CNC machining and milling are two terms that are often used interchangeably. However, they are not the same thing. While both processes involve removing material from a workpiece, they differ in several key ways.

CNC machining involves the use of computer-controlled machines to produce complex parts with high precision. Milling, on the other hand, is a specific type of machining process that involves rotating a cutting tool to remove material from a workpiece. Understanding the differences between these two processes is crucial for anyone looking to get into the world of manufacturing or engineering. In this article, we’ll take a closer look at CNC machining and milling, and explore the similarities and differences between the two.

CNC machining and milling are not the same thing, although they are related. CNC machining refers to a process of using computerized controls to manipulate tools to create a desired shape or design. Milling, on the other hand, is a specific type of CNC machining that involves using rotary cutters to remove material from a workpiece. While milling is a type of CNC machining, they are not interchangeable terms.

Is CNC Machining and Milling the Same Thing?

CNC machining and milling are two of the most common manufacturing processes used in modern-day industries. While these two terms are often used interchangeably, they are not exactly the same thing. In this article, we will explore the differences between CNC machining and milling and discuss their benefits and drawbacks.

What is CNC Machining?

CNC machining, or Computer Numerical Control machining, is a manufacturing process that uses computerized controls and machine tools to produce complex parts and components with high precision. CNC machines are programmed using software that controls the movement and operation of the machine, allowing for precise cuts, drilling, and shaping of materials.

CNC machines are used in a variety of industries, including aerospace, automotive, medical, and electronics manufacturing. They are capable of producing parts made from a variety of materials, including metals, plastics, and composites.

Some of the benefits of CNC machining include:

- High precision and accuracy

- Faster production times

- Consistent quality

- Reduced waste and material costs

- Ability to produce complex shapes and designs

However, CNC machines can also be expensive to purchase and maintain, and the programming and setup process can be time-consuming and complex.

What is Milling?

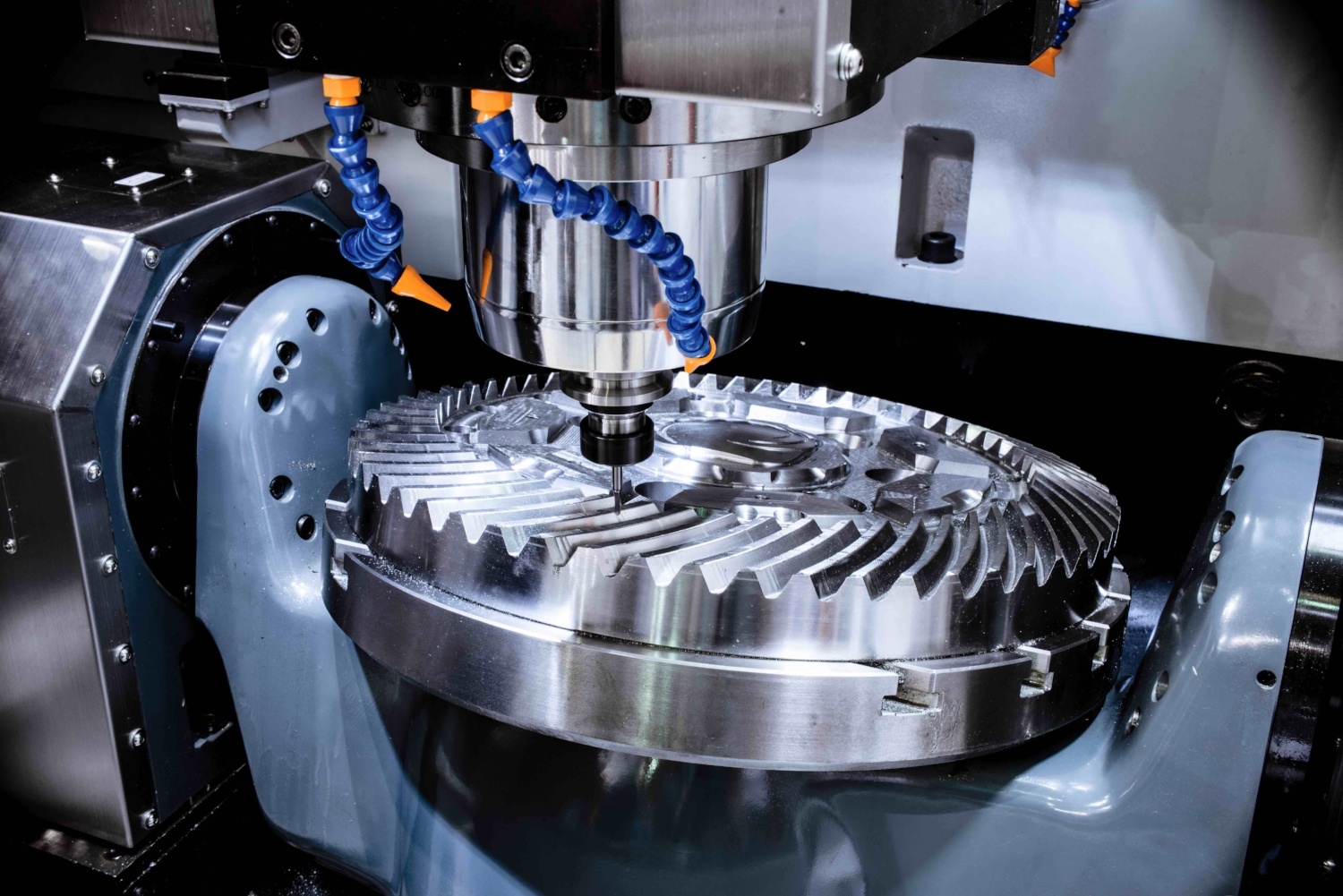

Milling is a machining process that uses a rotating cutter to remove material from a workpiece. The cutter is typically a multi-point tool that moves along multiple axes, allowing for precise cuts and shaping of the material. Milling can be done manually or using a computer-controlled milling machine.

