Table of Contents

When it comes to purchasing a CNC machine, one of the most common questions people ask is whether they should buy a 2D or 3D machine. The answer to this question depends on a variety of factors, including the type of work you plan to do, your budget, and your level of expertise. In this article, we’ll explore the differences between 2D and 3D CNC machines and help you determine which one is right for your needs. So, if you’re considering purchasing a CNC machine, read on to learn more!

Should I Buy a 2D or 3D CNC Machine?

Understanding the Differences Between 2D and 3D CNC Machines

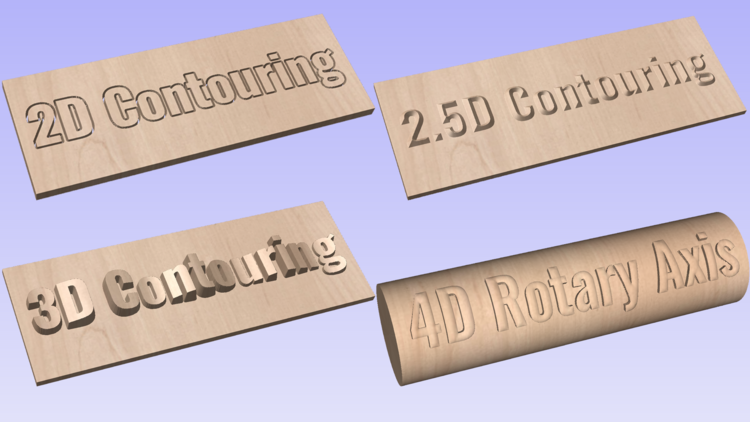

When it comes to CNC machines, there are two main types to choose from: 2D and 3D. A 2D CNC machine is best suited for cutting flat materials, while a 3D CNC machine can create more intricate designs and shapes.

2D CNC machines are typically less expensive and easier to operate than 3D CNC machines. They are ideal for cutting simple shapes and designs, such as signs or furniture parts. A 2D CNC machine uses a router to cut through materials like wood, plastic, or metal. The router moves along two axes, the X and Y, and the cutting depth is controlled by the Z-axis.

On the other hand, 3D CNC machines are more complex and expensive than their 2D counterparts. They use advanced software to create intricate designs and shapes. 3D CNC machines can be used to create anything from sculptures to automotive parts. They use a variety of tools, including a spindle, laser, or plasma cutter, to cut through materials. 3D CNC machines move along three axes, X, Y, and Z, and can rotate the material being cut to create complex shapes.

The Benefits of a 2D CNC Machine

If you are considering purchasing a CNC machine, a 2D machine may be the best option for you. Here are a few benefits of a 2D CNC machine:

1. Affordability: 2D CNC machines are less expensive than 3D machines, making them a more budget-friendly option.

2. Ease of Use: Because 2D CNC machines are simpler in design, they are easier to operate and require less training.

3. Versatility: While 2D CNC machines are best suited for cutting flat materials, they can be used for a variety of applications, including signage, furniture, and cabinetry.

The Benefits of a 3D CNC Machine

While 2D CNC machines have their benefits, a 3D CNC machine can provide even more capabilities. Here are a few benefits of a 3D CNC machine:

1. Advanced Design Capabilities: 3D CNC machines use advanced software to create intricate designs and shapes, allowing for more complex projects.

2. Precision: 3D CNC machines can cut with greater precision than 2D machines, making them ideal for creating intricate parts.

3. Speed: Because 3D CNC machines use multiple tools, they can complete a project more quickly than a 2D machine.

2D CNC Machine Vs 3D CNC Machine

While both 2D and 3D CNC machines have their benefits, there are a few key differences to consider. Here are a few points to compare:

1. Cost: 2D CNC machines are less expensive than 3D machines.

2. Complexity: 3D CNC machines are more complex and require more training to operate.

3. Design Capabilities: 3D CNC machines offer more advanced design capabilities than 2D machines.

4. Precision: 3D CNC machines can cut with greater precision than 2D machines.

5. Speed: 3D CNC machines can complete projects more quickly than 2D machines.

Conclusion

In the end, the decision to buy a 2D or 3D CNC machine depends on your specific needs and budget. If you are looking for a machine that can handle simple projects at an affordable price point, a 2D CNC machine may be the best option for you. However, if you need a machine that can create complex designs with precision and speed, a 3D CNC machine may be worth the investment.

Frequently Asked Questions

When it comes to purchasing a CNC machine, one of the biggest decisions you will need to make is whether to buy a 2D or 3D machine. Here are some common questions and answers to help you make an informed decision:

What is the difference between a 2D and 3D CNC machine?

A 2D CNC machine is designed to cut flat materials, such as sheet metal or wood, with two axes of motion (X and Y). Meanwhile, a 3D CNC machine is capable of cutting materials in three dimensions, with an additional axis of motion (Z) allowing for more complex designs and shapes.

While a 2D machine is great for simple designs and projects, a 3D machine is necessary for more complex and intricate designs, especially those that require curved or rounded edges.

Is a 3D CNC machine more expensive than a 2D machine?

Generally speaking, yes, a 3D CNC machine is more expensive than a 2D machine. This is because it requires more advanced technology and components, such as an additional axis of motion, to create more complex designs. However, it is important to consider your needs and the types of projects you will be working on before making a decision solely based on cost.

If you plan on working on primarily flat materials and simple designs, a 2D machine may be the more cost-effective option. However, if you need to create more complex and intricate designs, a 3D machine may be worth the investment in the long run.

Can a 2D CNC machine be upgraded to a 3D machine?

While some 2D machines may have the option to add a third axis of motion, it is not as simple as just adding a new component. Upgrading a 2D machine to a 3D machine requires significant modifications and upgrades, and may not be cost-effective compared to simply purchasing a new 3D machine.

If you anticipate needing a 3D machine in the future, it is best to purchase the appropriate machine from the beginning to avoid additional costs and modifications down the line.

What are the benefits of a 3D CNC machine?

One of the biggest benefits of a 3D CNC machine is the ability to create more complex and intricate designs, thanks to the additional axis of motion. This allows for more creative freedom and the ability to create unique shapes and designs that may not be possible with a 2D machine.

In addition, a 3D machine can increase efficiency and productivity by reducing the need for manual labor and reducing the risk of errors and mistakes. This can ultimately save time and money in the long run.

What factors should I consider when deciding between a 2D and 3D CNC machine?

When deciding between a 2D and 3D CNC machine, it is important to consider your specific needs and the types of projects you will be working on. If you primarily work with flat materials and simple designs, a 2D machine may be the more cost-effective option.

However, if you need to create more complex and intricate designs, a 3D machine may be necessary. It is also important to consider your budget and the long-term costs and benefits of each option before making a decision.

In conclusion, the decision to buy a 2D or 3D CNC machine ultimately depends on your specific needs and budget. If you are looking for a machine that can produce intricate designs and complex shapes, a 3D CNC machine is the way to go. However, if your projects only require simple cuts and engraving, a 2D CNC machine is more cost-effective and efficient.

Another factor to consider is the learning curve. 3D CNC machines require more knowledge and experience to operate effectively, while 2D CNC machines are relatively easy to learn and use.

Ultimately, it’s essential to weigh the pros and cons of each machine and consider your unique situation before making a final decision. Whether you opt for a 2D or 3D CNC machine, both will undoubtedly bring your projects to life and take your craftsmanship to the next level.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com