Table of Contents

Are you in the market for a CNC grinder but unsure of the cost? It’s a common question for those in the manufacturing industry. The truth is, the cost of a CNC grinder can vary greatly depending on several factors. In this article, we’ll explore those factors and give you a better idea of what you can expect to pay for a CNC grinder.

From the size of the machine to the complexity of the software, there are many factors that can influence the cost of a CNC grinder. But don’t worry, we’ll break it down for you. By the end of this article, you’ll have a better understanding of what to expect and be better equipped to make an informed decision when shopping for a CNC grinder. So, let’s dive in!

What Does a CNC Grinder Cost?

CNC grinders are widely used in the manufacturing industry for precision grinding of various materials. They are preferred over traditional grinders due to their higher accuracy and efficiency. However, the cost of a CNC grinder varies depending on several factors. In this article, we will explore the different factors that affect the cost of a CNC grinder.

Factors Affecting the Cost of a CNC Grinder

1. Size and Capacity:

The size and capacity of a CNC grinder are significant factors in determining its cost. Larger grinders with higher capacity are more expensive than smaller ones. The size of the grinder is determined by the grinding wheel’s diameter and the distance between the wheel and the workpiece. The capacity of the grinder is determined by the maximum weight and size of the workpiece that can be accommodated by the machine.

2. Automation:

CNC grinders with higher levels of automation are more expensive than those with lower levels of automation. Automation can include automatic tool changers, automatic workpiece positioning, and automatic grinding wheel dressing. The level of automation depends on the specific requirements of the manufacturing process.

3. Precision and Accuracy:

CNC grinders that offer higher precision and accuracy are more expensive than those that offer lower precision and accuracy. Factors that affect precision and accuracy include the quality of the grinding wheel, the rigidity of the machine’s structure, and the accuracy of the positioning system. Higher precision and accuracy are necessary for grinding complex shapes and achieving tight tolerances.

4. Brand and Manufacturer:

The brand and manufacturer of a CNC grinder can also affect its cost. Well-known brands that have a reputation for quality and reliability are generally more expensive than lesser-known brands. Similarly, manufacturers that have a long history of producing high-quality machines are usually more expensive than new manufacturers.

5. Additional Features:

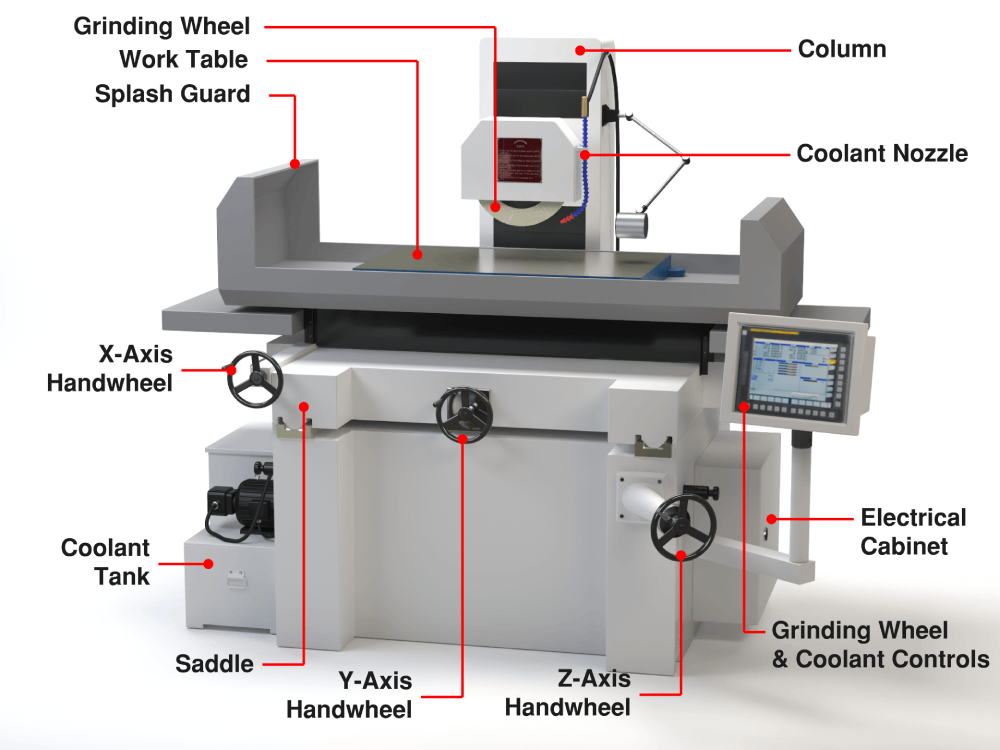

CNC grinders can come with additional features that increase their cost. These features can include coolant systems, filtration systems, and digital readouts. The cost of these features depends on the specific requirements of the manufacturing process.

Benefits of Using a CNC Grinder

1. Higher Accuracy:

CNC grinders offer higher accuracy and precision than traditional grinders. This is because the grinding process is controlled by a computer, which ensures that the grinding wheel is in the right position and moving at the correct speed. The result is a more precise and accurate finished product.

