Table of Contents

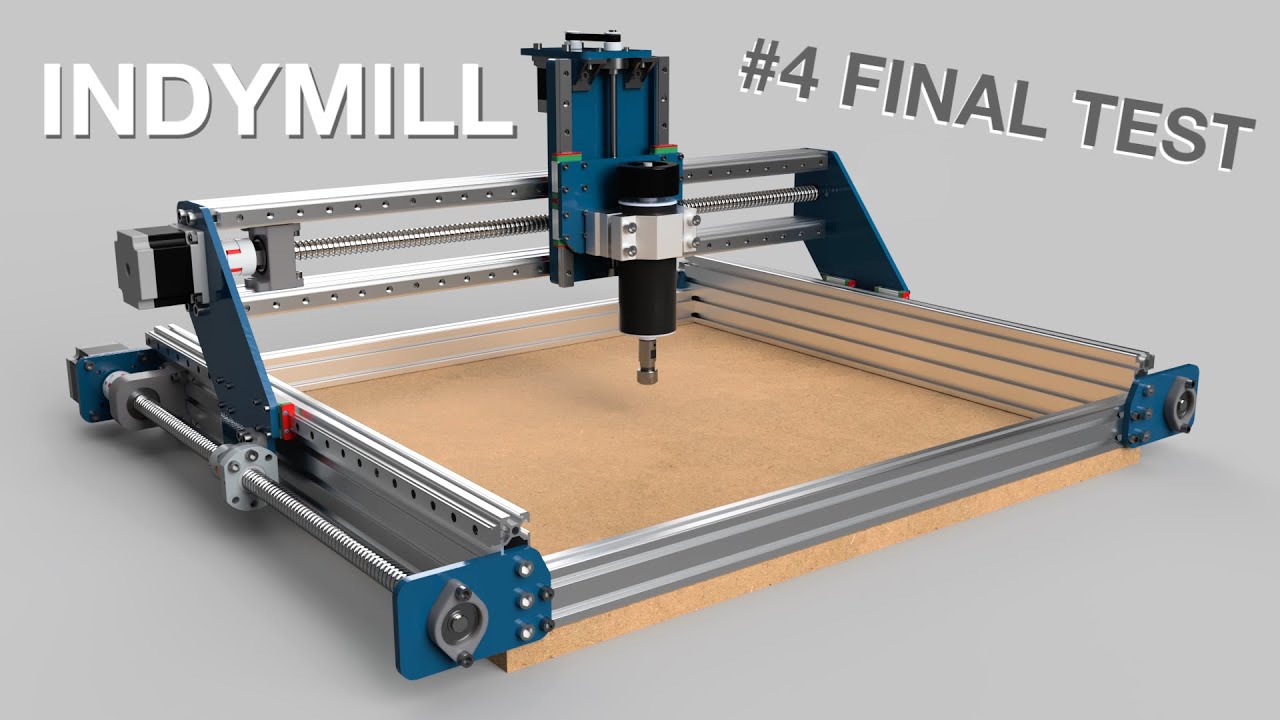

Have you ever wanted to make your own custom parts or designs? A hobby CNC machine may be just what you need! With this versatile tool, you can create intricate designs and shapes with ease.

But where do you start? How do you use a CNC machine? Don’t worry, we’ve got you covered. In this article, we’ll provide a step-by-step guide on how to use a hobby CNC machine, from choosing the right software to cutting your first piece. Let’s get started!

How to Use a Hobby CNC Machine?

- Choose your design: The first step is to choose a design you want to create. You can either create your own design or use an existing one.

- Prepare the material: Once you have your design, you need to prepare the material you will be using. This could be wood, plastic or metal.

- Set up the machine: Before using the CNC machine, you need to set it up. This involves installing the necessary software, connecting it to a computer, and ensuring everything is properly calibrated.

- Load the design: Once everything is set up, you can load your design onto the machine’s software. This will allow the machine to know what to create.

- Start the machine: After loading the design, you can start the machine. It will then begin to create your design automatically.

- Finishing touches: Once the machine has finished, you can remove your design and add any finishing touches that are required.

How to Use a Hobby CNC Machine?

If you’re looking to create intricate designs or parts with precision, a hobby CNC machine can be an excellent tool to have. CNC machines are computer-controlled machines that can cut, carve, or engrave various materials such as wood, plastic, or metal. In this article, we’ll be discussing how to use a hobby CNC machine.

Step 1: Choose Your Design

The first step in using a hobby CNC machine is to choose the design you want to create. This can be done by using computer-aided design (CAD) software, which allows you to create a digital model of your design. Once you have your design, you’ll need to convert it into a format that your CNC machine can read. This is typically done using CAM software, which takes your design and generates the toolpaths needed to create it.

Once you have your design and toolpaths ready, you’ll need to load them onto your CNC machine. This is typically done using a USB drive, although some machines may have other methods for loading files.

Step 2: Set Up Your Materials

Before you start cutting or carving, you’ll need to set up your materials. This involves securing your material to the bed of the CNC machine using clamps or other methods. It’s important to ensure that your material is level and secure, as any movement during the cutting process can result in errors.

