Table of Contents

As technology continues to advance, manufacturers are constantly looking for cost-efficient ways to produce their products. Injection molding is a popular manufacturing process that has been used for decades, but the question remains: is injection molding cost efficient?

Injection molding involves melting plastic pellets and injecting the melted material into a mold to create a specific shape. It is a highly precise process that can produce complex shapes with consistent quality. However, the cost of injection molding depends on various factors, such as the size and complexity of the mold, the material used, and the quantity of parts produced. Let’s explore the cost-effectiveness of injection molding further.

Yes, injection molding is a cost-efficient manufacturing process that can produce high volumes of identical plastic parts. The initial tooling and equipment costs may be high, but the per-unit cost decreases as the production volume increases. Additionally, injection molding allows for precise and complex part designs, reducing the need for post-production assembly. Overall, injection molding is a popular choice for cost-effective plastic part production.

Is Injection Molding Cost Efficient?

Injection molding is a popular manufacturing process used to create a variety of products. From automotive parts to household items, injection molding has revolutionized the way companies produce their products. But is it cost-efficient? In this article, we will explore the cost-effectiveness of injection molding and the benefits it provides.

Lower Cost per Unit

Injection molding is known for its ability to produce large quantities of parts quickly and efficiently. This means that the cost per unit is significantly lower than other manufacturing methods, such as machining or 3D printing. Since injection molding is an automated process, it requires minimal labor, which results in lower labor costs. Additionally, the cost of the raw materials used in injection molding is relatively low, further contributing to the overall cost-effectiveness of the process.

When it comes to producing large quantities of parts, injection molding is the way to go. The process is fast, efficient, and reliable, resulting in a lower cost per unit. This is why injection molding is the preferred method for producing products in industries such as automotive, medical, and consumer goods.

