Table of Contents

CNC routers have revolutionized the world of manufacturing by allowing for precise cuts and designs. However, to achieve this accuracy, it is crucial to ensure that your CNC router is properly trammed. Tramming refers to the process of aligning the machine’s spindle to its table, and a misaligned machine can lead to inaccurate cuts and wasted materials.

In this guide, we will take you through the steps of how to tram a CNC router. Whether you are a seasoned professional or a beginner, our easy-to-follow instructions will help you get the most out of your CNC router and ensure that your projects are completed with precision and accuracy. So, let’s dive in and get started!

How to Tram a CNC Router?

Tramming a CNC router is an essential maintenance task that every CNC machine owner should know how to do. Tramming ensures that the spindle is perpendicular to the work surface, allowing for accurate and precise cuts. In this article, we’ll go over the steps required to tram a CNC router.

What is Tramming?

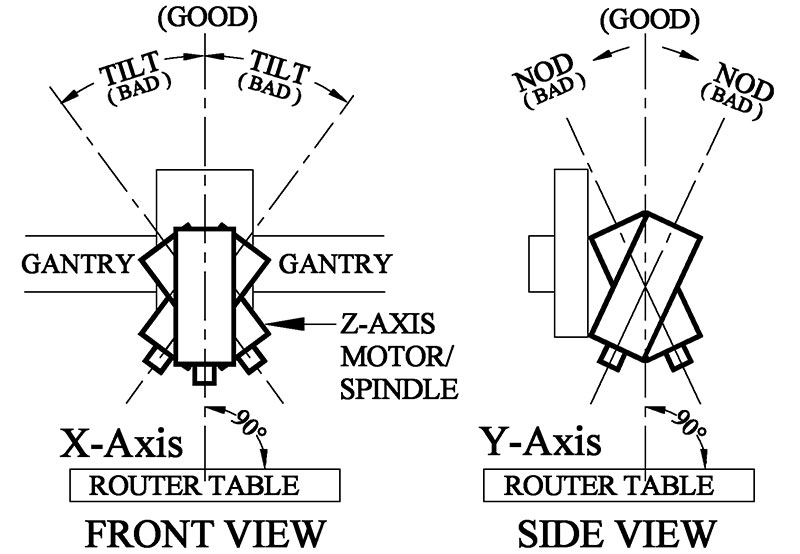

Tramming is the process of aligning the spindle of a CNC router perpendicular to the work surface. This is important because a misaligned spindle can cause cuts to be off-center or at an angle, resulting in inaccurate and imprecise cuts. Tramming is typically done using a dial indicator to measure the distance between the spindle and the work surface at various points on the table.

To tram a CNC router, you’ll need a few tools and supplies. These include a dial indicator, a magnetic base, a spanner wrench, and a piece of paper or shim stock.

First, you’ll need to mount the dial indicator on the spindle. This is typically done using a magnetic base that attaches to the spindle. Once the dial indicator is mounted, you’ll need to adjust it so that the stylus is touching the work surface.

Measuring the Distance

To measure the distance between the spindle and the work surface, you’ll need to move the spindle to various points on the table. You can do this manually, or you can use the CNC machine’s software to move the spindle automatically.

Once the spindle is in position, you’ll need to zero the dial indicator. This is typically done by rotating the bezel on the dial indicator until the needle points to zero. Then, you’ll need to move the spindle to another point on the table and take another measurement.

Repeat this process at several points on the table, taking note of the measurements at each point. You’ll want to make sure that the measurements are consistent across the table. If you notice any significant variations, you’ll need to adjust the tramming.

Adjusting the Tramming

To adjust the tramming, you’ll need to use a spanner wrench to loosen the bolts that hold the spindle in place. Once the bolts are loose, you can adjust the position of the spindle to bring it into alignment.

To determine how much adjustment is needed, you’ll need to calculate the difference between the highest and lowest measurements you took during the tramming process. Divide this number by two, and that will give you the amount of adjustment needed to bring the spindle into alignment.

