Table of Contents

- Die Casting and Photovoltaic Cells: A Comprehensive Overview

- Frequently Asked Questions

- 1. What is die casting?

- 2. Are photovoltaic cells made using die casting?

- 3. What are the advantages of using die casting in photovoltaic cell production?

- 4. What other manufacturing processes are used in photovoltaic cell production?

- 5. What is the future of die casting in photovoltaic cell production?

Photovoltaic cells, also known as solar cells, are a popular source of renewable energy. They convert sunlight into electricity and are widely used in household appliances, solar panels, and other devices. But have you ever wondered how these cells are made? One of the manufacturing processes used to create photovoltaic cells is die casting.

Die casting is a method of casting metal into specific shapes and sizes using high-pressure injection. It is commonly used in the production of automotive parts, electronic components, and even toys. However, die casting is also used in the creation of some photovoltaic cells. In this article, we will explore the role of die casting in the production of photovoltaic cells and its impact on the solar energy industry.

Die Casting and Photovoltaic Cells: A Comprehensive Overview

What is Die Casting?

Die casting is a manufacturing process that involves injecting molten metal into a mold, which is then cooled and solidified to create a specific shape or design. This process is widely used in various industries, including automotive, aerospace, and electronics, due to its efficiency and accuracy in producing high-quality parts.

Types of Die Casting

There are two main types of die casting: hot chamber and cold chamber. Hot chamber die casting is commonly used for small and lightweight components, such as zinc-based alloys, due to its ability to maintain a consistent temperature. Cold chamber die casting, on the other hand, is used for larger and heavier components, such as aluminum and copper alloys, which require a higher melting point.

Advantages of Die Casting

Die casting offers several advantages over other manufacturing processes, such as:

- High precision and accuracy in producing complex shapes and designs

- Efficient and cost-effective production

- Consistent quality and durability of parts

- Wide range of materials to choose from, including alloys and non-ferrous metals

What are Photovoltaic Cells?

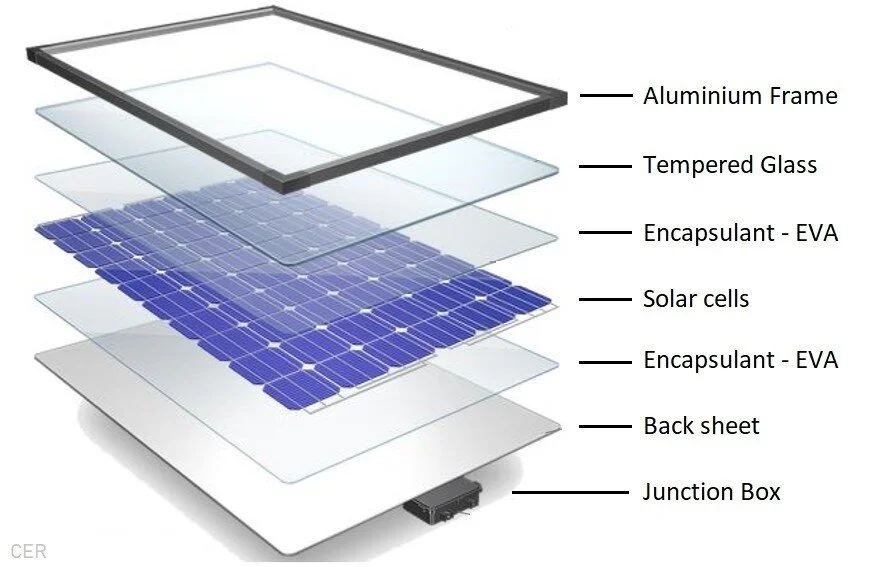

Photovoltaic cells, also known as solar cells, are devices that convert solar energy into electrical energy. These cells are made up of semiconductor materials, such as silicon, that absorb photons from sunlight and release electrons, which are then captured and used to generate electricity.

Types of Photovoltaic Cells

There are three main types of photovoltaic cells: monocrystalline, polycrystalline, and thin-film. Monocrystalline cells are made from a single crystal of silicon and offer the highest efficiency rates, while polycrystalline cells are made from multiple crystals and are more cost-effective. Thin-film cells, on the other hand, are made from layers of semiconductor material and are the most lightweight and flexible option.

Applications of Photovoltaic Cells

Photovoltaic cells are widely used in various applications, such as:

- Solar panels for residential and commercial buildings

- Solar-powered calculators, watches, and other small devices

- Solar-powered streetlights and traffic signals

- Solar-powered satellites and spacecrafts

Can Die Casting be Used in Photovoltaic Cells?

Die casting can be used in the production of photovoltaic cells to create specific components and parts, such as frames, brackets, and connectors. These parts are typically made from aluminum or zinc alloys, which offer high strength and durability while being lightweight and corrosion-resistant.