Initial Tooling Costs

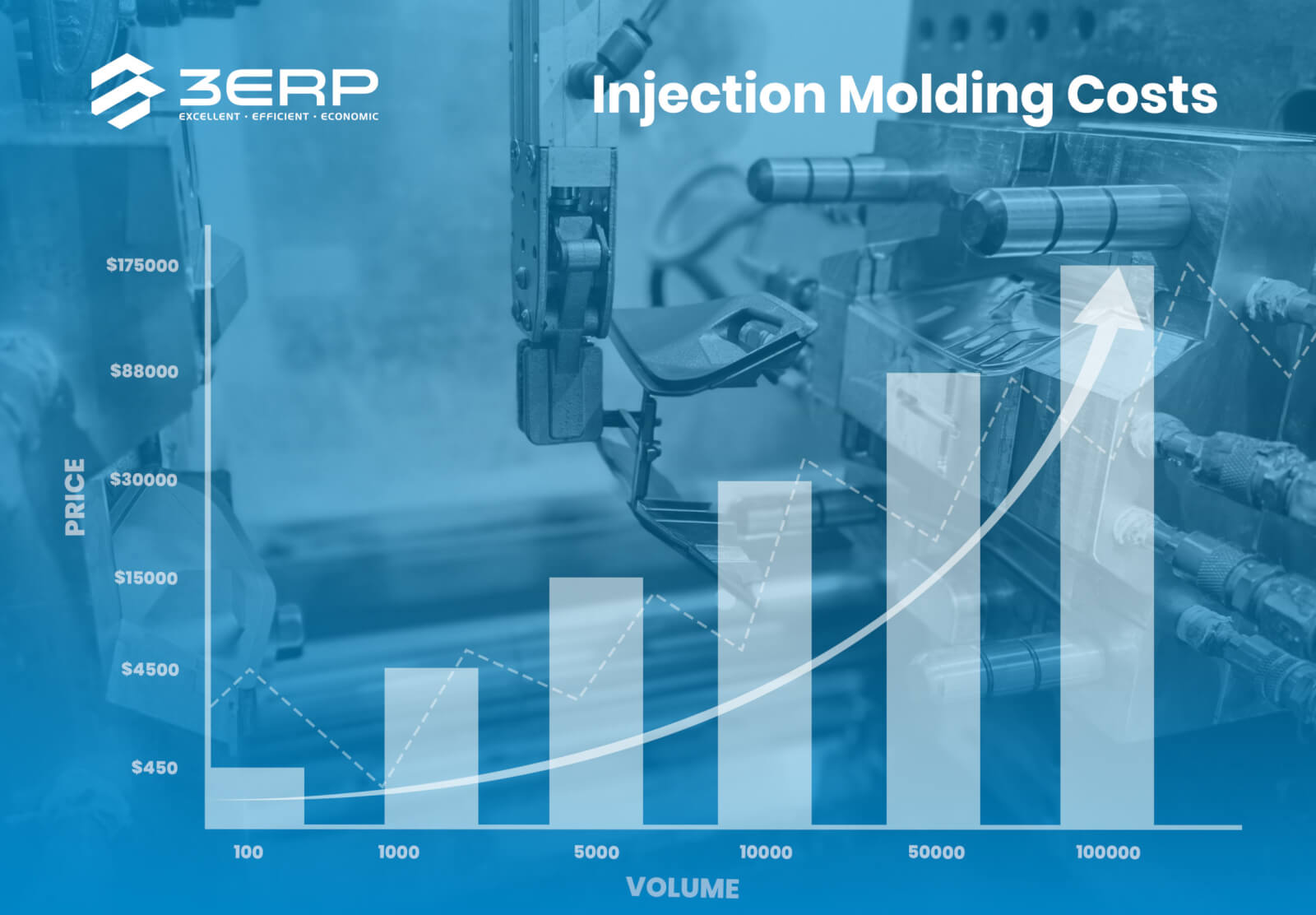

While injection molding may be cost-efficient in the long run, the initial tooling costs can be quite high. The tooling costs include the design and creation of the mold, which can be a significant investment. The cost of the mold will vary depending on the complexity of the part and the material used. However, once the mold is created, it can be used repeatedly, making the cost per unit significantly lower.

It’s important to note that the initial tooling costs can make injection molding less cost-efficient for companies looking to produce small quantities of parts. In this case, other manufacturing methods may be more suitable, as they require lower initial investment costs.

Benefits of Injection Molding

Despite the initial tooling costs, injection molding provides numerous benefits that make it a cost-efficient manufacturing process. Some of these benefits include:

- High production output

- Consistent part quality

- Ability to produce complex parts

- Low labor costs

- Minimal waste

These benefits result in a faster time-to-market, improved product quality, and reduced overall costs. Injection molding is also a highly scalable process, meaning that companies can easily increase or decrease production output as needed.

Injection Molding vs. Other Manufacturing Methods

When comparing injection molding to other manufacturing methods, such as machining or 3D printing, injection molding is typically the more cost-efficient option. Machining requires a significant amount of labor, which results in higher labor costs. Additionally, the cost of the raw materials used in machining can be higher than those used in injection molding.

3D printing, on the other hand, is a slower process that is typically used for producing small quantities of parts. While the initial investment costs for 3D printing are lower, the cost per unit is typically higher than injection molding.

Overall, injection molding provides a cost-efficient manufacturing solution for companies looking to produce large quantities of parts quickly and efficiently. While the initial tooling costs may be high, the benefits of injection molding far outweigh the costs in the long run.

Frequently Asked Questions

Injection molding is a manufacturing process used to produce a large volume of identical parts. It involves the use of a mold, molten plastic, and an injection molding machine. However, many people wonder if injection molding is cost-efficient. Here are some frequently asked questions and their answers.

1. How does injection molding work?

Injection molding works by injecting molten plastic material into a mold cavity. The plastic material is fed into the injection molding machine and melted by heat and pressure. Once the plastic has melted, it is injected into the mold cavity, where it cools and solidifies into the desired shape. The mold is then opened, and the finished part is ejected.

Injection molding is a highly precise process that can produce complex parts with very tight tolerances. It is also a very efficient process, as it can produce a large volume of parts quickly and with little waste.

2. What are the advantages of injection molding?

There are several advantages of injection molding, including:

- High production rates

- Consistent quality

- Ability to use a wide range of materials

- Low labor costs

Injection molding is also very versatile and can be used to produce parts with a wide range of shapes and sizes. It is a cost-effective method for producing large volumes of identical parts.

3. Is injection molding cost-efficient?

Injection molding can be cost-efficient, depending on the volume of parts being produced. The initial tooling costs can be high, but the cost per part decreases as the volume of parts increases. Injection molding is often used to produce high-volume parts, such as automotive components and consumer electronic parts.

Injection molding can also be cost-efficient when compared to other manufacturing processes, such as machining or casting. Injection molding requires less labor and can produce parts with more complex shapes and tighter tolerances than other processes.

4. What factors affect the cost of injection molding?

Several factors can affect the cost of injection molding, including:

- Tooling costs

- Material costs

- Machine costs

- Labor costs

- Part complexity

The cost of injection molding can vary depending on the size and complexity of the part being produced. However, injection molding is often a cost-effective method for producing high-volume parts.

5. How can I reduce the cost of injection molding?

There are several ways to reduce the cost of injection molding, including:

- Optimizing the design of the part to minimize material usage

- Using a lower-cost material

- Increasing the volume of parts being produced

- Reducing the complexity of the part

Working with an experienced injection molding company can also help reduce costs by optimizing the manufacturing process and minimizing waste.

In conclusion, injection molding can be a cost-efficient production process when implemented correctly. The upfront costs associated with designing and creating molds can seem daunting, but the long-term benefits outweigh the initial investment. Once the molds are created, the production process can be streamlined, reducing labor costs and increasing efficiency.

Additionally, injection molding allows for the production of high-quality, precise parts at a rapid rate. This means that larger quantities of parts can be produced in a shorter amount of time, reducing costs even further. The ability to produce parts with consistent quality also reduces the need for rework or repairs, saving time and money.

Overall, while injection molding may not be the most cost-efficient option for every production need, it is a viable and often preferred option for many industries. By considering the benefits and costs associated with injection molding, companies can make informed decisions about their production process and ultimately increase their bottom line.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com