Table of Contents

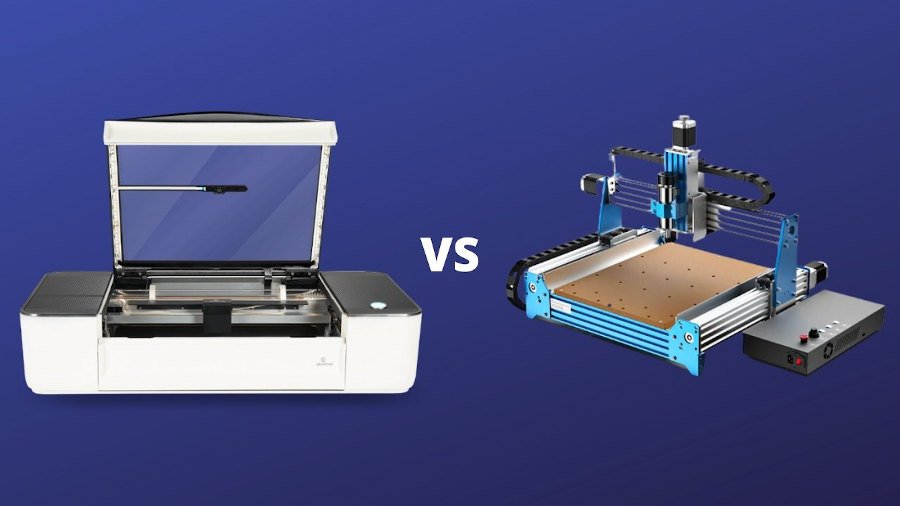

Glowforge is a popular brand that has been making waves in the world of laser engraving and cutting. But the question remains, is Glowforge a CNC machine? CNC (Computer Numerical Control) machines have been around for quite some time, and they are used to produce accurate and precise cuts on a variety of materials. In this article, we will explore the similarities and differences between Glowforge and CNC machines to determine whether or not Glowforge can be considered a CNC machine.

With the rise of technology, various machines have been developed to make our lives easier. One such machine is the CNC machine, which uses computer software to control the cutting process. On the other hand, Glowforge is a laser cutting and engraving machine that uses software to control the laser beam. In this article, we will delve into the inner workings of both machines to provide a comprehensive answer to the question of whether or not Glowforge can be classified as a CNC machine.

Is Glowforge a CNC Machine?

Glowforge has been gaining popularity among hobbyists and professionals in the crafting and manufacturing industries. However, there seems to be some confusion on whether it is a CNC machine or not. In this article, we will dive into the details and answer the question: Is Glowforge a CNC machine?

What is a CNC Machine?

A CNC (Computer Numerical Control) machine is a computer-controlled manufacturing tool that can create precise cuts and shapes on various materials. It works by interpreting a design file and translating it into machine instructions. CNC machines are commonly used in woodworking, metalworking, and 3D printing.

A CNC machine typically has a bed where the material is placed, and a spindle or router that moves along the x, y, and z-axes. The machine cuts and shapes the material according to the design file, producing accurate and repeatable results.

How Does Glowforge Work?

Glowforge is a desktop laser cutter and engraver that uses a CO2 laser to cut and engrave materials such as wood, acrylic, leather, and paper. It has a built-in camera that scans the material before cutting, allowing for precise alignment and placement of designs.

Unlike CNC machines, Glowforge does not have a physical router or cutting bit. Instead, it uses a laser beam to vaporize the material along the path of the design. The laser can also be adjusted to engrave the material to varying depths.

Glowforge Vs CNC Machines

While Glowforge and CNC machines share some similarities, there are also significant differences between the two.

One of the main differences is the type of cutting tool used. CNC machines use a physical router or cutting bit, which can create intricate cuts and shapes on various materials. However, the tool can wear out over time and requires frequent maintenance.

In contrast, Glowforge uses a laser beam that does not wear out and does not require replacement. However, the laser is limited in the types of materials it can cut, and it cannot produce the same level of detail as a CNC machine.

Another difference is the level of precision. CNC machines are known for their accuracy and repeatability, making them ideal for mass production and large-scale projects. Glowforge, on the other hand, is better suited for smaller projects and one-off designs.

