Table of Contents

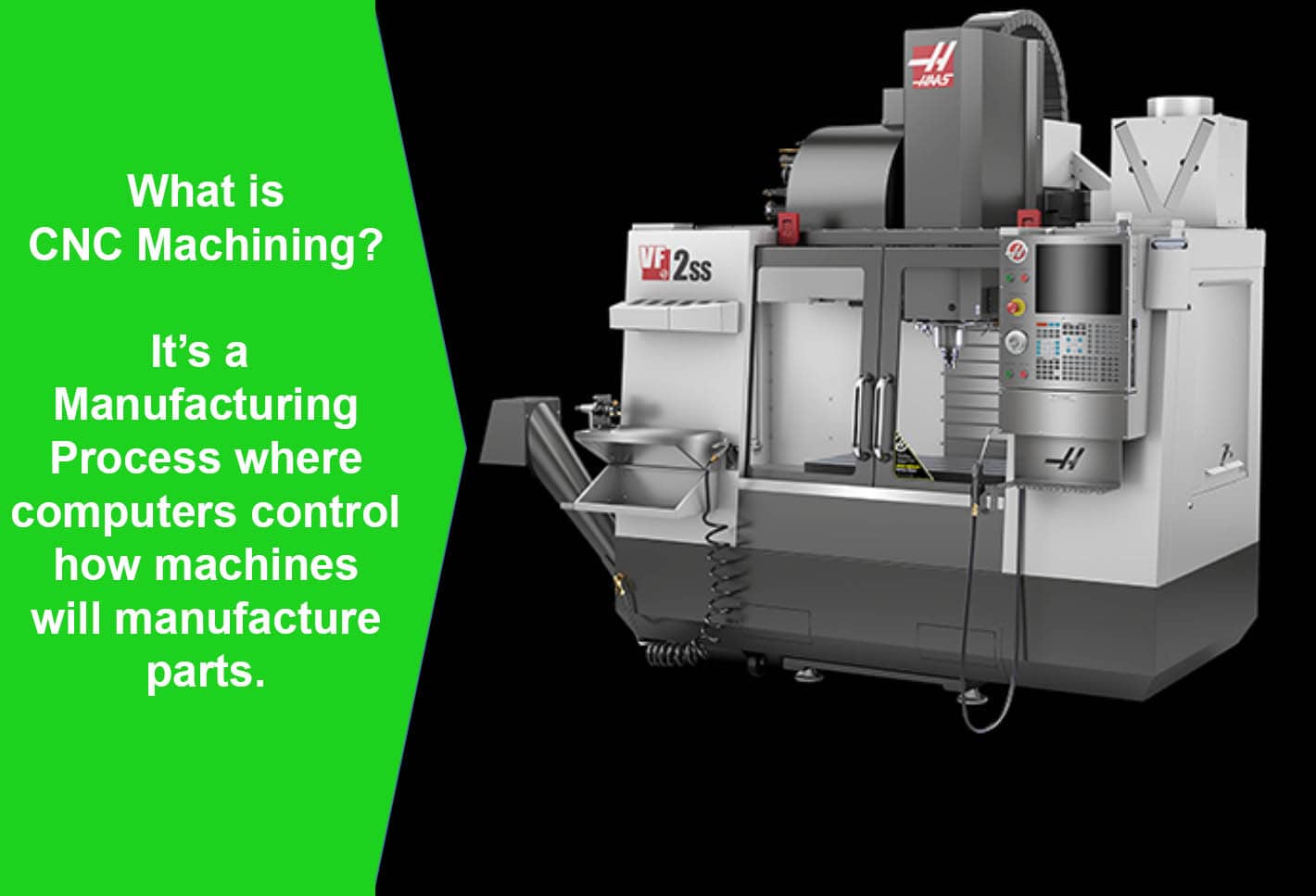

CNC machining is a term that you may have heard floating around the manufacturing world. But what exactly does it stand for and what does it entail? CNC stands for Computer Numerical Control, which means that machines are programmed to perform specific tasks with high precision and accuracy. In this article, we’ll dive deeper into the world of CNC machining and explore its various applications and benefits.

This technology has revolutionized the way that manufacturing is done, making it faster, more efficient, and more accurate than ever before. From creating intricate parts for aerospace components to producing custom-made medical devices, CNC machining has become an indispensable tool in a wide range of industries. So, let’s take a closer look at what CNC machining is and why it’s so important in today’s manufacturing landscape.

What Does CNC Machining Stand for?

CNC machining stands for Computer Numerical Control Machining. It is a manufacturing process that utilizes computer software to control the movement of machine tools.

How Does CNC Machining Work?

CNC machining involves the use of computer software to program the movements of machine tools. The machine tool then follows the programmed instructions to create precise shapes and sizes.

The process begins with a design file that is created using computer-aided design (CAD) software. The design file is then converted into a format that can be read by the CNC machine.

Once the program is loaded onto the CNC machine, the operator selects the appropriate tools and materials. The machine then follows the programmed instructions to create the desired shape.

Types of CNC Machines

There are several types of CNC machines, each with its own unique capabilities. Some of the most common types include:

- Mill

- Lathe

- Router

- Plasma cutter

- 3D printer

Each type of machine has its own specific applications and benefits. For example, a lathe is often used for creating cylindrical shapes, while a router is ideal for cutting intricate designs.

