Table of Contents

Paragraph 1:

Are you looking to take your CNC lathe operations to the next level? If so, it’s time to master the use of G41 and G42. These codes are critical to the accuracy of the cutting tool and can help you achieve precision and efficiency in your work.

Paragraph 2:

But how do you use G41 and G42? Don’t worry, we’ve got you covered. In this guide, we’ll walk you through the basics of these essential codes, including what they are, how they work, and how to use them effectively in your CNC lathe operations. So, let’s get started!

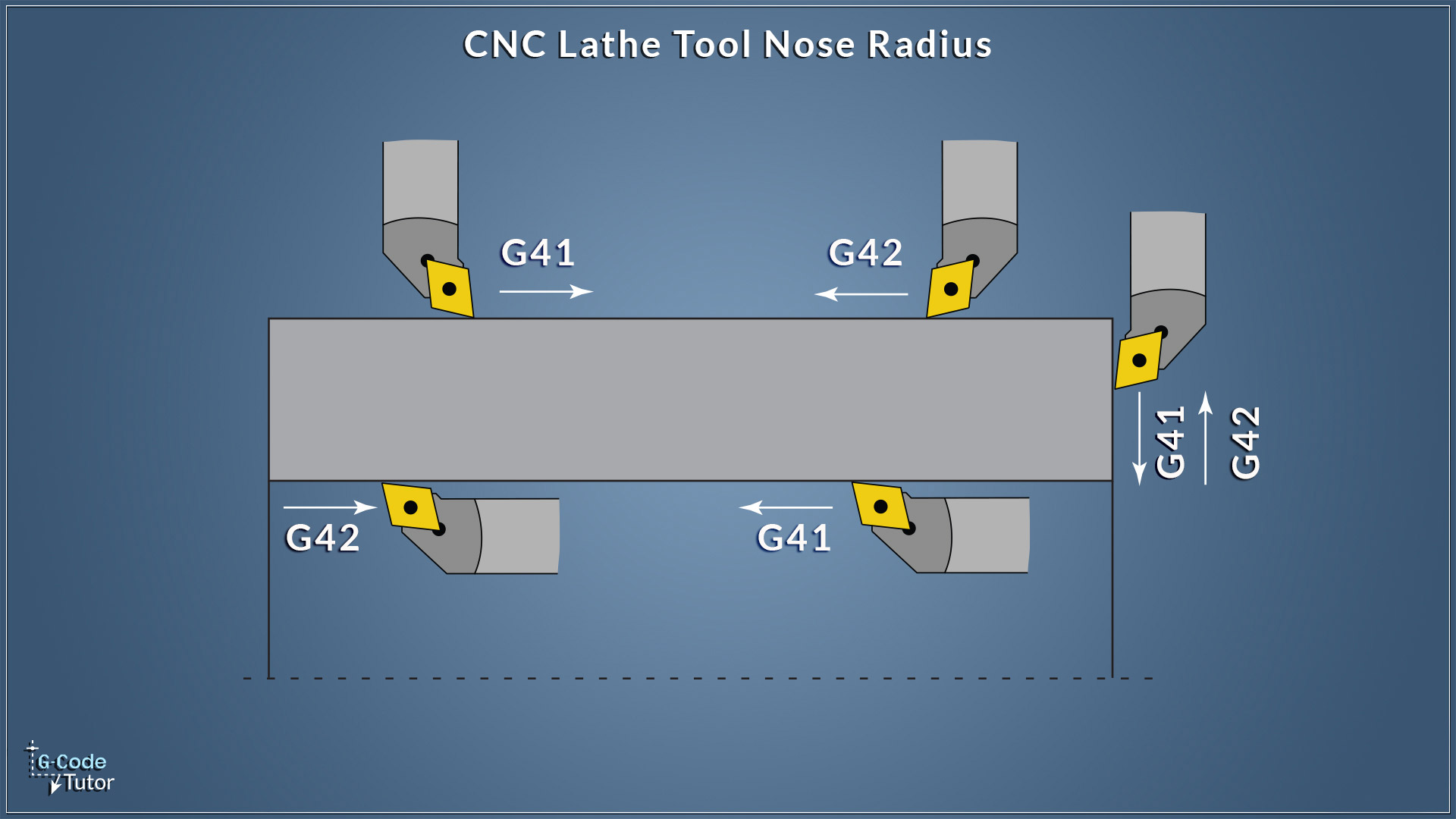

G41 and G42 are tool compensation codes used in CNC Lathe programming. G41 is used for left tool compensation, while G42 is used for right tool compensation. These codes are used to adjust the tool’s position to compensate for the tool’s radius, ensuring accurate cutting. To use G41 or G42, simply input the code followed by the tool’s radius value. For example, G41 X1.0 would set left tool compensation with a radius of 1.0. Make sure to cancel the code with G40 before using a different tool or changing the radius value.

How to Use G41 and G42 in CNC Lathe?

CNC lathe machines are used in various industries to produce high-quality products with precision and accuracy. G41 and G42 are two of the most commonly used codes in CNC lathe machining. These codes are used to compensate for the tool’s radius when cutting a part. In this article, we will discuss how to use G41 and G42 in CNC lathe machines.

