Table of Contents

Are you curious about the difference between a CNC machine and a robot? Many people use the terms interchangeably, but there are distinct differences between the two. While a CNC machine and a robot may seem similar at first glance, understanding their unique characteristics is essential in determining their functions and applications.

A CNC machine is a computer-controlled machine tool that can perform a variety of manufacturing tasks with precision and accuracy. On the other hand, a robot is an automated machine that can be programmed to perform tasks that require human-like dexterity and decision-making. In this article, we will explore the differences between a CNC machine and a robot and answer the question; Is a CNC machine a robot?

No, a CNC machine is not a robot. While CNC machines are automated and can perform tasks that would otherwise require human intervention, they lack the ability to make decisions on their own or adapt to changing situations. Robots, on the other hand, are designed to work in dynamic environments and can adapt to new situations using sensors and algorithms. While similar in some ways, CNC machines and robots serve different purposes and are used in different industries.

H2: Is a CNC Machine a Robot?

When it comes to manufacturing, there are many different types of machines that are used to automate the process. Two of the most commonly used machines are CNC machines and robots. While they may seem similar, there are some key differences that set them apart. In this article, we’ll take a closer look at CNC machines and robots to determine whether or not a CNC machine can be considered a robot.

H3: What is a CNC Machine?

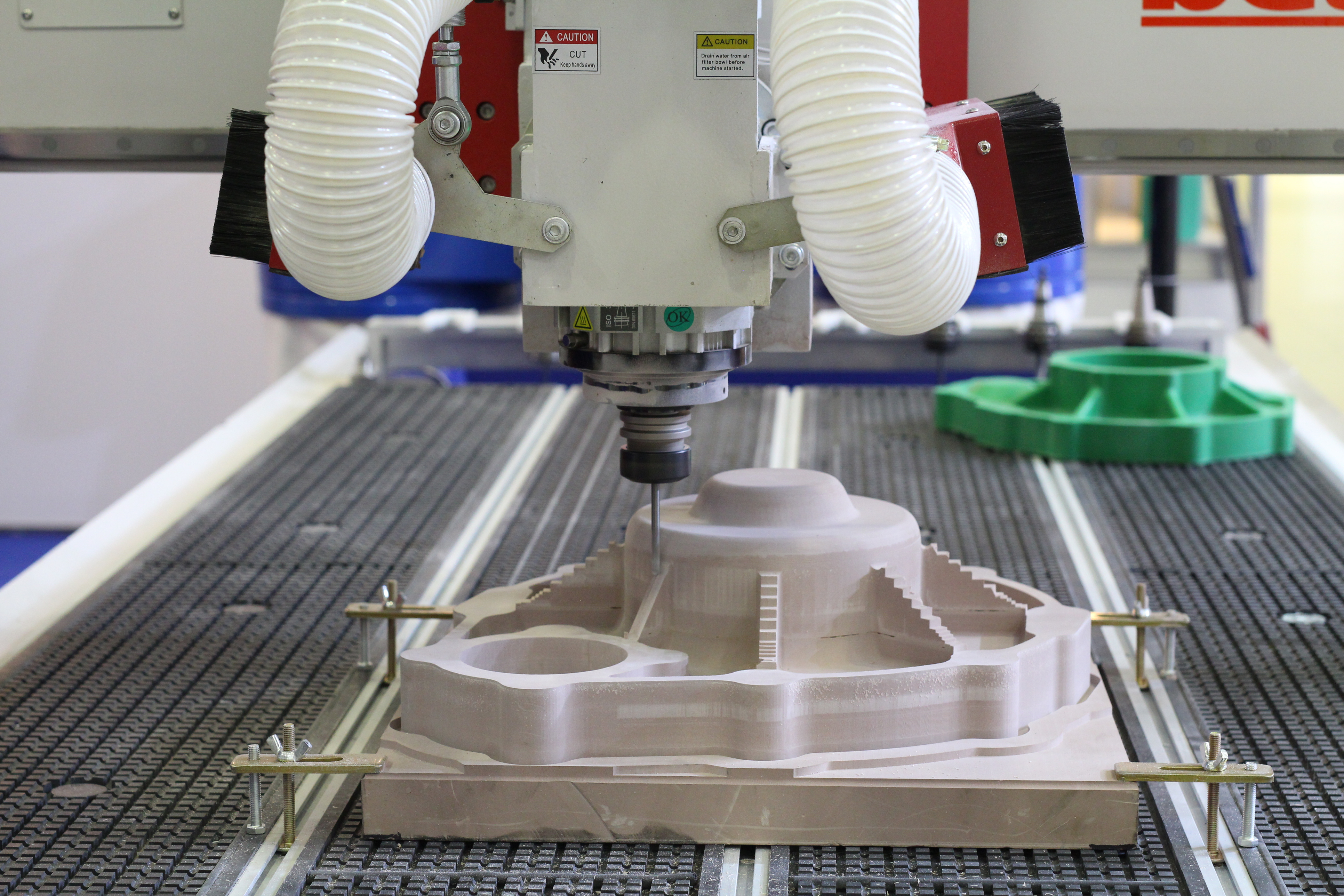

A CNC (Computer Numerical Control) machine is a type of machine tool that is used to automate the manufacturing process. They are typically used in industries such as aerospace, automotive, and medical device manufacturing. A CNC machine is controlled by a computer program that is able to precisely control the movement of the machine’s cutting tools. This allows for highly accurate and repeatable manufacturing processes.

There are many different types of CNC machines, including mills, lathes, routers, and grinders. Each type of machine is designed for a specific manufacturing process and is able to perform a wide range of operations with a high degree of precision.

H3: What is a Robot?

A robot is a machine that is able to perform a variety of tasks autonomously or under the control of a human operator. Robots are typically used in industries such as manufacturing, healthcare, and logistics. They can be programmed to perform a wide range of tasks, from simple repetitive tasks to complex operations that require a high degree of precision.