Benefits of CNC Machining

CNC machining offers a number of benefits over traditional manufacturing methods. Some of the key benefits include:

- Precision: CNC machines can create parts with extremely high levels of precision.

- Efficiency: CNC machines can work continuously without the need for breaks or rest.

- Flexibility: CNC machines can be programmed to create a wide range of parts and products.

- Consistency: CNC machines can produce identical parts with a high degree of consistency.

CNC Machining Vs Traditional Machining

CNC machining is often compared to traditional machining methods, such as manual milling and turning. While both methods can produce high-quality parts, there are some key differences between them.

Traditional machining requires skilled operators to manually control the movement of the machine tools. This can be time-consuming and can lead to errors.

CNC machining, on the other hand, utilizes computer software to control the movement of the machine tools. This results in a more efficient and precise process.

Industries That Use CNC Machining

CNC machining is used in a wide range of industries, including:

- Aerospace

- Automotive

- Medical

- Construction

- Electronics

Each industry has its own unique applications for CNC machining. For example, the aerospace industry often uses CNC machining to create complex parts for aircraft and spacecraft.

The Future of CNC Machining

As technology continues to evolve, so too does the world of CNC machining. Some of the key advancements in recent years include:

- Increased automation

- Improved software

- Integration with other technologies, such as additive manufacturing

These advancements are helping to make CNC machining faster, more efficient, and more accessible than ever before.

Conclusion

CNC machining is a vital process in modern manufacturing. By utilizing computer software to control the movement of machine tools, CNC machining offers a number of benefits over traditional methods. From aerospace to electronics, CNC machining is used in a wide range of industries to create precise and complex parts.

Frequently Asked Questions

Here are some commonly asked questions about CNC machining and their answers.

What Does CNC Machining Stand for?

CNC stands for Computer Numerical Control. CNC machining is a manufacturing process that uses pre-programmed computer software to control the movements of machinery and tools. This technology is used to create a wide range of complex parts and components with high accuracy and precision.

CNC machines can produce parts from a variety of materials, including metals, plastics, and composites. These machines are widely used in industries such as aerospace, automotive, medical, and electronics manufacturing. CNC machining offers many advantages over conventional machining methods, including increased efficiency, accuracy, and consistency.

How Does CNC Machining Work?

CNC machining works by using computer software to control the movements of machine tools. This software generates a set of instructions, or “code,” that tells the machine how to move and what actions to perform. The machine then uses these instructions to cut, shape, or drill the material being worked on.

CNC machines are highly automated and can perform complex operations with great precision. They can also work continuously for long periods of time, which makes them ideal for mass production. CNC machining involves several steps, including design, programming, setup, and operation.

What Are the Benefits of CNC Machining?

CNC machining offers many benefits over traditional machining methods. One of the biggest advantages is increased efficiency. CNC machines can work much faster than human operators and can run continuously for long periods of time. This makes them ideal for high-volume production runs.

CNC machining also offers greater accuracy and consistency. Because the machines are pre-programmed, they can perform the same operations over and over again with the same level of precision. This means that the parts they produce are more reliable and consistent than those produced by manual machining methods.

What Are the Different Types of CNC Machines?

There are many different types of CNC machines, each designed for specific applications. Some common types of CNC machines include milling machines, lathes, drills, routers, and plasma cutters. Each of these machines is designed to perform specific types of operations and can be used to create a wide range of parts and components.

CNC machines can also be classified based on their level of automation. Some machines are fully automated and require little or no human intervention, while others are semi-automated and require some level of operator input. The type of machine used will depend on the specific needs of the application.

What Are the Limitations of CNC Machining?

While CNC machining offers many advantages, there are also some limitations to the technology. One of the biggest limitations is cost. CNC machines can be expensive to purchase and maintain, which can be a barrier for small businesses and startups.

Another limitation is complexity. While CNC machines are highly automated, they still require skilled operators to set up and program them. This can be a challenge for some companies that do not have the resources or expertise to operate these machines. Finally, CNC machines are not suitable for all types of materials and applications. Some materials may be too hard or brittle to machine effectively, while others may require specialized equipment or processes.

In conclusion, CNC machining is a critical process used in manufacturing, engineering, and other industries. It stands for “Computer Numerical Control” and involves the use of computers to control tools and machines for precision cutting and shaping of materials. This technology has revolutionized the manufacturing industry, allowing for faster production times, greater accuracy, and cost-effectiveness.

One of the most significant advantages of CNC machining is its ability to produce complex shapes and designs with high precision. This technology has opened up new possibilities for product design and innovation, enabling manufacturers to create unique and intricate parts that were previously impossible to produce.

Moreover, CNC machining has greatly increased efficiency in manufacturing processes. With the use of computer programs, manufacturers can easily design and modify parts, reducing the time and cost of production. The automation of CNC machining has also eliminated human error, ensuring consistent and accurate results every time.

In summary, CNC machining is a game-changer in the manufacturing industry. Its precision, efficiency, and versatility have made it an indispensable tool for manufacturers worldwide. As technology continues to advance, we can expect even greater advancements in CNC machining, further enhancing its capabilities and revolutionizing the manufacturing process.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com