Table of Contents

- What Are the 3 Most Important Pvs in CNC Machining?

- Frequently Asked Questions

- What are the 3 most important Pvs in CNC machining?

- Why are Position, Velocity, and Acceleration important in CNC machining?

- How do you optimize Position, Velocity, and Acceleration in CNC machining?

- What are the benefits of optimizing Position, Velocity, and Acceleration in CNC machining?

- What are some common challenges in optimizing Position, Velocity, and Acceleration in CNC machining?

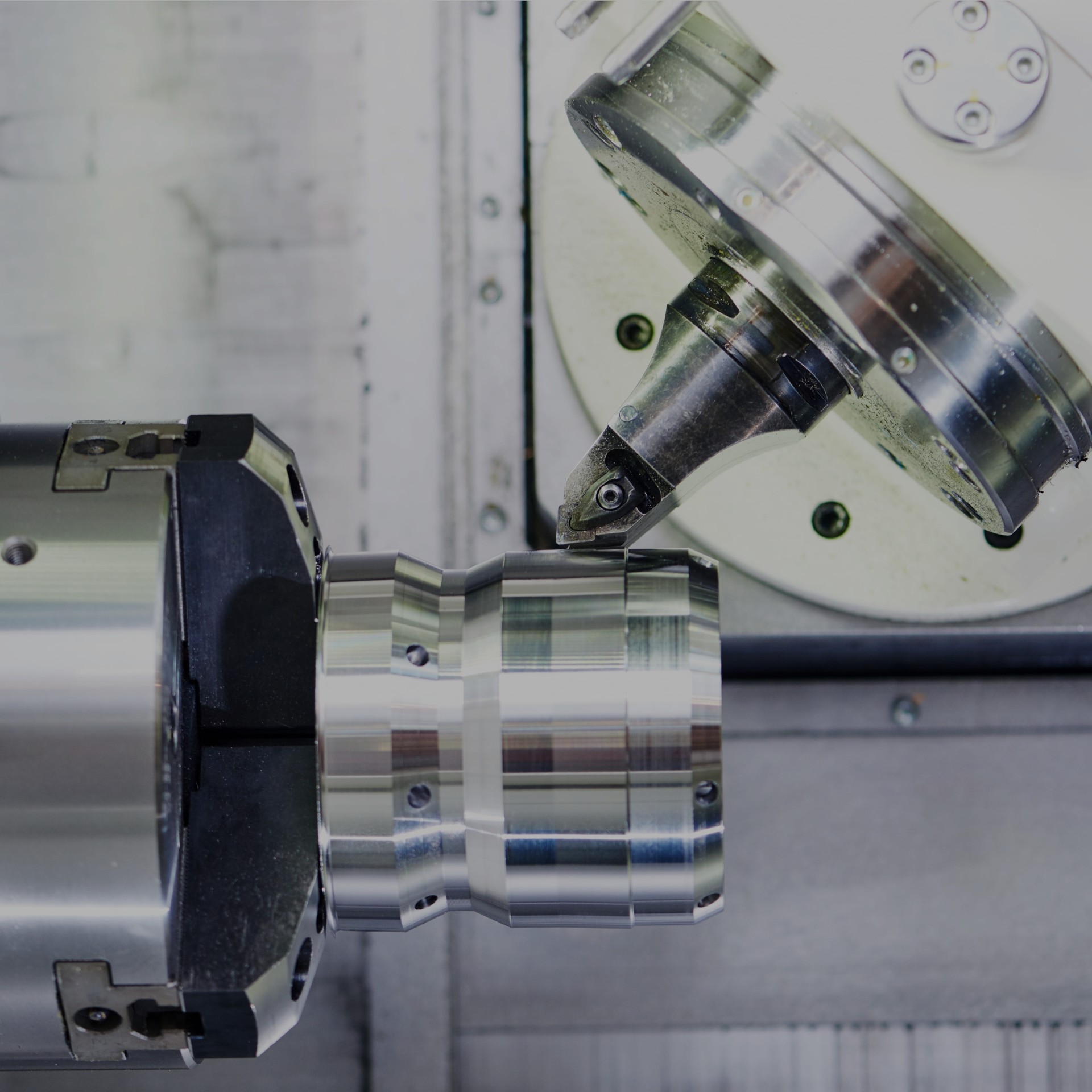

CNC machining is a manufacturing process that involves the use of computerized machines to produce parts and components. It is a highly technical field that requires precision and accuracy to ensure the quality of the final product. One of the key factors that contribute to the success of CNC machining is the selection of the right parameters. In this article, we will explore the three most important parameters in CNC machining, known as Pvs, and how they impact the final product. So, let’s dive in and learn more about the critical factors that make CNC machining a success.

The 3 most important Pvs in CNC machining are precision, speed, and flexibility. Precision is crucial for achieving accurate and consistent results, while speed is important for optimizing production efficiency. Flexibility allows for customization and adaptation to different manufacturing needs and requirements. These Pvs are essential for ensuring high-quality and efficient CNC machining processes.

What Are the 3 Most Important Pvs in CNC Machining?

When it comes to CNC machining, there are several factors that can impact the quality and accuracy of the final product. One of the most important considerations is the use of Pvs, or process variables. Pvs are essentially the different parameters that can be adjusted during the CNC machining process to achieve a desired outcome. Here are the three most important Pvs to consider when it comes to CNC machining.

