Steel is a versatile material that has been used in various industries for its strength and durability. Die casting, on the other hand, is a manufacturing process that involves injecting molten metal into a mold to create complex shapes with high precision. But can steel be considered a material for die casting?

Many people wonder if steel is a suitable material for die casting, given its hardness and high melting point. In this article, we will explore the characteristics of steel and how they relate to the die casting process, as well as the advantages and disadvantages of using steel in die casting applications.

Yes, steel can be considered a material that can be used for die casting.

Die casting is a manufacturing process in which molten metal is forced into a mold cavity under high pressure. Steel is a commonly used material for die casting, as it is strong, durable and can withstand high temperatures. Steel also has excellent machining properties, making it easy to create complex shapes and designs. Overall, steel is a versatile material that is well-suited for die casting in a variety of applications.

Is Steel a Material That Can Be Considered Die Casting?

When it comes to die casting, the type of metal used is crucial for the success of the process. While aluminum and zinc are the most commonly used materials in die casting, steel is also an option that can be considered. In this article, we will explore whether steel can be considered a material for die casting and its benefits compared to other materials.

What is Steel Die Casting?

Steel die casting is a manufacturing process that involves injecting molten steel into a mold under high pressure. The mold is typically made of two parts, the cavity and the ejector, and the molten steel is injected through a sprue. Once the steel has solidified, the mold is opened, and the finished part is ejected.

Steel die casting is commonly used in the automotive and aerospace industries for parts that require high strength and durability. Some examples include engine blocks, transmission cases, and brake components.

Benefits of Steel Die Casting

There are several benefits to using steel in die casting. One of the main advantages is its strength and durability. Steel is a strong and robust material that can withstand high stress and pressure, making it an ideal choice for parts that require high strength.

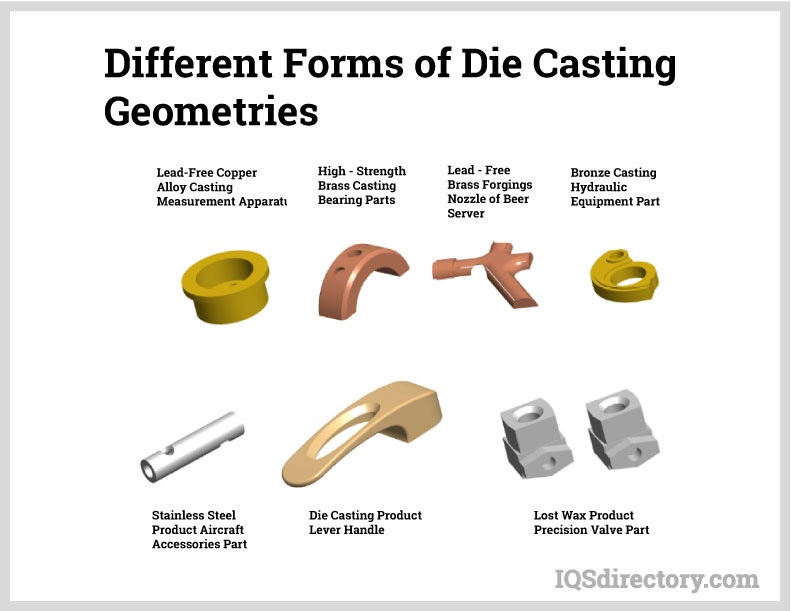

Another benefit of steel die casting is its ability to produce complex shapes and designs. The high pressure used in the process allows for intricate details and fine tolerances, making it possible to create parts with complex geometries and intricate patterns.

Steel vs. Aluminum Die Casting

While steel die casting has its advantages, it also has some disadvantages compared to other materials such as aluminum. One of the main drawbacks of steel is its weight. Steel is a denser material than aluminum, which makes it heavier and more challenging to handle.

Another disadvantage of steel die casting is its cost. Steel is more expensive than aluminum, which can make it less economical for some applications.

Benefits of Aluminum Die Casting

Aluminum die casting is a popular choice for many applications due to its lightweight and cost-effective nature. Aluminum is also an excellent conductor of heat and electricity, making it ideal for parts that require efficient heat dissipation.

