Table of Contents

- What is 2.5D CNC?

- How does 2.5D CNC work?

- What are the benefits of 2.5D CNC?

- What are the Vs of 2.5D CNC?

- What are the applications of 2.5D CNC?

- What are the types of materials used in 2.5D CNC?

- What are the advantages of using 2.5D CNC over manual machining?

- What are the disadvantages of using 2.5D CNC?

- What are the best practices for 2.5D CNC machining?

- What are the future trends of 2.5D CNC?

- Frequently Asked Questions

Are you familiar with CNC machining? If you are, then you might have heard of the term “2.5D CNC”. But what is it exactly?

In simple terms, 2.5D CNC is a type of CNC machining that involves cutting out flat or 2D objects with added depth or 3D features. It’s a popular technique used in many industries, including automotive, aerospace, and electronics. In this article, we’ll delve deeper into what 2.5D CNC is, how it works, and its advantages. So, let’s get started!

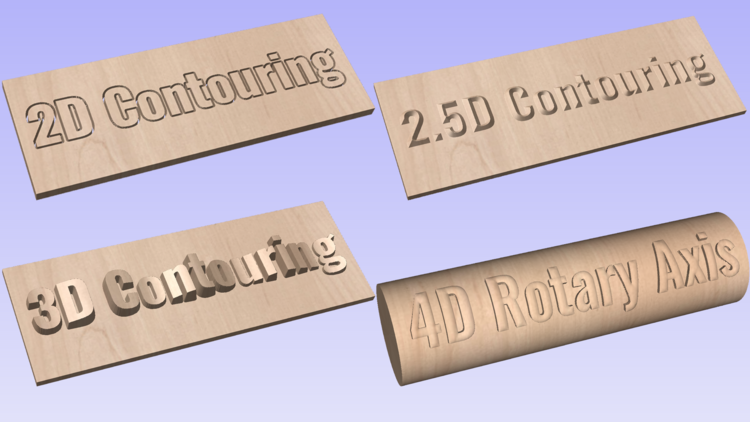

2.5D CNC refers to a type of machining that involves cutting parts with a three-axis milling machine, but with the third axis limited to moving in a vertical direction. This means that the machine can create complex shapes and features, but cannot produce true 3D parts. 2.5D CNC is commonly used for creating parts with features on multiple planes, such as circuit boards, nameplates, and front panels.

What is 2.5D CNC?

2.5D CNC or two-and-a-half-dimensional CNC machining is a manufacturing process that involves the use of computer numerical control (CNC) machines to create three-dimensional objects with flat surfaces. Unlike traditional three-dimensional CNC machining, which uses a rotating cutting tool to shape a material block into a desired shape, 2.5D CNC machining uses a combination of cutting, drilling, and milling to create a flat surface with a three-dimensional shape.

How does 2.5D CNC work?

The 2.5D CNC machining process begins with a digital model of the desired object, which is created using computer-aided design (CAD) software. This model is then loaded into the CNC machine’s software, which generates a series of tool paths that the machine will follow to create the final object.

The CNC machine consists of a worktable, a spindle, and a set of cutting tools. The worktable holds the material being machined in place, while the spindle rotates at high speeds to cut and drill the material. The cutting tools are mounted on the spindle and move in the X, Y, and Z axes to shape the material.

What are the benefits of 2.5D CNC?

2.5D CNC machining offers several benefits over traditional machining methods. One of the main advantages is its ability to create complex shapes and geometries with high precision and accuracy. This makes it ideal for prototyping and small-scale production runs.

Another benefit of 2.5D CNC machining is its speed and efficiency. Because the process is automated, it can be completed much faster than traditional machining methods, which can save time and reduce costs.

What are the Vs of 2.5D CNC?

Compared to other CNC machining methods, 2.5D CNC has some distinct advantages and disadvantages. One of the main advantages is its ability to create complex shapes and geometries with high precision and accuracy.

On the downside, 2.5D CNC is not suitable for creating fully three-dimensional objects with curved surfaces. This limits its application to certain types of objects and makes it less versatile than other CNC machining methods.

What are the applications of 2.5D CNC?

2.5D CNC machining has a wide range of applications in various industries, including aerospace, automotive, electronics, and medical devices. Some of the most common applications include the creation of printed circuit boards, molds and dies, and precision parts for machinery.

In addition, 2.5D CNC machining is often used for prototyping and small-scale production runs, as it allows for quick and cost-effective production of complex parts.

What are the types of materials used in 2.5D CNC?

2.5D CNC machining can be performed on a variety of materials, including metals, plastics, and composites. Some of the most common materials used in 2.5D CNC include aluminum, steel, brass, copper, and titanium.

In addition, 2.5D CNC machining can be used on a range of plastics, such as polycarbonate, acrylic, and nylon, as well as composites like carbon fiber and fiberglass.