Benefits of Die Casting in Photovoltaic Cells

Die casting offers several benefits when used in the production of photovoltaic cells, such as:

- Efficient and cost-effective production of high-quality parts

- Accurate and precise shaping of components and parts

- Consistent quality and durability of parts

- Wide range of materials to choose from, including alloys and non-ferrous metals

Die Casting vs Other Manufacturing Processes

Compared to other manufacturing processes, such as stamping and machining, die casting offers several advantages in the production of photovoltaic cells, such as:

| Die Casting | Stamping | Machining |

|---|---|---|

| Accurate and precise shaping of components and parts | Less accurate and precise shaping of components and parts | Less accurate and precise shaping of components and parts |

| Efficient and cost-effective production of high-quality parts | Efficient for high-volume production, but less cost-effective for low-volume production | Less efficient and cost-effective for high-volume production |

| Consistent quality and durability of parts | Inconsistent quality and durability of parts | Varies depending on the material and process used |

| Wide range of materials to choose from, including alloys and non-ferrous metals | Limited to certain materials, such as steel and aluminum | Limited to certain materials, such as steel and aluminum |

Conclusion

Die casting is a versatile and efficient manufacturing process that can be used in the production of photovoltaic cells to create high-quality and durable components and parts. With its ability to shape and mold various materials, die casting offers several advantages over other manufacturing processes and can help to improve the performance and efficiency of photovoltaic cells in various applications.

Frequently Asked Questions

Die casting is a popular manufacturing process used in a variety of industries, but is it also used in the production of photovoltaic cells? Here are some common questions and answers about this topic:

1. What is die casting?

Die casting is a manufacturing process that involves injecting molten metal into a mold, or die, under high pressure. The metal quickly solidifies and takes the shape of the die, creating a part with a precise and uniform shape. This process is often used to create complex parts with fine details.

There are two main types of die casting: hot chamber die casting, which is used for metals with low melting points like zinc, and cold chamber die casting, which is used for metals with high melting points like aluminum and copper.

2. Are photovoltaic cells made using die casting?

While die casting is a popular manufacturing process, it is not commonly used in the production of photovoltaic cells. Photovoltaic cells are made using a variety of processes, including silicon wafering, screen printing, and soldering. These processes involve different manufacturing techniques and equipment than die casting.

However, some companies have experimented with using die casting to produce parts for photovoltaic installations. For example, die casting could be used to create mounting brackets or frames for solar panels. However, the use of die casting in the photovoltaic industry is still relatively uncommon.

3. What are the advantages of using die casting in photovoltaic cell production?

Die casting can offer several advantages for manufacturing parts used in photovoltaic installations. For one, die casting can create parts with a high degree of precision and uniformity, which can be important for ensuring the proper alignment and positioning of solar panels. Additionally, die casting can be a cost-effective way to produce large quantities of parts, which could make it appealing for companies looking to scale up their manufacturing operations.

However, there are also some potential drawbacks to using die casting for photovoltaic cell production, such as the cost of the equipment and the environmental impact of the manufacturing process. As a result, it is not a widely used technique in the industry.

4. What other manufacturing processes are used in photovoltaic cell production?

As mentioned earlier, there are several manufacturing processes used in the production of photovoltaic cells. Some of the most common include silicon wafering, screen printing, and soldering. Silicon wafering involves cutting thin slices of silicon from a larger ingot, which are then processed into solar cells. Screen printing is used to apply conductive paste to the surface of the cells, while soldering is used to connect the cells together to form a solar panel.

Other techniques used in the photovoltaic industry include vacuum deposition, laser processing, and electroplating, among others.

5. What is the future of die casting in photovoltaic cell production?

It is difficult to predict the future of die casting in the photovoltaic industry, as it is not currently a widely used technique. However, as the demand for renewable energy continues to grow, there may be opportunities for die casting to play a larger role in the production of parts for solar installations.

Advances in technology and materials could also make die casting a more attractive option for manufacturing photovoltaic components. For example, the development of new alloys or materials with better thermal properties could make die casting a more effective way to produce parts for solar panels. Ultimately, the future of die casting in the photovoltaic industry will depend on a variety of factors, including cost, efficiency, and environmental impact.

In conclusion, die casting is widely used in the production of photovoltaic cells. This process involves the creation of metal parts with high accuracy and a smooth finish, which is essential for the efficiency of the cells. Die casting also allows for the production of complex shapes and designs, making it a versatile choice for the manufacturing of photovoltaic cells.

Furthermore, die casting is a cost-effective and efficient manufacturing method, allowing for high volume production at a relatively low cost. This makes it an attractive option for the renewable energy industry, where the demand for photovoltaic cells is constantly increasing.

Overall, the use of die casting in photovoltaic cells plays a crucial role in the production of renewable energy. As the world transitions towards sustainable energy sources, die casting will continue to be an important manufacturing process in the development of photovoltaic cells.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com