Benefits of Glowforge

Despite the differences, Glowforge has several benefits that make it a popular choice for hobbyists and small businesses.

One of the main advantages is its ease of use. Glowforge is designed to be user-friendly and accessible, even for those with no prior experience in laser cutting or design. It has a simple interface and comes with a library of designs that can be customized and edited.

Another benefit is its versatility. Glowforge can cut and engrave a wide range of materials, including wood, acrylic, leather, and paper. It can also engrave on curved surfaces and 3D objects, making it ideal for creating personalized gifts and decorations.

Conclusion

In summary, Glowforge is not a CNC machine in the traditional sense. It uses a laser beam instead of a physical cutting tool and is better suited for smaller projects and one-off designs. However, it has several benefits that make it a popular choice for hobbyists and small businesses, including its ease of use and versatility.

Frequently Asked Questions

Here are some common questions about Glowforge and whether it can be considered a CNC machine:

Is Glowforge a CNC machine?

Yes, Glowforge can be considered a CNC (computer numerical control) machine. It uses a laser to cut and engrave materials such as wood, acrylic, and leather according to a digital design. The laser is controlled by software, allowing for precise and intricate cuts that can be replicated consistently.

However, unlike traditional CNC machines that use drills or routers to cut materials, Glowforge’s laser technology does not produce any chips or dust, making it a cleaner and more user-friendly option. Additionally, Glowforge can also be used for 3D printing and scanning, making it a versatile tool for makers and creators.

What materials can Glowforge cut?

Glowforge can cut a variety of materials including wood, acrylic, leather, paper, fabric, cardboard, and more. The thickness of the material that Glowforge can cut depends on the power of the laser, with the Pro model able to cut through materials up to 1/2 inch thick. However, it is important to note that certain materials such as PVC and polycarbonate can create harmful fumes when cut with a laser and should not be used with Glowforge.

In addition to cutting, Glowforge can also engrave on materials such as glass, metal, and ceramic. The laser can produce intricate designs and even photographs with high resolution and detail.

What software does Glowforge use?

Glowforge uses its own cloud-based software called the Glowforge App. This software allows users to easily upload their designs, set the parameters for the laser, and monitor the progress of the cut or engrave. The Glowforge App also includes a library of pre-made designs and projects, as well as the ability to create designs using vector-based software such as Adobe Illustrator or Inkscape.

Additionally, Glowforge is compatible with third-party software such as LightBurn and K40 Whisperer for more advanced users who want more control over the laser’s settings.

Is Glowforge easy to use?

Yes, Glowforge is designed to be user-friendly and accessible for both beginners and experienced makers. The Glowforge App guides users through the process of setting up the machine, uploading designs, and choosing the correct settings for the material being used. The laser is also enclosed in a safety shield, making it safe to use in homes or small workshops.

However, it is important to follow safety precautions when using any laser cutter, including wearing protective eyewear and ensuring proper ventilation in the workspace.

What is the cost of a Glowforge machine?

Glowforge offers three different models: Basic, Plus, and Pro. The Basic model is priced at $2,495, the Plus model is priced at $3,995, and the Pro model is priced at $5,995. The price difference between the models reflects the power of the laser and the size of the cutting bed, with the Pro model being the most powerful and versatile option. Glowforge also offers financing options for those who want to spread out the cost over time.

In addition to the cost of the machine, users will also need to purchase materials to cut and engrave, such as wood or acrylic sheets. However, Glowforge’s compatibility with a variety of materials means that users can choose from a wide range of affordable options.

In conclusion, after thoroughly researching and analyzing the features and capabilities of the Glowforge, it can be concluded that it is indeed a CNC machine. With its precise laser cutting and engraving abilities, it is able to carve out intricate designs with ease.

Furthermore, the Glowforge’s user-friendly interface and software make it accessible to both beginners and experienced users, allowing for endless creative possibilities. Its compact size and sleek design also make it a convenient addition to any workspace.

Overall, the Glowforge offers a unique combination of CNC technology and user-friendly design, making it a valuable tool for any creative or manufacturing project. So if you’re looking for a versatile and reliable CNC machine, the Glowforge is definitely worth considering.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com