What is G41 and G42?

G41 and G42 are the CNC lathe machine codes used for tool radius compensation. These codes help the machine to adjust the tool path based on the radius of the cutting tool. The cutting tool’s radius is measured from the center of the tool to the cutting edge. The G41 and G42 codes are used to compensate for the radius of the cutting tool so that the machine can produce precise and accurate parts.

When using G41, the CNC lathe machine will compensate for the tool’s radius to the left of the cutting path, while G42 will compensate for the tool’s radius to the right of the cutting path.

How to Use G41 and G42 in CNC Lathe?

To use G41 and G42 in CNC lathe machines, you need to follow the steps below:

Step 1: Load the program into the CNC lathe machine.

Step 2: Set the starting point for the program.

Step 3: Determine the radius of the cutting tool.

Step 4: Enter the G41 or G42 code in the program.

Step 5: Specify the compensation value.

Step 6: Start the machine.

Step 7: Monitor the machine and make any necessary adjustments.

Benefits of Using G41 and G42 in CNC Lathe

Using G41 and G42 codes in CNC lathe machines provides several benefits, including:

Improved accuracy: The tool radius compensation feature ensures that the machine produces precise and accurate parts.

Reduced setup time: The CNC lathe machine can automatically compensate for the tool’s radius, reducing the time required for manual adjustments.

Increased efficiency: With tool radius compensation, the machine can work faster and produce more parts in less time.

G41 vs G42

G41 and G42 are similar codes used for tool radius compensation. The primary difference between the two codes is their direction of compensation. G41 compensates for the tool’s radius to the left of the cutting path, while G42 compensates for the tool’s radius to the right of the cutting path.

Both codes have their specific uses, depending on the part’s design and the cutting tool’s position. It is essential to understand the differences between these codes and use them appropriately to produce accurate and precise parts.

Conclusion

G41 and G42 are essential codes in CNC lathe machining, used for tool radius compensation. These codes help the machine to produce precise and accurate parts by compensating for the tool’s radius. By understanding how to use G41 and G42 and their benefits, you can improve your CNC lathe machining efficiency and produce high-quality products.

Frequently Asked Questions

In this section, we will answer some of the commonly asked questions about using G41 and G42 in CNC lathe.

What is G41 and G42 in CNC Lathe?

G41 and G42 are cutter compensation codes used in CNC lathe to offset the tool’s position. G41 is used for left-hand cutting tools, while G42 is used for right-hand cutting tools. When these codes are used, the machine’s software automatically adjusts the tool’s position to compensate for the tool’s radius.

These codes are essential in CNC lathe operations because they help to improve the accuracy and precision of the finished product. They are particularly useful when working with complex geometries or when making multiple passes with the same tool.

How do I use G41 and G42 in CNC Lathe?

To use G41 or G42 in CNC lathe, you need to include the code in your program. The code is typically included in the same block of code as the G-code command that specifies the tool’s position.

For example, to use G41 with a left-hand cutting tool, you would include the following code: G41 X__ Z__. The X and Z values are the coordinates that specify the tool’s position. The machine’s software will automatically adjust the tool’s position based on the tool’s radius.

What are the advantages of using G41 and G42 in CNC Lathe?

The main advantage of using G41 and G42 in CNC lathe is that they help to improve the accuracy and precision of the finished product. By compensating for the tool’s radius, these codes ensure that the tool always cuts at the correct position.

Another advantage of using these codes is that they simplify the programming process. Instead of manually adjusting the tool’s position for every pass, the machine’s software does it automatically. This can save a lot of time and reduce the likelihood of errors.

What are the limitations of using G41 and G42 in CNC Lathe?

One limitation of using G41 and G42 in CNC lathe is that they only work with cutting tools that have a constant radius. If the tool’s radius changes, the compensation will be incorrect, leading to inaccuracies in the finished product.

Another limitation of using these codes is that they can be complex to use, particularly for beginners. It’s essential to have a good understanding of the tool’s radius and how the software compensates for it to use these codes effectively.

How do I troubleshoot issues with G41 and G42 in CNC Lathe?

If you are experiencing issues with G41 and G42 in CNC lathe, the first step is to check your program for errors. Ensure that the code is correctly formatted and that the tool’s position is specified correctly.

If you are still experiencing issues, you may need to adjust the tool’s radius or check your machine’s settings. It’s also a good idea to consult with the machine’s manual or contact the manufacturer for assistance.

In conclusion, G41 and G42 are essential codes for CNC lathe operators. G41 is used to compensate for the tool’s diameter, while G42 compensates for the tool’s radius. These codes ensure precision and accuracy in the machining process, resulting in high-quality products.

To use G41 and G42, the operator must input the correct values for the tool’s diameter or radius. It is important to note that these values vary depending on the tool used and the material being machined. Therefore, proper measurement and calculation are necessary to ensure the correct input.

In summary, mastering G41 and G42 is crucial for CNC lathe operators to produce precise and accurate products. By understanding the codes’ functions and inputting accurate values, operators can achieve optimal machining results and meet their customers’ demands for high-quality products.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com