Milling is commonly used in the manufacturing of metal parts, but can also be used for plastics and other materials. It is a versatile process that can produce a wide range of shapes and sizes.

Some of the benefits of milling include:

- Ability to produce complex shapes and designs

- High precision and accuracy

- Faster production times compared to manual machining

- Consistent quality

- Reduced waste and material costs

However, milling can also be a labor-intensive process, and the cost of manual milling can be high due to the skilled labor required. Additionally, manual milling can be less precise than CNC milling and may result in more waste and material costs.

CNC Machining vs. Milling: Which is Better?

Both CNC machining and milling have their advantages and disadvantages, and the choice between the two will depend on the specific needs of the project.

CNC machining is generally faster and more precise than manual milling, making it ideal for large production runs or complex parts with tight tolerances. It also has the benefit of being programmable, which allows for consistent quality and reduced waste.

Milling, on the other hand, is better suited for smaller production runs or one-off parts. It can also be more cost-effective for simpler parts, as the cost of programming and setup for CNC machining can be high.

Conclusion

While CNC machining and milling are not exactly the same thing, they are both important manufacturing processes used in a variety of industries. Whether you choose CNC machining or milling will depend on the specific needs of your project, including the complexity of the part, the required precision, and the production volume.

Frequently Asked Questions

Is CNC Machining and Milling the Same Thing?

CNC machining and milling are not the same thing, but milling is a type of CNC machining. CNC machining refers to any process that uses computer numerical control (CNC) to control the movement of tools and machines. This can include milling, drilling, turning, and other operations. Milling specifically refers to the process of using rotary cutters to remove material from a workpiece.

Milling is a type of CNC machining that is used to create complex shapes and designs. It involves the use of a cutting tool that rotates around an axis, while the workpiece is held in place. The cutting tool removes material from the workpiece, creating the desired shape or design. While milling is just one type of CNC machining, it is often used interchangeably with the term CNC machining.

What is the Difference Between CNC Machining and Traditional Machining?

The main difference between CNC machining and traditional machining is the level of automation and precision. Traditional machining involves manually operating machines using hand tools or other non-automated methods. CNC machining, on the other hand, uses computer programs to control the movement of machines and tools. This allows for extremely precise and accurate cuts, as well as the ability to create complex shapes and designs.

Another difference is the level of skill required. Traditional machining often requires a high level of skill and experience, as the operator must manually control the cutting tool. CNC machining, however, can be operated by someone with less experience, as the computer program controls the movement of the machine.

What is CNC Milling Used For?

CNC milling is used for a variety of applications, including creating complex shapes and designs, producing parts with high precision, and creating prototypes. It is commonly used in industries such as aerospace, automotive, and medical device manufacturing. CNC milling can be used to create parts made from a variety of materials, including metals, plastics, and wood.

Because of its high level of precision, CNC milling is often used for creating parts with tight tolerances. This makes it particularly useful for creating parts that need to fit together precisely, or for creating parts that require a high degree of accuracy, such as those used in medical devices.

What are the Advantages of CNC Milling?

There are several advantages to using CNC milling over traditional machining methods. One advantage is the level of precision that can be achieved. CNC milling allows for extremely precise cuts, which can be difficult to achieve with traditional machining methods.

Another advantage is the ability to create complex shapes and designs. CNC milling machines can be programmed to create almost any shape or design, making it a versatile manufacturing method. Additionally, CNC milling is a more efficient process than traditional machining, as it can be automated and requires less manual labor.

What are the Limitations of CNC Milling?

While CNC milling has many advantages, there are also some limitations to the process. One limitation is the cost of the machinery. CNC milling machines can be expensive to purchase and maintain, which can make it difficult for smaller businesses to invest in this technology.

Another limitation is the size of the workpiece. CNC milling machines are typically limited in the size of the workpiece they can accommodate, which can limit the types of projects that can be produced. Additionally, CNC milling may not be the best option for certain materials, such as those that are brittle or prone to cracking.

In conclusion, while CNC machining and milling are often used interchangeably, they are not the same thing. CNC machining refers to the process of using computer numerical control to automate various manufacturing processes. On the other hand, milling is a specific type of CNC machining that involves removing material from a workpiece using rotary cutters.

It is important to understand the distinction between these two processes as they have different applications and advantages. CNC machining, in general, offers greater precision and consistency, while milling is ideal for creating complex, three-dimensional shapes. Depending on the specific needs of a project, one may be more suitable than the other.

Overall, whether you are a manufacturer, engineer, or hobbyist, understanding the differences between CNC machining and milling can help you make informed decisions about your manufacturing processes. By leveraging the unique benefits of each approach, you can achieve better results and improve the efficiency of your operations.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com