such as acoustic foam, mass loaded vinyl, or fiberglass to cover the machine’s panels and walls.

- Add vibration dampening pads or mounts to isolate the machine’s vibration from the surrounding environment.

- Utilize noise barriers such as curtains, enclosures, or soundproof booths to reduce noise transmission from the machine.

- Ensure proper maintenance of the machine, including lubrication and tightening of loose parts, to minimize noise levels.

How to Soundproof a CNC Machine?

If you own a CNC machine, you know how important it is to keep it running smoothly and quietly. However, the noise generated by the machine can be a nuisance, especially if you work in a shared space or residential area. Fortunately, there are several effective ways to soundproof your CNC machine and reduce the noise it produces.

1. Use Soundproofing Materials

One of the most effective ways to soundproof your CNC machine is to use soundproofing materials. These materials can be used to absorb or block sound waves, reducing the noise generated by the machine. Some of the most common soundproofing materials include:

– Acoustic foam: This is a popular soundproofing material that can be used to absorb sound waves. It is available in different thicknesses and densities, making it easy to customize for your specific needs.

– Mass-loaded vinyl: This is a heavy-duty material that can be used to block sound waves. It is often used in combination with other soundproofing materials.

– Soundproof curtains: These curtains are made of heavy-duty fabric and can be used to absorb sound waves.

2. Build a Sound Barrier

Another effective way to soundproof your CNC machine is to build a sound barrier around it. This can be done using materials like drywall, plywood, or even concrete. The key is to create a solid barrier that will reflect or absorb the sound waves generated by the machine.

3. Install Vibration Dampeners

The vibration generated by your CNC machine can also contribute to the noise it produces. To reduce this noise, you can install vibration dampeners on the machine. These can be in the form of rubber feet or pads that absorb the vibration and reduce the noise.

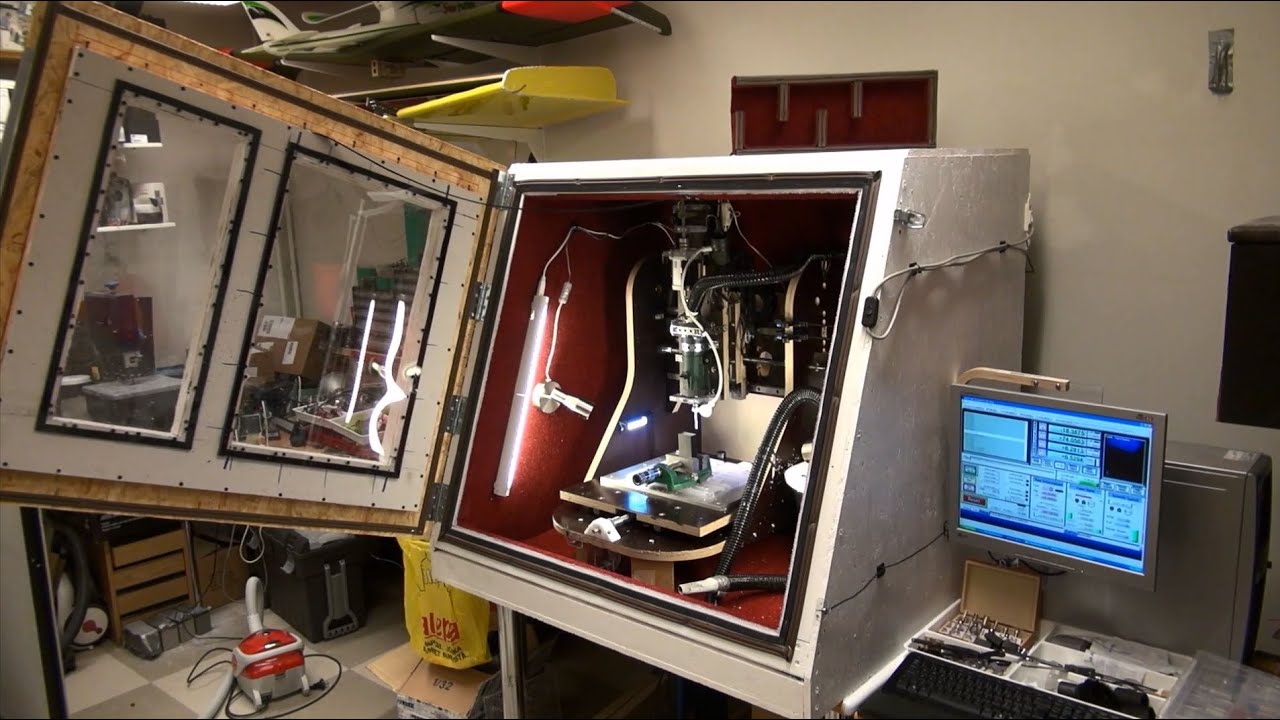

4. Use Enclosures

Another effective way to soundproof your CNC machine is to use an enclosure. This can be a simple box or a more elaborate structure that surrounds the machine. The enclosure can be made of soundproofing materials or simply be a solid barrier that blocks the sound waves.

