Table of Contents

As a CNC machine operator, you know how important it is to have your machine up and running at optimal levels. However, before you can dive into the production process, it’s essential to warm up your CNC machine properly. Warming up your machine can help to increase its lifespan and improve its overall performance.

In this article, we’ll discuss why warming up your CNC machine is important, the steps you should take to warm up your machine, and some tips to ensure that your machine is running at its best. Whether you’re a seasoned CNC machine operator or just starting, this article is for you. So, let’s dive in!

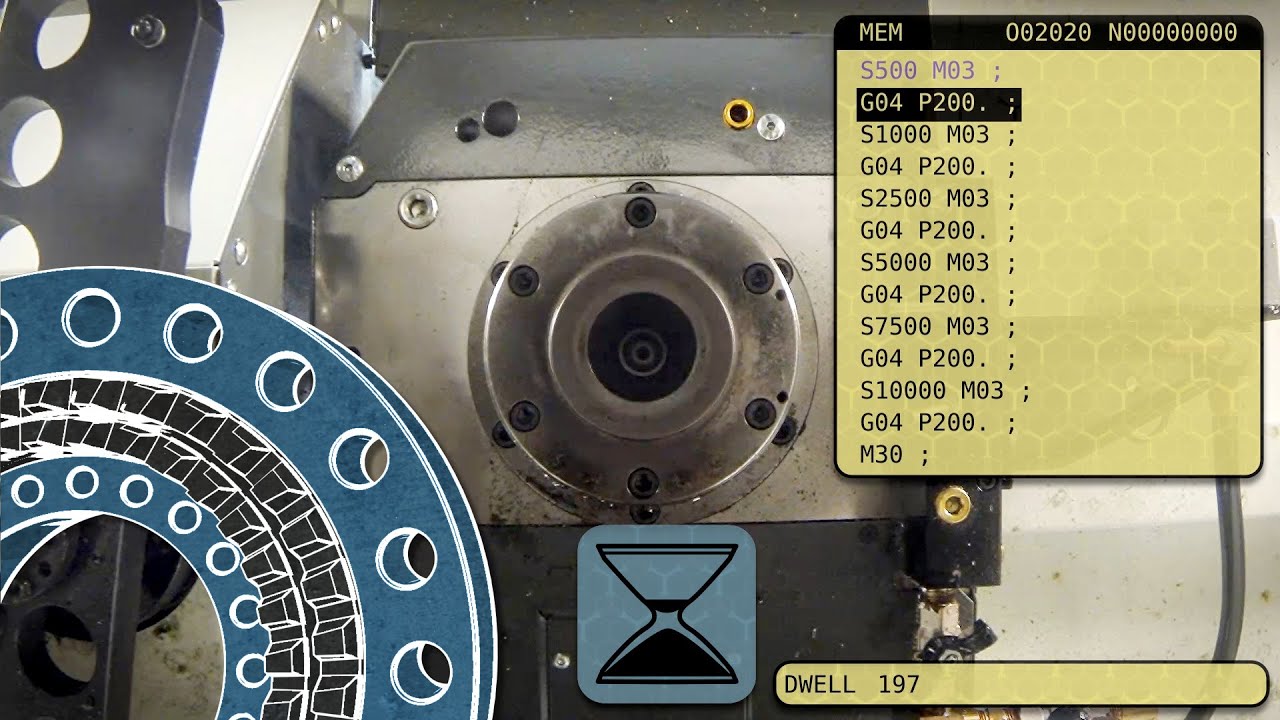

To warm up your CNC machine, follow these steps:

- Turn on the machine and let it run idle for 5-10 minutes to allow the components to reach their operating temperature.

- Next, run a test program to check the machine’s accuracy and ensure everything is working correctly.

- Finally, adjust the machine’s settings as needed before starting your production run.

Warming up your CNC machine is essential to ensure accurate and efficient performance. By following these steps, you can help prevent errors and ensure a successful production run.

How to Warm Up Your CNC Machine?

Warming up your CNC machine is essential to ensure optimal performance and accurate cuts. In this article, we will discuss the importance of warming up your CNC machine and provide you with step-by-step instructions on how to warm up your machine properly.

Why is Warming Up Your CNC Machine Important?

Warming up your CNC machine before use is crucial for several reasons. First, it allows the machine to reach its optimal operating temperature, which ensures that all the components are working correctly. Second, it helps to reduce the risk of thermal expansion, which can cause inaccuracies in your cuts. Finally, warming up your machine can help extend its lifespan by reducing wear and tear on the components.