Another benefit of aluminum die casting is its versatility. Aluminum can be easily machined, welded, and plated, making it a versatile material that can be used in a wide range of applications.

Steel vs. Zinc Die Casting

Zinc is another common material used in die casting, particularly for smaller parts. Zinc die casting is known for its excellent dimensional stability and high precision, making it suitable for parts that require tight tolerances.

Compared to steel, zinc is a lighter material that is easier to handle and process. Zinc is also more cost-effective than steel, making it a popular choice for high-volume production runs.

Benefits of Zinc Die Casting

Some of the main benefits of zinc die casting include its excellent corrosion resistance, its ability to produce complex shapes, and its low melting point. Zinc also has excellent mechanical properties, such as high strength and hardness, making it an ideal choice for parts that require high durability.

Conclusion

In conclusion, steel can be considered a material for die casting, particularly for parts that require high strength and durability. However, it also has some drawbacks compared to other materials such as aluminum and zinc, including its weight and cost. When choosing a material for die casting, it is essential to consider the specific requirements of the part and the application to determine the best material for the job.

Freequently Asked Questions

Here are some frequently asked questions about whether steel is a material that can be considered die casting:

1. Can steel be used in die casting?

Yes, steel is a material that can be used in die casting. The process of die casting involves melting metal and injecting it into a steel mold under high pressure. Steel molds are typically used for high-volume production runs because they are durable and can withstand the high temperatures and pressures involved in the process.

Steel is a popular choice for die casting because it offers good mechanical properties, such as strength, toughness, and wear resistance. It also has good thermal conductivity, which allows for faster cooling times and better dimensional accuracy of the final product.

2. What are the advantages of using steel in die casting?

There are several advantages to using steel in die casting. First, steel molds are durable and can withstand high temperatures and pressures, making them ideal for high-volume production runs. Second, steel offers good mechanical properties, such as strength, toughness, and wear resistance, which are important for producing high-quality parts.

Finally, steel has good thermal conductivity, which allows for faster cooling times and better dimensional accuracy of the final product. This means that parts made from steel can be produced more quickly and with greater precision than those made from other materials.

3. Are there any disadvantages to using steel in die casting?

While there are many advantages to using steel in die casting, there are also some disadvantages. First, steel molds are expensive to produce and require a significant investment up front. Second, steel is a heavy material, which can make it difficult to handle and transport.

Finally, steel has a high melting point, which means it requires a lot of energy to melt and can take longer to cool than other materials. This can result in longer cycle times and higher production costs.

4. What types of steel are commonly used in die casting?

There are several types of steel that are commonly used in die casting. These include tool steel, which is a high-strength alloy steel that is used for making molds and dies, and stainless steel, which is a corrosion-resistant steel that is often used for producing parts that will be exposed to harsh environments.

Other types of steel that are used in die casting include carbon steel, which is a strong and durable steel that is often used for producing automotive parts, and low alloy steel, which is a type of steel that contains small amounts of other metals to improve its properties.

5. What factors should be considered when choosing steel for die casting?

When choosing steel for die casting, several factors should be considered. First, the properties of the steel, such as its strength, toughness, and wear resistance, should be evaluated to ensure it is suitable for the intended application.

Second, the cost of the steel and the production process should be considered, as this can have a significant impact on the overall cost of the project. Finally, the experience and expertise of the die casting manufacturer should be taken into account, as this can affect the quality and consistency of the final product.

In conclusion, steel is a material that can be considered for die casting. Its properties make it an ideal choice for producing complex shapes and designs with precision and accuracy. With its high strength and durability, steel can withstand extreme temperatures and pressure, making it suitable for a variety of industrial applications.

Furthermore, steel’s versatility and adaptability make it a popular choice for die casting manufacturers worldwide. With its ability to be easily machined and formed into different shapes, steel can be used to create intricate parts and components for a wide range of industries, including aerospace, automotive, and electronics.

Overall, whether you are looking for strength, durability, or precision, steel is a material that can be relied upon for die casting. Its unique properties and characteristics make it a valuable asset in the manufacturing industry, and its versatility ensures that it will remain a popular choice for years to come.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com