Table of Contents

- Frequently Asked Questions

- What Are Standard Commercial Tolerances for Aluminum Extrusions?

- How Are Standard Commercial Tolerances Determined?

- What Is the Importance of Standard Commercial Tolerances for Aluminum Extrusions?

- How Are Commercial Tolerances Verified or Inspected?

- Can Custom Tolerances Be Established for Aluminum Extrusions?

As the demand for aluminum extrusions continues to grow, it is important to understand the concept of standard commercial tolerances. These tolerances are critical in ensuring the quality and consistency of aluminum extrusions in various industries such as construction, automotive, aerospace, and more.

In this article, we will explore the definition of standard commercial tolerances, their importance in the extrusion process, and how they affect the final product. Whether you are a manufacturer, designer, or consumer of aluminum extrusions, understanding these tolerances is crucial for achieving optimal results in your projects. So, let’s dive in and learn more about standard commercial tolerances for aluminum extrusions.

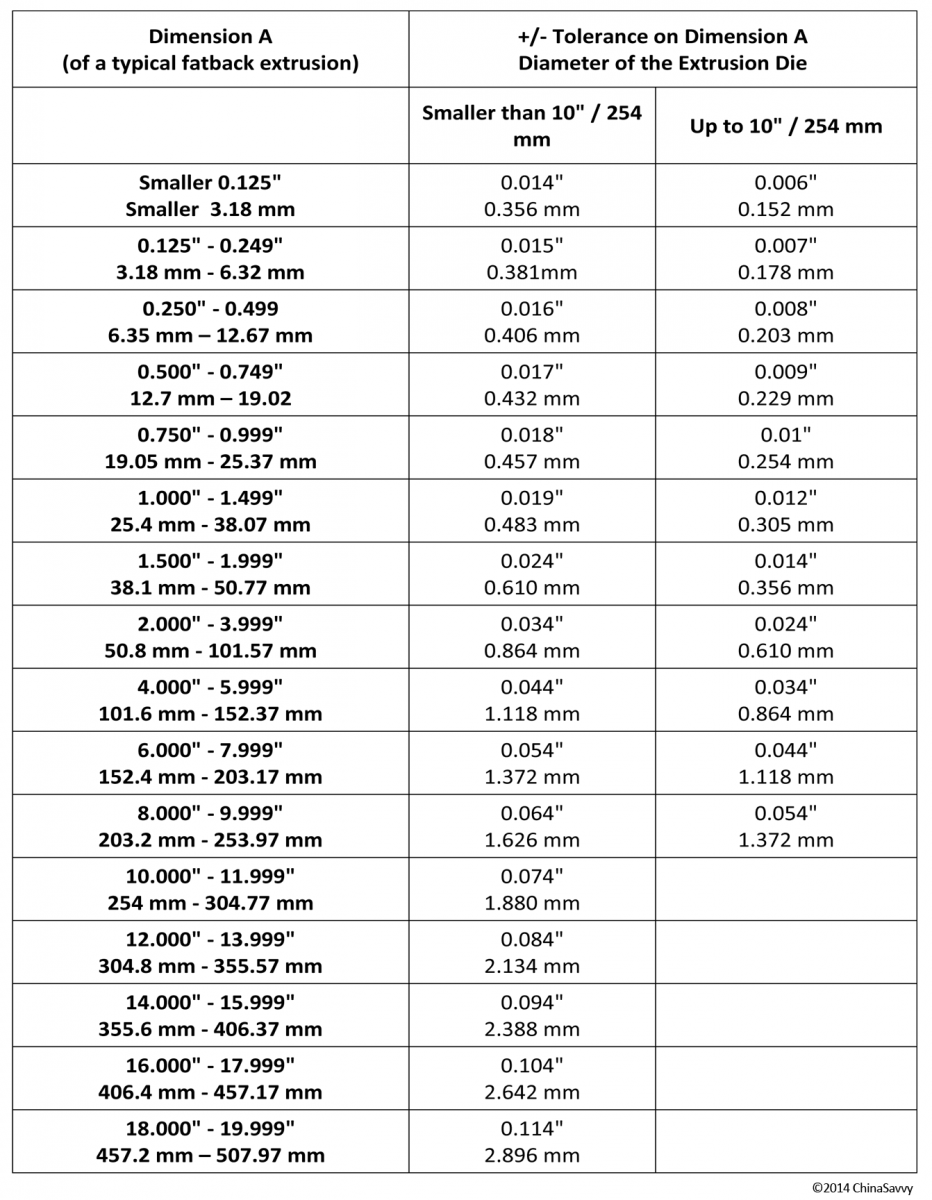

What Are Standard Commercial Tolerances for Aluminum Extrusions? Standard commercial tolerances for aluminum extrusions refer to the acceptable deviation in dimensions and properties during the manufacturing process. The level of tolerance may vary depending on the complexity of the design and the manufacturing method used. However, the industry standard tolerance for aluminum extrusions is typically +/- 0.005 inches for dimensions and +/- 5% for physical properties such as strength and hardness.

Understanding Standard Commercial Tolerances for Aluminum Extrusions

When it comes to manufacturing aluminum extrusions, tolerances play a critical role in ensuring the final product meets the desired specifications. Tolerances refer to the allowable deviation from the exact dimensions or specifications of a product. Understanding the standard commercial tolerances for aluminum extrusions is essential in ensuring quality and precision in the production process.

What are Tolerances for Aluminum Extrusions?

Tolerances in aluminum extrusions refer to the allowable variation in dimensions or other physical attributes of a product. The tolerances are determined by the manufacturing process, the tools used, and the specifications set by the customer.