To warm up your CNC machine, follow these steps:

- Turn on the machine and let it warm up for at least 10-15 minutes.

- Check the temperature of the spindle, motor, and other critical components using a thermometer or infrared temperature gun.

- If the temperature is not within the recommended range, continue to let the machine warm up until it reaches the optimal temperature.

- Once the machine has reached the optimal temperature, perform a test cut to ensure that the machine is working correctly.

Benefits of Warming Up Your CNC Machine

There are several benefits to warming up your CNC machine properly. These include:

- Improved accuracy in your cuts

- Reduced risk of thermal expansion

- Extended lifespan of your machine

- Reduced wear and tear on the components

- Elimination of any condensation that may have accumulated during storage

Warming Up Your CNC Machine vs. Not Warming it up

Warming up your CNC machine is essential to ensure optimal performance and accuracy. If you do not warm up your machine properly, you run the risk of thermal expansion, which can cause inaccuracies in your cuts. Additionally, not warming up your machine can lead to increased wear and tear on the components, which can reduce the lifespan of your machine.

Overall, warming up your CNC machine is a quick and easy process that can have significant benefits for your machine’s performance and lifespan. By following the steps outlined in this article, you can ensure that your machine is always working at its best.

Frequently Asked Questions

What is the importance of warming up a CNC machine?

Warming up a CNC (Computer Numerical Control) machine is essential before starting any operation. It helps to stabilize the machine’s temperature, reducing thermal expansion, and ensuring dimensional accuracy. Not warming up the machine can lead to errors in the manufacturing process, which may result in wasted materials, increased downtime, and decreased productivity.

To warm up a CNC machine, start by turning on the power and allowing the machine to sit idle for 10-15 minutes. This will allow the machine’s components to reach a stable temperature. Afterward, run a program with low cutting speeds and feeds to allow the machine to warm up further.

How long should a CNC machine be warmed up?

The length of time required to warm up a CNC machine depends on the machine’s size, complexity, and the surrounding environment. However, as a general rule, it is recommended to warm up the machine for at least 30 minutes before starting any operation. This will allow the machine to reach a stable temperature, reducing thermal expansion, and ensuring dimensional accuracy.

It is essential to note that not warming up the machine for the recommended time can have a significant impact on the quality of the finished product, as well as the lifespan of the machine.

Can I skip the warm-up process?

Skipping the warm-up process can have severe consequences on the manufacturing process. Failing to warm up the machine can lead to errors in the manufacturing process, which may result in wasted materials, increased downtime, and decreased productivity. Moreover, not warming up the machine can cause thermal expansion, leading to inaccurate dimensions and poor surface finishes.

Therefore, it is crucial to warm up the machine before starting any operation, as this will improve the quality of the finished product and prolong the life of the machine.

What should I do if my CNC machine overheats?

CNC machines can overheat due to various reasons, including high ambient temperature, prolonged use, and lack of maintenance. If you notice that your CNC machine is overheating, the first thing you should do is turn off the machine and wait for it to cool down. This will help prevent any further damage to the machine’s components.

After the machine has cooled down, check the coolant level and ensure that it is sufficient. Also, make sure that the machine’s air vents are not blocked, as this can cause the machine to overheat. If the problem persists, contact a qualified technician to inspect the machine and identify the underlying issue.

What are the benefits of warming up a CNC machine?

Warming up a CNC machine has several benefits, including improving the quality of the finished product, reducing thermal expansion, and prolonging the life of the machine. Warming up the machine also helps to stabilize the machine’s temperature, reducing the risk of errors in the manufacturing process.

Moreover, warming up the machine before starting any operation can help reduce downtime, increase productivity, and save on materials and energy costs. Therefore, it is essential to warm up the machine before starting any operation to reap these benefits.

In conclusion, warming up a CNC machine is a crucial step to ensure optimal performance and longevity of the machine. By following the necessary steps, you can avoid potential errors and minimize downtime during the machining process.

Remember to always check the coolant level and ensure it’s at the appropriate temperature before starting the machine. Additionally, pay attention to any unusual sounds or vibrations that may indicate a problem with the machine.

Lastly, don’t rush the warm-up process. Allow enough time for the machine to reach its operating temperature before beginning any machining operations. Taking these precautions can help you achieve high-quality results and prevent costly repairs down the line.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com