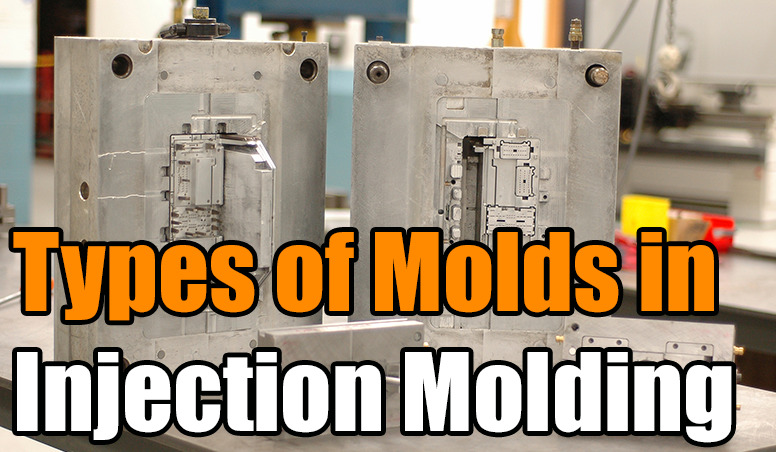

Injection molding is a manufacturing process that involves injecting molten material into a mold cavity to form a specific shape. The process is used to create a wide range of products, from toys and consumer goods to medical equipment and automotive parts. However, there are different types of injection molds, and each is designed for specific purposes.

Understanding the types of injection molds is essential for anyone looking to produce high-quality products efficiently. In this article, we will explore the different types of injection molds and their unique features, helping you select the most suitable option for your manufacturing needs.

Understanding the Different Types of Injection Mold

When it comes to manufacturing plastic parts, injection molding is a common process used by many industries. This manufacturing technique is used to produce a wide range of plastic products, from small toys to large automotive parts. Whether you’re new to the field or an experienced professional, it’s essential to understand the different types of injection molds available to choose the right one for your project. In this article, we’ll cover the various types of injection molds, how they work, and their benefits.

Cold Runner Injection Mold

A cold runner injection mold is the most basic type of injection mold. It works by using a sprue, which is a channel that delivers molten plastic to the mold cavity. The sprue is attached to the runner system, which is a network of channels that distribute the plastic throughout the mold. Once the plastic solidifies, the runner and sprue are removed, leaving the final product.

This type of injection mold is ideal for simple parts with no complex designs. It’s also the most cost-effective method, making it a popular choice for small-scale production. However, it generates more waste material than other types of injection molds.

Hot Runner Injection Mold

A hot runner injection mold works similar to a cold runner injection mold, but the runner system is heated to keep the plastic molten. This eliminates the need for a sprue, reducing waste material and improving cycle time.

Hot runner injection molds are the preferred choice for high-volume production and complex parts that require precision. They also offer better control over the flow and temperature of the plastic, resulting in a more consistent product.

Three-Plate Injection Mold

A three-plate injection mold is a more complex mold that uses three plates to separate the runner system from the mold cavity. This type of mold allows for a more intricate design and can produce parts with multiple gates.

This injection mold is ideal for parts that require different materials or colors in different sections. It’s also useful for parts that require multiple gates or parting lines. The three-plate injection mold is more expensive than the cold and hot runner molds, but it offers greater design flexibility and reduces cycle time.

Stack Mold

A stack mold is a type of injection mold that uses two or more molds to produce multiple parts simultaneously. This type of mold can produce a high volume of parts quickly, making it an ideal choice for large-scale production.

Stack molds are also useful for creating multi-material or multi-colored parts. They’re more expensive than other types of injection molds, but the increased productivity and efficiency make it a worthwhile investment.

Insert Mold

An insert mold is a type of injection mold that uses pre-formed metal inserts that are placed in the mold before the plastic is injected. This allows for the creation of parts with metal components or threaded inserts.

Insert molds are ideal for creating parts that require additional strength or durability. They’re also useful for parts that require threaded inserts or metal components. However, they’re more expensive than other types of injection molds, and the process can be more time-consuming.

Multicavity Mold

A multicavity mold is a type of injection mold that produces multiple parts with a single injection. This type of mold is useful for high-volume production of simple parts.

Multicavity molds can produce up to 100 parts in a single cycle, reducing cycle time and increasing productivity. However, they’re not suitable for complex parts or parts that require different materials or colors.

Family Mold

A family mold is a type of injection mold that produces multiple parts with different shapes and sizes. This type of mold is useful for creating parts that are related but have different functions.

Family molds are efficient and cost-effective, as they produce multiple parts in a single cycle. They’re also useful for creating parts with different sizes or shapes, reducing the need for multiple molds.