You’ll also need to set your machine’s zero or home position. This is the point where your machine will start cutting or carving from. You’ll need to set this position based on the size and shape of your material, as well as the tool you’ll be using.

Step 3: Begin Cutting or Carving

Once your materials are set up and your machine is ready, it’s time to begin cutting or carving. This process is typically automated, with the machine following the toolpaths generated by your CAM software. However, it’s important to monitor the process to ensure that everything is going smoothly and to make any adjustments as needed.

During the cutting or carving process, your machine may generate dust or debris. It’s important to wear appropriate safety gear, such as a dust mask or safety glasses, to protect yourself from these hazards.

Step 4: Finishing Touches

Once your machine has finished cutting or carving, it’s time to remove your finished product from the bed of the CNC machine. You may need to sand or finish your product to achieve the desired final result. This is typically done using hand tools or other finishing methods.

Benefits of Using a Hobby CNC Machine

Using a hobby CNC machine can offer several benefits, including:

– Precision: CNC machines can create highly precise and accurate cuts or carvings, making them ideal for creating intricate designs or parts.

– Efficiency: CNC machines are typically much faster than manual methods, allowing you to create your designs in less time.

– Consistency: CNC machines can produce consistent results, ensuring that each product is the same as the last.

Hobby CNC Machine vs. Professional CNC Machine

While hobby CNC machines can offer many benefits, they do have some limitations compared to professional-grade machines. Some differences include:

– Size: Hobby CNC machines are typically smaller than professional machines, limiting the size of materials you can work with.

– Complexity: Professional machines may offer more complex cutting or carving options, allowing for more intricate designs.

– Price: Professional machines can be significantly more expensive than hobby machines, making them less accessible to hobbyists or smaller businesses.

Conclusion

Using a hobby CNC machine can be a rewarding experience, allowing you to create intricate designs or parts with precision and efficiency. By following the steps outlined in this article, you can get started with your own hobby CNC machine and begin creating your own designs.

Frequently Asked Questions

Here are some commonly asked questions about how to use a hobby CNC machine.

What is a hobby CNC machine?

A hobby CNC machine is a computer-controlled machine that can be used to cut and shape a variety of materials. These machines are typically smaller and less expensive than industrial CNC machines, making them a popular choice for hobbyists and small businesses.

Hobby CNC machines come in a variety of sizes and configurations, and can be used to cut materials such as wood, plastic, and metal. They are controlled by software that allows users to create designs and specify the cutting paths that the machine will follow.

What software do I need to use a hobby CNC machine?

To use a hobby CNC machine, you will need software that can create designs and generate toolpaths that the machine can follow. Some popular software options include Fusion 360, Vectric Aspire, and Carbide Create.

Once you have created your design, you will need to export it as a G-code file, which is a format that the CNC machine can understand. Many software programs have built-in tools for generating G-code, or you can use a separate program such as CAMotics or Universal Gcode Sender.

What materials can I cut with a hobby CNC machine?

Hobby CNC machines can be used to cut a wide variety of materials, including wood, plastic, metal, and even some types of stone. The type of material you can cut will depend on the size and power of your machine, as well as the type of cutting tool you are using.

When cutting materials with a hobby CNC machine, it is important to use the appropriate cutting tool and cutting parameters for the material you are working with. This will help ensure that you achieve the desired results and that your machine operates safely and efficiently.

How do I set up my hobby CNC machine?

Setting up a hobby CNC machine involves several steps, including assembling the machine, connecting it to your computer, and configuring the software. The exact steps will depend on the specific machine you are using, so it is important to refer to the manufacturer’s instructions.

In general, you will need to install any necessary drivers or software, connect the machine to your computer, and calibrate the machine to ensure that it is properly aligned and ready to cut. You will also need to set up the cutting tool and specify the cutting parameters for your project.

What are some tips for using a hobby CNC machine?

Here are a few tips for using a hobby CNC machine:

- Always wear appropriate safety gear, including eye protection and earplugs.

- Start with simple projects and work your way up to more complex designs.

- Take the time to calibrate your machine and set up your cutting parameters properly.

- Keep your cutting tools sharp and replace them as needed.

- Be patient and don’t rush the cutting process, as this can result in mistakes or damage to your machine.

By following these tips and taking the time to learn how to use your hobby CNC machine properly, you can create a wide variety of projects and achieve professional-quality results.

In conclusion, a hobby CNC machine is a fantastic tool that can provide hours of enjoyment and endless possibilities for creativity. Whether you are a hobbyist or a professional, learning how to use a CNC machine can greatly enhance your skills and abilities.

To get started, it is important to choose the right machine for your needs and budget. Look for one that is easy to use and comes with good software and support. Once you have your machine, take the time to learn how to use it properly and safely. Start with simple projects and gradually work your way up to more complex ones.

Finally, don’t be afraid to experiment and have fun with your hobby CNC machine. There are countless ways to use it, from creating unique gifts and decorations to making custom parts and prototypes. With a little practice and patience, you can become a skilled CNC machinist and enjoy the many benefits of this exciting hobby.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com