Table of Contents

In the world of manufacturing, efficiency and precision are key factors in determining the success of a business. With advancements in technology, there are now various machines that can help achieve these goals, including CNC machines and die cutters. However, many are left wondering which one is better. Is a CNC machine really superior to a die cutter? Let’s dive into the details and find out.

CNC machines and die cutters are both used to cut materials into specific shapes and sizes. While they may seem similar at first glance, there are notable differences between the two. In this article, we will compare and contrast the features of each machine, and ultimately determine which one is the better option for your business needs.

Both CNC machines and die cutters have their own set of advantages and disadvantages. CNC machines are great for complex designs and can work with a variety of materials. However, they are more expensive and require more maintenance. Die cutters, on the other hand, are more affordable and require less maintenance. They are best suited for simple designs and can only work with certain materials. Ultimately, the choice between the two depends on your specific needs and budget.

Is a CNC Machine Better Than a Die Cutter?

When it comes to cutting materials for manufacturing or crafting, there are two primary methods: using a CNC (Computer Numerical Control) machine or a die cutter. Both tools have their pros and cons, but which one is better? In this article, we’ll take a closer look at the differences between these two methods and explore which one might be a better fit for your needs.

What is a CNC Machine?

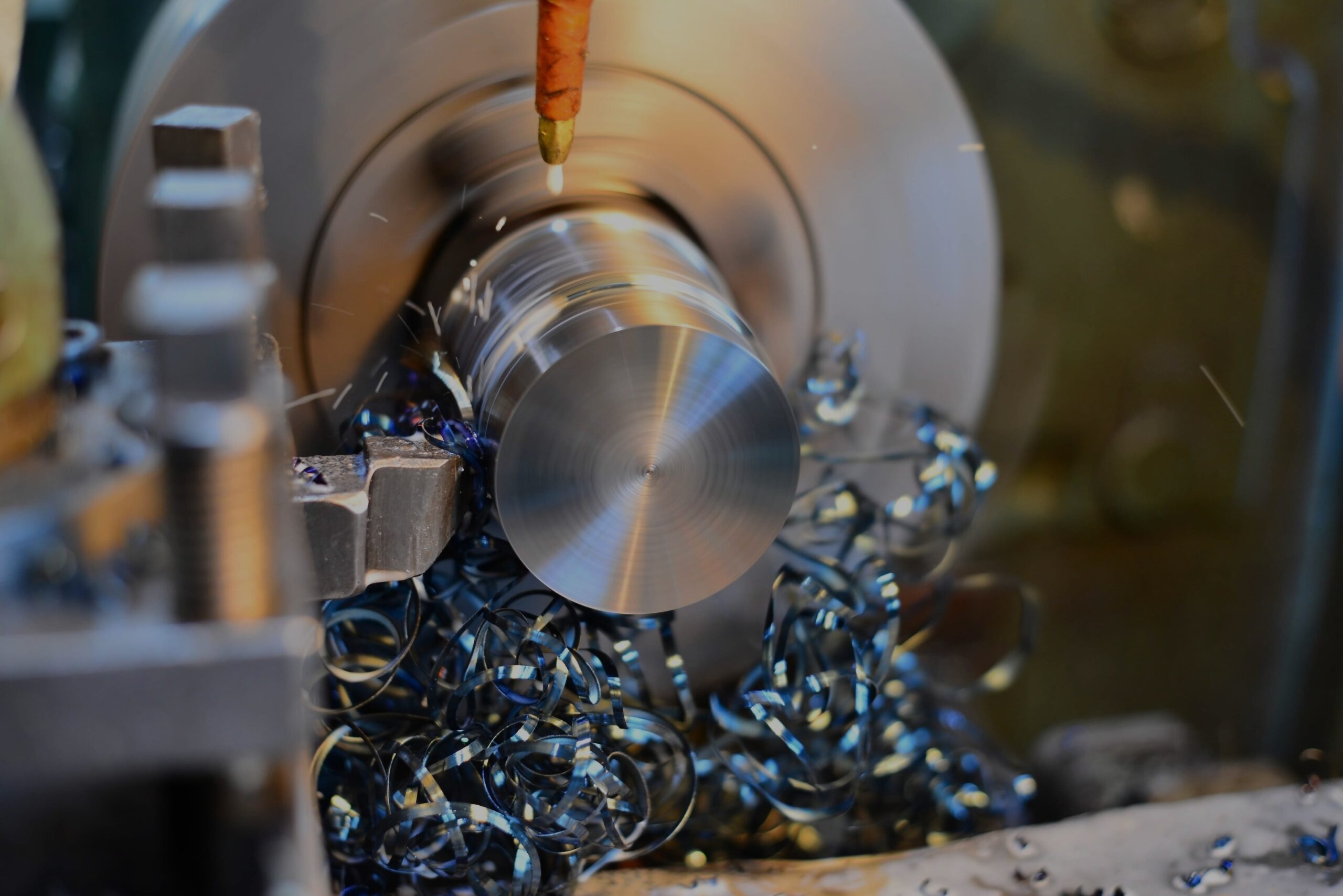

A CNC machine is a computer-controlled tool that uses a rotating cutting tool to cut and shape a variety of materials, including wood, metal, and plastics. The computer program controls the movements of the cutting tool, allowing for precise and accurate cuts. CNC machines can be used for a wide range of applications, from creating intricate shapes for jewelry to cutting precision parts for aerospace engineering.