1. Speed

Speed is one of the most important Pvs in CNC machining. The speed at which the machine is operating can impact the quality and accuracy of the final product. Generally, the faster the machine is running, the more accurate the final product will be. However, there is a limit to how fast the machine can run before the quality of the product starts to suffer. It’s important to find the right balance between speed and accuracy to ensure the best possible outcome.

One way to adjust speed is to change the feed rate of the machine. This refers to the speed at which the cutting tool moves across the material being worked on. Increasing the feed rate can speed up the process, but it can also increase the risk of errors. Decreasing the feed rate can help to reduce errors, but it will also slow down the process.

2. Depth of Cut

The depth of cut is another important Pvs in CNC machining. This refers to how deep the cutting tool is able to penetrate into the material being worked on. The depth of cut can impact the final product in several ways. For example, a deeper cut can create a smoother surface finish, but it can also increase the risk of tool breakage or other errors.

To adjust the depth of cut, the machine operator can change the Z-axis position of the cutting tool. This will allow the tool to penetrate deeper into the material being worked on. It’s important to find the right balance between depth of cut and other factors such as speed and feed rate to achieve the desired outcome.

3. Tool Diameter

The diameter of the cutting tool is another important Pvs in CNC machining. This refers to the size of the tool that is being used to cut the material. The diameter of the tool can impact the final product in several ways. For example, a larger tool can remove material more quickly, but it can also create rougher edges or other imperfections.

To adjust the tool diameter, the machine operator can select a different cutting tool with a different diameter. This will allow them to achieve the desired outcome based on the specific needs of the project.

In conclusion, when it comes to CNC machining, there are several important Pvs to consider. Speed, depth of cut, and tool diameter are three of the most important factors that can impact the quality and accuracy of the final product. By adjusting these Pvs carefully, machine operators can achieve the best possible outcome for each project.

Frequently Asked Questions

Here are some common questions about the 3 most important Pvs in CNC machining.

What are the 3 most important Pvs in CNC machining?

In CNC machining, Pvs refer to the Position, Velocity, and Acceleration of the machine. These three factors are critical to achieving accurate and efficient cuts.

The Position, or P, is the precise location of the machine tool in relation to the workpiece. The Velocity, or V, is the speed at which the machine is moving in any given direction. Finally, the Acceleration, or A, is the rate at which the machine can change direction or speed.

Why are Position, Velocity, and Acceleration important in CNC machining?

The accuracy and precision of a CNC machine are dependent on its ability to move with a high degree of accuracy and speed. Position, Velocity, and Acceleration are the three factors that determine the machine’s ability to achieve this level of accuracy and speed.

By optimizing these three factors, a CNC machine can achieve faster cycle times, higher accuracy, and better surface finish. This, in turn, leads to improved productivity and reduced costs for the manufacturer.

How do you optimize Position, Velocity, and Acceleration in CNC machining?

Optimizing Position, Velocity, and Acceleration in CNC machining involves balancing the three factors to achieve the desired results. This may involve adjusting the feed rates, spindle speeds, and tool paths to optimize the machine’s performance.

Additionally, using high-quality cutting tools, maintaining the machine properly, and using the appropriate lubricants and coolants can all help to improve the machine’s performance and optimize the Pvs.

What are the benefits of optimizing Position, Velocity, and Acceleration in CNC machining?

By optimizing the Pvs in CNC machining, manufacturers can achieve faster cycle times, higher accuracy, and better surface finish. This can lead to improved productivity, reduced costs, and a better overall quality of the finished product.

In addition, optimizing the Pvs can also extend the life of the machine, reduce wear and tear on the cutting tools, and improve the safety of the machining process by reducing the likelihood of errors or accidents.

What are some common challenges in optimizing Position, Velocity, and Acceleration in CNC machining?

One of the biggest challenges in optimizing the Pvs in CNC machining is finding the right balance between speed and accuracy. Increasing the speed of the machine can help to improve productivity, but it can also lead to decreased accuracy and a poorer surface finish.

Additionally, the complexity of the machining process and the materials being cut can also impact the optimization of the Pvs. For example, cutting harder materials such as titanium or stainless steel may require slower speeds and more precise positioning to achieve the desired results.

In conclusion, understanding the three most important parameters in CNC machining can make a significant difference in the precision and quality of your final product. By mastering the concepts of speed, feed rate, and depth of cut, you can optimize your machining process and achieve outstanding results.

Firstly, speed is an essential parameter that directly affects the cutting tool’s performance. A higher speed can increase material removal rates, but it can also cause excessive tool wear and heat buildup. Therefore, finding the optimal speed for your specific material and tool is crucial.

Secondly, feed rate determines how fast the cutting tool moves along the workpiece’s surface. A proper feed rate can result in improved surface finish and reduced tool wear. However, using an incorrect feed rate can lead to tool breakage or poor surface quality.

Thirdly, depth of cut refers to the amount of material the cutting tool removes in a single pass. It’s essential to select the appropriate depth of cut to avoid tool overload and ensure efficient material removal.

In summary, mastering the three Pvs of CNC machining can help you produce high-quality products with precision and accuracy. Taking the time to optimize these parameters will ultimately save you time and money in the long run.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com