2. Higher Efficiency:

CNC grinders are more efficient than traditional grinders because they can operate continuously without the need for manual intervention. This means that they can produce more parts in less time, which increases overall productivity.

3. Consistency:

CNC grinders produce consistent results because they are programmed to follow the same process every time. This means that the finished product is always the same, regardless of who operates the machine.

CNC Grinder Vs. Traditional Grinder

1. Accuracy:

CNC grinders offer higher accuracy and precision than traditional grinders. This is because the grinding process is controlled by a computer, which ensures that the grinding wheel is in the right position and moving at the correct speed. Traditional grinders rely on the operator’s skill, which can lead to variations in the finished product.

2. Efficiency:

CNC grinders are more efficient than traditional grinders because they can operate continuously without the need for manual intervention. Traditional grinders require manual intervention to adjust the grinding wheel’s position and speed, which slows down the process and reduces efficiency.

3. Consistency:

CNC grinders produce consistent results because they are programmed to follow the same process every time. Traditional grinders rely on the operator’s skill, which can lead to variations in the finished product.

CNC Grinder Cost Comparison

Below is a table comparing the cost of different types of CNC grinders:

| Type of CNC Grinder | Cost (USD) |

|---|---|

| Surface Grinder | 10,000 – 50,000 |

| Cylindrical Grinder | 50,000 – 150,000 |

| Tool and Cutter Grinder | 50,000 – 200,000 |

As you can see from the table, the cost of a CNC grinder depends on the type of grinder and its capacity. Surface grinders are the least expensive, while tool and cutter grinders are the most expensive. The cost also depends on the specific requirements of the manufacturing process.

Conclusion

Overall, the cost of a CNC grinder depends on several factors, including the size and capacity of the machine, the level of automation, the precision and accuracy, the brand and manufacturer, and any additional features. While CNC grinders are more expensive than traditional grinders, they offer higher accuracy, efficiency, and consistency, which can lead to significant cost savings in the long run.

Frequently Asked Questions

If you’re looking to purchase a CNC grinder, you’re probably wondering how much it will cost. Below are some frequently asked questions and answers about the cost of CNC grinders.

What is a CNC grinder?

A CNC grinder is a type of machine tool used to grind and shape metal or other materials. It is controlled by a computer program that tells the machine how to move and shape the material. CNC grinders are used in a variety of industries, including aerospace, automotive, and medical manufacturing.

CNC grinders come in a variety of sizes and types, from small tabletop machines to large industrial machines. The cost of a CNC grinder depends on its size and capabilities.

How much does a CNC grinder cost?

The cost of a CNC grinder can vary greatly depending on the size and capabilities of the machine. Small tabletop machines can cost as little as a few thousand dollars, while large industrial machines can cost hundreds of thousands of dollars.

Other factors that can affect the cost of a CNC grinder include the manufacturer, the level of automation, and the number of axes. It’s important to do your research and choose a machine that meets your specific needs and budget.

What are the benefits of a CNC grinder?

CNC grinders offer several benefits over traditional grinding machines. They are more precise and accurate, allowing for tighter tolerances and better surface finishes. They also offer increased productivity, as they can run continuously without the need for operator intervention.

Additionally, CNC grinders can be programmed to produce complex shapes and contours, making them ideal for producing parts with intricate geometries. This level of flexibility and precision can help reduce waste and improve overall product quality.

How do I choose the right CNC grinder for my needs?

Choosing the right CNC grinder depends on several factors, including the size and complexity of the parts you need to produce, your budget, and your production volume. You should also consider the level of automation and the number of axes you need.

It’s important to do your research and talk to manufacturers and other industry experts to determine the best machine for your specific needs. You should also factor in the cost of maintenance, training, and support when making your decision.

What is the cost of maintenance for a CNC grinder?

The cost of maintenance for a CNC grinder can vary depending on the type and size of the machine. Generally, smaller machines require less maintenance than larger machines.

Routine maintenance tasks for a CNC grinder may include cleaning, lubrication, and replacement of worn parts. It’s important to follow the manufacturer’s recommended maintenance schedule to ensure the machine continues to operate at peak efficiency. The cost of maintenance should be factored into the overall cost of owning and operating a CNC grinder.

In conclusion, the cost of a CNC grinder can vary depending on several factors such as the type of grinder, the level of automation, and the brand. However, it is safe to say that purchasing a CNC grinder is a significant investment for any business, but it can also provide long-term benefits in terms of increased productivity and efficiency.

When considering the cost of a CNC grinder, it is essential to take into account not only the initial purchase price but also the ongoing costs such as maintenance, repairs, and operator training. It’s important to choose a reputable supplier who can provide after-sales support to ensure that your investment is protected.

Lastly, it’s worth noting that the cost of a CNC grinder should not be the sole determining factor when making a purchasing decision. Other factors such as the quality of the machine, its capabilities, and the supplier’s reputation should also be taken into consideration. Ultimately, investing in a quality CNC grinder can help businesses to stay competitive and achieve success in the long run.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com