5. Maintain Your Machine

Regular maintenance of your CNC machine can also help to reduce the noise it produces. This includes things like lubricating moving parts, tightening loose bolts, and replacing worn-out components. A well-maintained machine will operate more efficiently and quietly.

6. Consider Location

The location of your CNC machine can also contribute to the noise it produces. If possible, try to locate the machine in an area that is separated from other workspaces or living areas. This can help to reduce the impact of the noise on others.

7. Upgrade Your Machine

If your CNC machine is old or outdated, it may be contributing to the noise it produces. Upgrading to a newer, more efficient machine can help to reduce the noise and improve overall performance.

8. Use Noise-Canceling Headphones

If you are unable to reduce the noise generated by your CNC machine, you can still protect your hearing by using noise-canceling headphones. These headphones use advanced technology to cancel out the noise around you, allowing you to work in relative peace and quiet.

9. Consider Legal Requirements

In some cases, there may be legal requirements for reducing the noise generated by your CNC machine. This may include local noise ordinances or workplace safety regulations. Be sure to check with your local authorities to ensure that you are complying with any applicable regulations.

10. Benefits of Soundproofing Your CNC Machine

Soundproofing your CNC machine can provide several benefits, including:

– Improved productivity: A quieter workspace can help to improve productivity by reducing distractions and allowing employees to focus on their work.

– Protecting your hearing: Exposure to loud noise can cause long-term hearing damage. Soundproofing your CNC machine can help to protect your hearing.

– Compliance with regulations: Depending on your location and industry, there may be legal requirements for reducing noise levels in the workplace.

– Better customer experience: If you operate a business that uses a CNC machine, reducing the noise it produces can help to create a more comfortable and welcoming environment for your customers.

In conclusion, soundproofing your CNC machine is a worthwhile investment that can help to improve productivity, protect your hearing, and ensure compliance with regulations. By using a combination of soundproofing materials, sound barriers, vibration dampeners, and enclosures, you can reduce the noise generated by your machine and create a more peaceful workspace.

Frequently Asked Questions

Here are some commonly asked questions about soundproofing a CNC machine:

What is soundproofing and why is it important for CNC machines?

Soundproofing is the process of reducing the amount of noise that escapes from a machine or room. It is important for CNC machines because they produce a lot of noise that can be disruptive to workers and nearby residents. Additionally, reducing noise can help prevent hearing damage and improve the overall working environment.

There are several methods for soundproofing a CNC machine, including adding insulation to the walls and ceiling, installing acoustic panels, and using sound barriers. It is important to choose the method that is most effective for your specific machine and environment.

What are some common materials used for soundproofing a CNC machine?

There are several materials that can be used for soundproofing a CNC machine, including acoustic foam, mass loaded vinyl, and fiberglass insulation. Acoustic foam is a popular choice because it is affordable and easy to install. Mass loaded vinyl is another option that is effective at reducing noise, but it can be more expensive. Fiberglass insulation is a versatile material that can be used for both thermal and sound insulation. However, it can be messy to install and may require professional help.

When choosing materials for soundproofing, it is important to consider factors such as cost, effectiveness, and ease of installation. It may be helpful to consult with a professional to determine the best option for your specific needs.

How can I determine the level of noise produced by my CNC machine?

There are several tools that can be used to measure the level of noise produced by a CNC machine, including sound level meters and noise dosimeters. A sound level meter measures the intensity of sound in decibels (dB) and can be used to determine the overall noise level of a machine. A noise dosimeter is a specialized device that measures the amount of noise exposure over a period of time.

Once you have determined the level of noise produced by your CNC machine, you can begin to explore methods for reducing noise and improving the working environment.

Can soundproofing a CNC machine affect its performance?

Soundproofing a CNC machine can affect its performance if done incorrectly. For example, adding too much insulation or using the wrong materials can lead to overheating and reduced efficiency. It is important to choose materials that are safe for use with your specific machine and to follow manufacturer guidelines for installation.

Additionally, it is important to consider the impact of soundproofing on ventilation and air flow. Adequate ventilation is necessary to prevent overheating and maintain optimal performance.

Do I need professional help to soundproof my CNC machine?

While it is possible to soundproof a CNC machine on your own, it may be helpful to consult with a professional for best results. A professional can help you determine the most effective methods of soundproofing for your specific machine and environment. Additionally, they can ensure that the materials used are safe and do not negatively impact performance.

Hiring a professional may be particularly beneficial if you have limited experience with soundproofing or if you are working with a large or complex machine.

In conclusion, soundproofing your CNC machine is an essential task for a quieter and more efficient workplace. With the right materials and techniques, you can reduce the noise level of your machine significantly.

First, start by identifying the sources of noise and their frequency range, so you can choose the best soundproofing materials for your machine. Next, consider using vibration-dampening pads or mounts to reduce the impact of the machine’s vibrations on the surrounding area. Finally, take the time to seal any gaps or openings in the machine’s enclosure to prevent sound from leaking out.

Remember, soundproofing your CNC machine is not only about reducing noise pollution, but it can also improve the accuracy and lifespan of your machine. By following these simple steps, you can create a quieter and more productive workspace for you and your team.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com