Table of Contents

Introduction:

CNC lathes have revolutionized the machining industry by automating the manufacturing process. However, to operate a CNC lathe, one needs to know how to write a program. This can be a daunting task for beginners, but with the right guidance, anyone can learn how to write a CNC lathe program.

In this article, we will provide a step-by-step guide on how to write a CNC lathe program. We will cover the basics of G-code, the language used to program CNC machines, and provide examples to help you understand the process. By the end of this article, you will have the knowledge and confidence to write your own CNC lathe programs and take your machining skills to the next level. So, let’s get started!

- Choose a CAM software that is compatible with your CNC lathe.

- Create a new project and select the CNC lathe machine type.

- Import or create a 3D CAD model of your part.

- Define the cutting tools you will use and their respective parameters.

- Create tool paths by selecting the geometry to be machined and specifying machining parameters such as cutting speed, feed rate, and depth of cut.

- Simulate the program to ensure it runs correctly and avoid costly mistakes.

- Post-process the program to generate machine-specific G-code that can be loaded into the CNC lathe controller.

How to Write a CNC Lathe Program?

CNC lathe programming is an essential skill for anyone who wants to succeed in the manufacturing industry. It involves using computer-aided software to control the movements of a lathe machine, which is used to shape and cut materials to precise specifications. In this article, we’ll provide a step-by-step guide on how to write a CNC lathe program, from set up to execution.

Step 1: Understand the Basics of CNC Lathe Programming

Before you start writing a CNC lathe program, it’s important to understand the basics of the process. A CNC lathe machine is a computer-controlled machine that uses a cutting tool to remove material from a rotating workpiece. The program that controls the movements of the machine is written in G-code, a programming language that is used to control the movements of CNC machines.

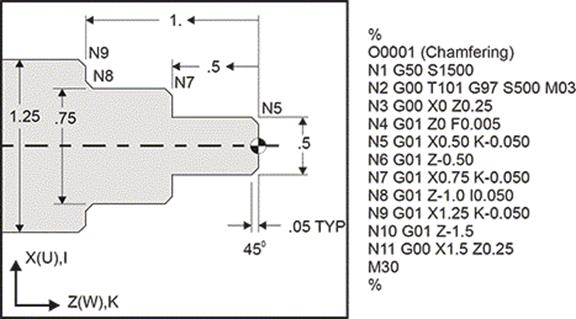

To write a CNC lathe program, you need to understand the basic commands of G-code, such as G00 for rapid movement, G01 for linear movement, and G02/G03 for circular movement. You also need to understand the different types of tooling available for the lathe machine, such as turning tools and boring tools.

Once you have a basic understanding of these concepts, you can start writing your program.

Step 2: Set Up Your CNC Lathe Machine

Before you write your program, you need to set up your CNC lathe machine. This involves mounting the workpiece onto the spindle and selecting the appropriate cutting tool for the job. You also need to set the spindle speed and feed rate, which will determine how fast the machine rotates and how quickly the cutting tool moves.

Most CNC lathe machines come with software that allows you to input these settings manually, or you can use pre-set values for common materials and cutting tools.

Step 3: Write Your CNC Lathe Program

Once your machine is set up, you can start writing your CNC lathe program. This involves using G-code commands to control the movements of the machine and the cutting tool. You can either write the program manually, using a text editor, or you can use a computer-aided manufacturing (CAM) software to generate the code automatically.

When writing your program, make sure to include all the necessary G-code commands, such as spindle speed, feed rate, and tool selection. You should also include details about the size and shape of the workpiece, as well as any specific cutting or shaping instructions.

Step 4: Test Your CNC Lathe Program

Before you execute your CNC lathe program, it’s important to test it to make sure it works as intended. You can do this by running the program in simulation mode, which allows you to see how the machine will move and cut the workpiece without actually executing the program.

If everything looks good in simulation mode, you can then execute the program on the machine.

Step 5: Monitor Your CNC Lathe Machine

Once your program is running, it’s important to monitor your CNC lathe machine to make sure everything is working properly. This includes checking the spindle speed and feed rate, as well as watching for any signs of tool wear or damage.

You should also keep an eye on the workpiece to make sure it’s being cut and shaped to the correct specifications.

Step 6: Make Adjustments as Needed

If you notice any issues with your CNC lathe program or machine, you may need to make adjustments to the program or the machine settings. This could include changing the cutting tool or adjusting the spindle speed or feed rate.

It’s important to make these adjustments carefully and systematically, testing the program after each change to make sure it’s working correctly.

Step 7: Troubleshoot Common Issues

Even with careful planning and execution, there may be times when you encounter issues with your CNC lathe program or machine. Common issues include tool wear, material deformation, and machine malfunctions.