There are many different types of robots, including industrial robots, service robots, and medical robots. Each type of robot is designed for a specific purpose and is able to perform a wide range of tasks with a high degree of accuracy and efficiency.

H3: What are the Differences Between CNC Machines and Robots?

While CNC machines and robots may seem similar, there are some key differences that set them apart. The main difference is that CNC machines are designed to perform a specific manufacturing process, while robots are designed to perform a wide range of tasks.

CNC machines are typically used in industries such as aerospace, automotive, and medical device manufacturing. They are able to perform a wide range of operations with a high degree of precision, but they are limited to the specific manufacturing process for which they are designed.

Robots, on the other hand, are able to perform a wide range of tasks, from simple repetitive tasks to complex operations that require a high degree of precision. They are used in industries such as manufacturing, healthcare, and logistics, and they are able to adapt to a wide range of tasks with the use of specialized end-effectors and programming.

Another key difference between CNC machines and robots is the level of autonomy. CNC machines are typically controlled by a computer program, but they still require human intervention to set up and operate. Robots, on the other hand, can be programmed to operate autonomously, with little or no human intervention required.

H3: Benefits of Using CNC Machines

There are many benefits to using CNC machines in the manufacturing process. Some of the key benefits include:

– Precision: CNC machines are able to perform highly accurate and repeatable manufacturing processes, which leads to a higher quality end product.

– Efficiency: CNC machines are able to perform operations more quickly and efficiently than manual processes, which can help to reduce manufacturing time and costs.

– Flexibility: CNC machines are able to perform a wide range of operations, which makes them ideal for use in a variety of manufacturing processes.

– Safety: CNC machines are able to perform dangerous operations without putting human operators at risk.

H3: Benefits of Using Robots

There are also many benefits to using robots in the manufacturing process. Some of the key benefits include:

– Efficiency: Robots are able to perform tasks more quickly and efficiently than human operators, which can help to reduce manufacturing time and costs.

– Precision: Robots are able to perform highly accurate and repeatable manufacturing processes, which leads to a higher quality end product.

– Flexibility: Robots are able to adapt to a wide range of tasks, which makes them ideal for use in a variety of manufacturing processes.

– Safety: Robots are able to perform dangerous operations without putting human operators at risk.

H3: CNC Machines vs Robots: Which is Better?