The standard commercial tolerances for aluminum extrusions are defined by the Aluminum Association and are based on the type of product being manufactured, the alloy used, and the size of the extrusion. These tolerances are categorized into two groups: general tolerances and dimensional tolerances.

General tolerances refer to the allowable variation in the overall shape and appearance of the extrusion. This includes surface finish, straightness, twist, and bow. Dimensional tolerances, on the other hand, refer to the allowable variation in specific dimensions such as width, height, and thickness.

To ensure that the final product meets the desired specifications, it is essential to understand the standard commercial tolerances for aluminum extrusions and work with a reputable manufacturer who adheres to these guidelines.

Benefits of Understanding Tolerances for Aluminum Extrusions

Understanding the standard commercial tolerances for aluminum extrusions offers several benefits, including:

- Ensuring the final product meets the desired specifications

- Reducing the risk of product failure or performance issues

- Improving the overall quality and precision of the product

- Minimizing production costs and waste by avoiding unnecessary rework or scrap

By working with a manufacturer who understands and adheres to these tolerances, you can be confident that your product will meet the required specifications and perform as intended.

Standard Commercial Tolerances Vs. Tighter Tolerances

While the standard commercial tolerances for aluminum extrusions are ideal for most applications, some projects may require tighter tolerances. Tighter tolerances refer to smaller allowable variations in dimensions and physical attributes.

The downside of tighter tolerances is that they can increase production costs and lead times. They may also require specialized equipment and processes, which can further increase costs. However, tighter tolerances may be necessary for certain applications where precision is critical.

When deciding on the tolerances for your aluminum extrusion project, it is essential to consider the intended application, budget, and production timeline. Working with an experienced manufacturer can help you determine the appropriate tolerances for your project.

Conclusion

Understanding the standard commercial tolerances for aluminum extrusions is essential in achieving quality and precision in the manufacturing process. By working with a reputable manufacturer who adheres to these guidelines, you can be confident that your final product will meet the required specifications and perform as intended. Consider the intended application, budget, and production timeline when deciding on tolerances for your project, and work with an experienced manufacturer to ensure success.

Frequently Asked Questions

Aluminum extrusions are widely used in various industries, and it is important to understand the standard commercial tolerances that are applicable to them. Here are some frequently asked questions about standard commercial tolerances for aluminum extrusions:

What Are Standard Commercial Tolerances for Aluminum Extrusions?

Standard commercial tolerances for aluminum extrusions refer to the acceptable degree of variation or deviation in dimensions, surface finish, and other physical properties of the extruded profiles. These tolerances are established by industry standards such as the American National Standards Institute (ANSI) or the Aluminum Association, and they may vary depending on the specific application and the extrusion method used.

For example, the standard tolerance for the thickness of an extruded profile may be +/- 0.005 inches, while the tolerance for the straightness of a 10-foot length may be +/- 0.030 inches. In addition, commercial tolerances may also specify the acceptable range of variation in mechanical properties such as tensile strength or elongation.

How Are Standard Commercial Tolerances Determined?

The determination of standard commercial tolerances for aluminum extrusions involves a combination of factors such as the extrusion process, the material properties, and the intended application. Manufacturers must consider the limitations of their equipment, the variability of raw materials, and the demands of their customers when establishing tolerances.

In general, tolerances are established based on statistical analysis of the production process and the desired level of precision. Manufacturers may also use computer-aided design (CAD) and other software tools to simulate the extrusion process and optimize tolerances for specific geometries and dimensions.

What Is the Importance of Standard Commercial Tolerances for Aluminum Extrusions?

Standard commercial tolerances for aluminum extrusions are important for ensuring the quality and consistency of the finished products. By establishing clear tolerances, manufacturers can minimize the risk of defects, failures, or performance issues that can result from excessive variation or deviation in critical dimensions or properties.

In addition, standard tolerances also help to facilitate communication and collaboration between manufacturers, designers, and customers. By providing clear guidance on what is acceptable and what is not, standard tolerances can help to avoid misunderstandings, disputes, or delays in the production process.

How Are Commercial Tolerances Verified or Inspected?

Commercial tolerances for aluminum extrusions are typically verified or inspected using a variety of tools and techniques. These may include visual inspection, dimensional measurement with calibrated equipment, non-destructive testing methods such as ultrasonic or X-ray inspection, or mechanical testing to verify properties such as strength or hardness.

The specific method of verification or inspection will depend on the type of tolerance being evaluated and the resources available. Manufacturers may also establish their own internal inspection procedures or rely on third-party certification or testing services to ensure compliance with industry standards.

Can Custom Tolerances Be Established for Aluminum Extrusions?

Yes, custom tolerances can be established for aluminum extrusions based on specific customer requirements or applications. Custom tolerances may be tighter or looser than standard commercial tolerances, depending on the desired level of precision or functionality.

However, establishing custom tolerances may require additional time, effort, and cost, as manufacturers must adjust their production processes and equipment to meet the specific requirements. Customers should also be aware of the potential trade-offs between tighter tolerances and higher costs or longer lead times.

In conclusion, understanding the standard commercial tolerances for aluminum extrusions is essential for manufacturers, designers, and architects who work with this versatile material. By knowing the tolerances, they can ensure that their projects meet the required specifications and function optimally.

Furthermore, it is important to note that tolerances may vary depending on the extrusion process, product shape, and size. Therefore, it is crucial to consult with experienced professionals who have the expertise and knowledge to guide you on the best practices for your project.

In conclusion, while standard commercial tolerances for aluminum extrusions may seem complex and technical, they are critical to the success of any project. By working with experts and understanding the tolerances, you can achieve high-quality results that meet your needs and exceed your expectations.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com