To troubleshoot these issues, you can refer to the machine manual or seek assistance from a qualified technician.

Step 8: Save Your CNC Lathe Program

Once your program is complete and tested, it’s important to save it for future use. You can do this by storing the G-code on a USB drive or other storage device, or by saving it to the machine’s internal memory.

It’s also a good idea to back up your program regularly, in case of data loss or machine malfunction.

Step 9: Benefits of CNC Lathe Programming

CNC lathe programming offers a number of benefits over traditional manual machining. For one, it allows for much greater precision and accuracy, as the computer-controlled movements of the machine are far more consistent than those of a human operator.

CNC lathe programming also allows for faster and more efficient machining, as multiple tooling operations can be performed in a single program. This reduces the amount of time and labor required to complete a job, while also increasing the overall quality of the finished product.

Step 10: CNC Lathe Programming vs. Manual Machining

While CNC lathe programming offers many advantages over manual machining, there are still some situations where manual machining may be preferable. For example, if you’re working with a small batch of parts or a particularly complex shape, manual machining may be more cost-effective and efficient.

However, for larger production runs or simpler shapes, CNC lathe programming is almost always the better choice. It offers greater precision, efficiency, and consistency, leading to higher-quality products and greater overall productivity.

In conclusion, CNC lathe programming is an essential skill for anyone in the manufacturing industry. By following these steps and guidelines, you can learn how to write a CNC lathe program that will allow you to create high-quality parts and products with greater precision and efficiency.

Frequently Asked Questions

Here are some common questions and answers about how to write a CNC lathe program.

What is a CNC lathe program?

A CNC lathe program is a set of instructions that tells a CNC lathe machine how to cut and shape a piece of material. The program is created using a computer-aided manufacturing (CAM) software, which generates the toolpath and converts it into a language that the CNC machine can understand. The program includes information about the cutting tools, spindle speed, feed rate, and other variables that affect the machining process.

To create a CNC lathe program, you need to have a good understanding of the machining process, as well as the software and hardware used in CNC machining. You also need to be able to read and interpret technical drawings and specifications, and be familiar with programming languages such as G-code and M-code.

What are the basic steps for writing a CNC lathe program?

The basic steps for writing a CNC lathe program are as follows:

1. Create a technical drawing or CAD model of the part you want to machine.

2. Use CAM software to generate the toolpath and create the CNC program.

3. Choose the cutting tools and set the machining parameters, such as the spindle speed and feed rate.

4. Test the program using simulation software to ensure that the toolpath is correct and the machining process will produce the desired result.

5. Transfer the program to the CNC machine and run the machining process.

What are some best practices for writing a CNC lathe program?

Here are some best practices for writing a CNC lathe program:

1. Always start with a clear and detailed technical drawing or CAD model of the part you want to machine.

2. Use CAM software to generate the toolpath and create the CNC program, rather than writing the program manually.

3. Choose the cutting tools and set the machining parameters carefully, based on the material properties and the desired result.

4. Test the program using simulation software to ensure that the toolpath is correct and the machining process will produce the desired result.

5. Document the program carefully, including the toolpath, cutting tools, and machining parameters, so that it can be easily modified or reused in the future.

What are some common mistakes to avoid when writing a CNC lathe program?

Here are some common mistakes to avoid when writing a CNC lathe program:

1. Starting with an incomplete or inaccurate technical drawing or CAD model.

2. Using inappropriate or poorly maintained cutting tools.

3. Setting incorrect machining parameters, such as the spindle speed or feed rate.

4. Failing to test the program using simulation software, and discovering errors or mistakes during the actual machining process.

5. Failing to document the program properly, making it difficult to modify or reuse in the future.

How can I learn more about writing CNC lathe programs?

There are many resources available for learning how to write CNC lathe programs, including online tutorials, courses, and books. You can also attend training programs offered by CNC machine manufacturers or CNC software vendors. It is important to gain experience by practicing on a CNC machine and experimenting with different cutting tools and machining parameters. Networking with other CNC programmers and machinists can also be helpful for learning new techniques and best practices.

In conclusion, writing a CNC lathe program requires knowledge and attention to detail. It is a skill that takes time and practice to master, but with the right training and resources, anyone can learn how to create efficient and precise programs for a CNC lathe.

As you embark on your journey to become a proficient CNC lathe programmer, remember to always start with a clear understanding of the machine and the materials you will be working with. Take the time to carefully plan out your program, considering factors such as tool selection and cutting paths. And finally, don’t be afraid to seek out help and resources when needed, whether it be from an experienced colleague or online tutorials.

With these tips in mind, you can confidently tackle the task of writing a CNC lathe program and produce high-quality, accurate parts every time. So, roll up your sleeves and get ready to dive into the world of CNC programming – the possibilities are endless!

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com