When it comes to choosing between CNC machines and robots, there is no clear winner. Both types of machines have their own unique advantages and disadvantages, and the choice ultimately depends on the specific needs of the manufacturing process.

CNC machines are ideal for use in manufacturing processes that require a high degree of precision and repeatability. They are also ideal for use in industries that require a specific manufacturing process, such as aerospace or medical device manufacturing.

Robots, on the other hand, are ideal for use in manufacturing processes that require a high degree of flexibility and adaptability. They are able to perform a wide range of tasks and are ideal for use in industries such as automotive or logistics.

In conclusion, while CNC machines and robots may seem similar, there are some key differences that set them apart. While CNC machines are designed to perform a specific manufacturing process, robots are designed to perform a wide range of tasks. Both types of machines have their own unique advantages and disadvantages, and the choice ultimately depends on the specific needs of the manufacturing process.

Frequently Asked Questions

Here are some common questions about CNC machines and robots.

Is a CNC machine a robot?

This is a common question, and the answer is not straightforward. While a CNC machine and a robot share many similarities, they are not the same thing. A CNC machine is a computer-controlled machine tool that can perform a variety of tasks, such as cutting or drilling. It follows a pre-programmed set of instructions to perform these tasks.

A robot, on the other hand, is a machine that can be programmed to perform a variety of tasks. It can be programmed to move, manipulate objects, and perform tasks that require dexterity. While some CNC machines can perform tasks that are similar to those of a robot, they do not have the same level of flexibility and adaptability.

What are the main differences between a CNC machine and a robot?

The main differences between a CNC machine and a robot are their level of flexibility and adaptability. CNC machines are designed to perform specific tasks, and they are programmed to do so. They are not able to adapt to changes in their environment or perform tasks that are outside of their programming.

Robots, on the other hand, are designed to be more flexible and adaptable. They can be programmed to perform a variety of tasks, and they can adapt to changes in their environment. They also have the ability to learn from their surroundings and make decisions based on that information.

Can a CNC machine be converted into a robot?

In some cases, it may be possible to convert a CNC machine into a robot. This would require adding additional hardware and software to the machine to give it the ability to move and manipulate objects. However, this process can be complex and may not be cost-effective in all cases.

Additionally, even if a CNC machine is converted into a robot, it may not have the same level of flexibility and adaptability as a dedicated robot. It may still be limited in the tasks it can perform and the environments it can operate in.

What are some advantages of using a robot instead of a CNC machine?

There are several advantages to using a robot instead of a CNC machine. One of the main advantages is increased flexibility and adaptability. Robots can be programmed to perform a variety of tasks, and they can adapt to changes in their environment. They also have the ability to learn from their surroundings and make decisions based on that information.

Another advantage of using a robot is increased efficiency. Robots can work faster and more accurately than humans, which can lead to increased productivity and reduced costs. They can also work in environments that may be hazardous or uncomfortable for humans, such as high-temperature environments or areas with high levels of radiation.

Can a robot replace a CNC machine?

In some cases, a robot may be able to replace a CNC machine. This would depend on the specific tasks that need to be performed and the level of flexibility and adaptability required. If the tasks are relatively simple and do not require a high level of flexibility, a CNC machine may be more cost-effective.

However, if the tasks require a high level of flexibility and adaptability, a robot may be a better choice. Robots can be programmed to perform a variety of tasks and can adapt to changes in their environment. They can also work faster and more accurately than humans or CNC machines, which can lead to increased productivity and reduced costs.

In conclusion, the answer to whether a CNC machine is a robot is a bit complicated. While CNC machines are capable of performing tasks autonomously and can be programmed to follow specific instructions, they lack some of the key characteristics of a robot.

A robot typically has sensors that allow it to perceive and respond to its environment, while a CNC machine relies solely on its programmed instructions. Additionally, robots are designed to be versatile and adaptable, while CNC machines are typically designed for specific tasks.

However, as technology continues to advance, the line between CNC machines and robots may become increasingly blurred. Some CNC machines are already incorporating robotic technology, such as the ability to detect and correct errors in real-time. As such, it’s possible that in the future, the distinction between CNC machines and robots may become less clear-cut.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com