One of the benefits of using a CNC machine is its versatility. CNC machines can be programmed to create a wide range of shapes and sizes, allowing for greater flexibility in manufacturing or crafting. Additionally, because the tool is computer-controlled, it can produce consistent results with a high degree of accuracy.

What is a Die Cutter?

A die cutter, on the other hand, is a mechanical tool that uses a metal die to cut materials. The die is a pre-made shape that is used to cut the material into specific shapes and sizes. Die cutters are commonly used for cutting paper, cardboard, and other thin materials.

While die cutters are limited in the shapes and sizes they can produce, they do offer some benefits. For one, they are generally less expensive than CNC machines. Additionally, because they are mechanical tools, they don’t require electricity or a computer program to operate.

CNC Machine vs. Die Cutter: Pros and Cons

When it comes to deciding between a CNC machine and a die cutter, there are a few factors to consider. Here are some of the pros and cons of each method:

CNC Machine:

- Pros:

- Versatile – can be programmed to create a wide range of shapes and sizes

- Precise and accurate – can produce consistent results

- Can cut a variety of materials

- Cons:

- Expensive – can cost thousands of dollars

- Requires a computer program to operate

Die Cutter:

- Pros:

- Less expensive than CNC machines

- Doesn’t require electricity or a computer program to operate

- Good for cutting paper, cardboard, and other thin materials

- Cons:

- Not as versatile as CNC machines

- Can’t produce as precise or accurate cuts

- Can only cut pre-made shapes

Which One is Better?

So which method is better – a CNC machine or a die cutter? The answer, as with many things, is that it depends on your needs.

If you need to create a wide range of shapes and sizes, or if you need precise and accurate cuts, a CNC machine is likely the better choice. While they are more expensive, they offer greater versatility and accuracy.

On the other hand, if you primarily work with paper, cardboard, or other thin materials, a die cutter may be a better fit. They are less expensive and don’t require a computer program to operate.

Ultimately, the decision between a CNC machine and a die cutter comes down to your specific needs and budget. By considering the pros and cons of each method, you can make an informed decision that will help you achieve your manufacturing or crafting goals.

Frequently Asked Questions

When it comes to manufacturing, two of the most popular cutting methods are CNC machines and die cutters. Both have their own unique advantages and disadvantages. In this section, we’ll be addressing some common questions about whether a CNC machine is better than a die cutter.

What is a CNC machine?

A CNC (Computer Numerical Control) machine is a manufacturing tool that uses pre-programmed computer software to control and move various cutting tools. These tools can include drills, lathes, and mills. CNC machines are known for their high accuracy, precision, and ability to produce complex shapes and designs.

In terms of cutting, CNC machines use a rotating cutting tool to remove material from a workpiece. The cutting tool is moved along the x, y, and z-axes using a computer-controlled system, which allows for precise and consistent cuts. CNC machines are commonly used in industries such as aerospace, automotive, and medical device manufacturing.

What is a die cutter?

A die cutter is a manufacturing tool that uses a metal die to cut materials such as paper, cardboard, and fabric. The die is a specially-shaped piece of metal that is used to stamp out the desired shape from the material being cut. Die cutters are commonly used in industries such as packaging, printing, and textiles.

Die cutters can produce high volumes of identical shapes quickly and efficiently. However, die cutters are limited in their ability to produce complex shapes and designs. They are also less precise than CNC machines and require more frequent maintenance to keep the cutting edges of the dies sharp.

What are the advantages of using a CNC machine?

CNC machines offer several advantages over die cutters. First and foremost, CNC machines are capable of producing far more complex shapes and designs than a die cutter. CNC machines can also produce parts with higher precision and accuracy, which is important in industries such as aerospace and medical device manufacturing where parts must meet strict quality standards.

CNC machines are also more versatile than die cutters. They can be used to cut a wide variety of materials, including metal, plastic, and wood. Finally, CNC machines offer greater efficiency and productivity than die cutters, as they can operate continuously and require less manual labor.

What are the disadvantages of using a CNC machine?

One of the main disadvantages of using a CNC machine is the cost. CNC machines are significantly more expensive than die cutters, both in terms of initial investment and ongoing maintenance costs. Additionally, CNC machines require specialized software and training to operate, which can add to the overall cost of using the machine.

CNC machines are also slower than die cutters when it comes to producing large quantities of identical parts. This is because each part must be individually programmed and cut, whereas a die cutter can stamp out hundreds or thousands of identical shapes in a short amount of time.

When should I use a CNC machine instead of a die cutter?

If you need to produce complex shapes or designs, require high precision and accuracy, or need to cut a variety of materials, a CNC machine is likely the better choice. CNC machines are also a good option if you need to produce smaller quantities of parts or if you require a high level of customization.

On the other hand, if you need to produce large quantities of simple shapes quickly and efficiently, a die cutter may be the better choice. Die cutters are also a good option if you are on a tight budget or if you need to produce parts that don’t require a high level of precision or accuracy.

In conclusion, the debate between a CNC machine and a die cutter is not a straightforward one. Both have their advantages and disadvantages, and the choice ultimately depends on the specific needs of the user.

However, it’s important to note that CNC machines offer greater precision and versatility, allowing for a wider range of designs to be created with ease. Additionally, they require less manual labor and can be operated with greater efficiency, making them a more cost-effective option in the long run.

On the other hand, die cutters may be a better choice for smaller production runs or simpler designs, as they are generally more affordable and require less setup time. They are also easier to operate and require less technical expertise, making them a good option for beginners.

In the end, the decision between a CNC machine and a die cutter comes down to the individual needs and preferences of the user. It’s important to carefully consider the specific requirements of each project before making a final decision.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com