Once you’ve made the necessary adjustments, you’ll need to re-measure the distance between the spindle and the work surface to ensure that it’s now perpendicular.

Benefits of Tramming

Tramming your CNC router is essential for achieving accurate and precise cuts. A misaligned spindle can cause cuts to be off-center or at an angle, resulting in wasted material and increased production time. By tramming your CNC router, you’ll be able to achieve consistent and high-quality cuts every time.

Tramming vs. Calibration

It’s important to note that tramming is not the same as calibration. Tramming refers to the alignment of the spindle perpendicular to the work surface, while calibration involves ensuring that the machine is cutting to the correct dimensions.

While both tramming and calibration are essential maintenance tasks for your CNC router, they are different processes that require different tools and techniques.

Conclusion

Tramming your CNC router is an essential maintenance task that every CNC machine owner should know how to do. By following the steps outlined in this article, you’ll be able to ensure that your spindle is perpendicular to the work surface, allowing for accurate and precise cuts. Tramming is a simple process that can have a significant impact on the quality of your work, so be sure to make it a regular part of your maintenance routine.

Freequently Asked Questions

Tramming a CNC router is an important step in ensuring accurate and precise cuts. Here are some frequently asked questions and their answers to help you with the process.

What is Tramming?

Tramming is the process of aligning the CNC router’s spindle with the bed of the machine. This is important because if the spindle is not aligned properly, it can lead to inaccurate cuts and uneven edges.

To tram a CNC router, you will need to use a tramming tool, such as a dial indicator or a laser, to measure the distance between the spindle and the bed at various points. Once you have these measurements, you can adjust the machine’s settings to ensure that the spindle is aligned properly.

Why is Tramming Important?

Tramming is important because it ensures that your cuts are accurate and precise. If the spindle is not aligned properly, it can lead to uneven edges, which can ruin your project. Additionally, a misaligned spindle can cause the bit to break or wear down more quickly, which can be expensive and time-consuming to replace.

By taking the time to tram your CNC router, you can save yourself time and money in the long run by ensuring that your machine is working properly and producing high-quality cuts.

How Often Should I Tram My CNC Router?

How often you need to tram your CNC router will depend on how frequently you use it and how much wear and tear it experiences. As a general rule, you should plan to tram your machine at least once every six months. However, if you notice that your cuts are becoming less accurate or that the spindle is not working as well as it used to, it may be time to tram your machine again.

Additionally, if you make any changes to your machine, such as replacing the spindle or the bed, you should plan to tram it again to ensure that everything is aligned properly.

Can I Tram My CNC Router Myself?

Yes, you can tram your CNC router yourself. However, it is important to follow the manufacturer’s instructions carefully and to use the right tools for the job. Using the wrong tools or making adjustments without knowing what you are doing can lead to costly mistakes and damage to your machine.

If you are not comfortable tramming your CNC router yourself, it is best to hire a professional to do it for you. This will ensure that the job is done correctly and that your machine is working as it should.

What Are Some Common Mistakes to Avoid When Tramming a CNC Router?

Some common mistakes to avoid when tramming a CNC router include using the wrong tools, not following the manufacturer’s instructions, and not taking accurate measurements. It is also important to make sure that your machine is level before you begin the tramming process.

Additionally, it is important to avoid making adjustments to your machine without knowing what you are doing. Making the wrong adjustments can lead to costly mistakes and damage to your machine.

In conclusion, learning how to tram a CNC router is an essential skill for any woodworker or hobbyist looking to achieve precise and accurate cuts. By following the steps outlined in this guide, you should be able to tram your router and ensure that it is level and perpendicular to the table.

Remember, the key to success is taking your time and being patient. Rushing through the process can result in an improperly trammed router, which can lead to inaccurate cuts and wasted materials.

So take your time, double-check your measurements, and don’t be afraid to ask for help if you need it. With practice and persistence, you’ll be able to tram your CNC router like a pro and achieve the precision and accuracy you need for your woodworking projects.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com