Co-injection Mold

A co-injection mold is a type of injection mold that uses two or more materials to create a single part. This type of mold is useful for creating parts with different colors or materials that require a specific finish or texture.

Co-injection molds are also useful for creating parts with a core and outer layer, reducing the need for additional assembly steps. They’re more expensive than other types of injection molds, but the added functionality makes it a worthwhile investment.

Bi-injection Mold

A bi-injection mold is a type of injection mold that uses two materials to create a part with two colors or materials. This type of mold is useful for creating parts with a specific design or function that requires two different materials.

Bi-injection molds are more expensive than other types of injection molds, but they offer greater design flexibility and reduce the need for additional assembly steps.

Multishot Mold

A multishot mold is a type of injection mold that uses two or more materials to create a part with different properties. This type of mold is useful for creating parts with varying hardness or flexibility.

Multishot molds are more expensive than other types of injection molds, but they offer greater design flexibility and reduce the need for additional assembly steps. They’re also useful for creating parts with multiple colors or materials.

In conclusion, understanding the different types of injection molds available is crucial for any manufacturing process. By choosing the right type of mold, you can improve efficiency, reduce waste, and create high-quality products. Each type of injection mold has its advantages and disadvantages, and it’s essential to weigh these factors before making a decision. By considering factors such as part complexity, production volume, and materials, you can choose the best mold for your project.

Frequently Asked Questions

Here are some common questions about the types of injection mold:

What is a hot runner injection mold?

A hot runner injection mold is a type of injection mold that uses a heated runner system to keep the plastic in the mold at a consistent temperature. The heated runner system is made up of a series of channels that distribute the plastic to the different cavities in the mold. This type of mold is often used for high-volume production runs because it eliminates the need for the plastic to be reheated each time a new part is created.

The benefits of a hot runner injection mold include faster cycle times, reduced waste, and improved part quality. However, this type of mold can be more expensive to purchase and maintain compared to a cold runner mold.

What is a cold runner injection mold?

A cold runner injection mold is a type of injection mold that uses a runner system that is not heated. The plastic is injected into the mold through the runner system, which leads to the different cavities in the mold. After the plastic has solidified, the runner system is ejected along with the part, creating waste material.

The benefits of a cold runner injection mold include lower cost and simpler maintenance compared to a hot runner mold. However, this type of mold can result in longer cycle times and more waste material.

What is an unscrewing injection mold?

An unscrewing injection mold is a type of injection mold that uses a rotating core to remove the part from the mold. This type of mold is often used for parts that have threads or other complex geometries that cannot be ejected from the mold in a straight line. The rotating core is operated by a hydraulic or electric motor and can be programmed to rotate at different speeds.

The benefits of an unscrewing injection mold include the ability to create complex parts and the elimination of the need for manual removal of the part from the mold. However, this type of mold can be more expensive and require more maintenance compared to other types of molds.

What is a two-shot injection mold?

A two-shot injection mold is a type of injection mold that creates a part using two different materials or colors. The first material is injected into the mold, followed by the second material, which is injected into the first material while it is still in the mold. This type of mold is often used for parts that require a soft-touch grip or multiple colors.

The benefits of a two-shot injection mold include the ability to create more complex parts and the elimination of the need for secondary assembly operations. However, this type of mold can be more expensive and require more setup time compared to a single-shot mold.

What is an insert injection mold?

An insert injection mold is a type of injection mold that includes metal or plastic inserts in the mold. The plastic is injected around the inserts, creating a part that includes the inserts. This type of mold is often used for parts that require metal or plastic inserts for strength or functionality.

The benefits of an insert injection mold include the ability to create parts with metal or plastic inserts and the elimination of the need for secondary assembly operations. However, this type of mold can be more expensive and require more setup time compared to a standard injection mold.

In conclusion, injection molding is a versatile manufacturing process that has a wide range of applications across various industries. There are several types of injection molds, each with its unique advantages and disadvantages. Understanding the different types of injection molds is crucial in choosing the best option for your manufacturing needs.

The three main types of injection molds are cold runner molds, hot runner molds, and insulated runner molds. Cold runner molds are the most common type and are ideal for simple parts with a low volume production. Hot runner molds are more complex and are typically used for high volume production of complex parts. Insulated runner molds are a hybrid of cold and hot runner molds and are ideal for parts that require both precision and flexibility.

In conclusion, choosing the right type of injection mold is essential for achieving the desired results in your manufacturing process. Consider the nature of your production needs, the complexity of your parts, and the volume of production when selecting the most appropriate type of injection mold for your project.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com