What are the advantages of using 2.5D CNC over manual machining?

2.5D CNC machining offers several advantages over manual machining methods. One of the main advantages is its precision and accuracy, which allows for the creation of complex shapes and geometries with high levels of detail.

In addition, 2.5D CNC machining is much faster than manual machining, which can save time and reduce costs. Finally, 2.5D CNC machining is more consistent and repeatable than manual machining, which ensures that every part produced is of high quality.

What are the disadvantages of using 2.5D CNC?

Despite its many advantages, 2.5D CNC machining does have some drawbacks. One of the main disadvantages is its limited ability to create fully three-dimensional objects with curved surfaces, which can limit its versatility.

In addition, 2.5D CNC machining can be more expensive than manual machining, particularly for small-scale production runs. Finally, the complexity of the software and equipment required for 2.5D CNC machining can make it more difficult to learn and operate than manual machining.

What are the best practices for 2.5D CNC machining?

To achieve the best results with 2.5D CNC machining, it is important to follow some best practices. These include selecting the right cutting tools and parameters for the material being machined, using proper fixturing and clamping techniques to hold the material in place, and regularly checking the machine for accuracy and calibration.

In addition, it is important to use appropriate cutting strategies and tool paths to minimize tool wear and maintain high levels of precision and accuracy. Finally, it is important to choose the right software and equipment for the job, and to invest in regular training and education to stay up-to-date with the latest techniques and technologies in 2.5D CNC machining.

What are the future trends of 2.5D CNC?

As with all manufacturing technologies, 2.5D CNC machining is constantly evolving and improving. Some of the future trends in 2.5D CNC machining include the development of new and more advanced cutting tools and materials, the integration of artificial intelligence and machine learning into the machining process, and the continued expansion of the range of materials that can be machined using 2.5D CNC.

In addition, there is a growing trend towards the use of 2.5D CNC in combination with other manufacturing processes, such as 3D printing and injection molding, to create more complex and innovative products. Overall, the future of 2.5D CNC machining looks bright, with new and exciting developments on the horizon.

Frequently Asked Questions

What is 2.5D CNC?

2.5D CNC is a type of machining process that involves cutting out shapes and designs from a flat surface with the help of a computer numerical control (CNC) machine. The term “2.5D” refers to the fact that the process only involves two axes of motion (x and y), but can create objects with a third dimension (z) by using multiple layers of material.

2.5D CNC is commonly used in industries such as woodworking, metalworking, and printing. It is an efficient and precise way to create complex designs with a high level of accuracy and repeatability.

How does 2.5D CNC work?

2.5D CNC works by using a computer program to control the movement of a cutting tool across a flat surface. The program specifies the exact path that the tool should follow, as well as the depth and speed of the cuts. The machine uses this information to carve out the design from the material, layer by layer.

The process begins with a digital file of the design, which is loaded into the CNC machine. The machine then uses its cutting tool to remove material from the surface of the workpiece, following the path specified by the program. This process continues until the design is complete.

What are the benefits of using 2.5D CNC?

There are several benefits to using 2.5D CNC for machining. One of the main advantages is the precision and accuracy that the process provides. Because the machine is controlled by a computer program, it can make very precise cuts with a high level of repeatability, ensuring that each piece is identical to the next.

Another benefit of 2.5D CNC is that it can be used to create complex designs that would be difficult or impossible to achieve using traditional machining methods. The process is also very efficient, as it can produce large numbers of identical pieces in a relatively short amount of time.

What materials can be used with 2.5D CNC?

2.5D CNC can be used with a wide range of materials, including wood, metal, plastics, and composites. The specific material used will depend on the application and the requirements of the design. For example, wood is often used in furniture making, while metal is commonly used in aerospace and automotive applications.

The thickness of the material can also vary, depending on the requirements of the design. Thicker materials may require multiple passes with the cutting tool, while thinner materials may only require a single pass.

What are some common applications of 2.5D CNC?

2.5D CNC is used in a wide range of industries and applications, including woodworking, metalworking, printing, and prototyping. In woodworking, it is often used to create furniture, cabinetry, and decorative pieces. In metalworking, it is used to create precision parts for aerospace, automotive, and medical applications.

In printing, 2.5D CNC can be used to create intricate designs and patterns on paper, cardboard, and other materials. In prototyping, it is used to quickly and efficiently create models and prototypes of new products, allowing designers to test and refine their designs before going into full production.

In conclusion, 2.5D CNC is a technology that has revolutionized the world of machining by allowing for the creation of complex 2D and 3D parts with high precision and accuracy. With its ability to combine the benefits of 2D and 3D machining, 2.5D CNC has become an essential tool in many industries, including aerospace, automotive, and medical.

Moreover, this technology has increased the speed and efficiency of the manufacturing process, allowing for faster production times and improved product quality. In addition, 2.5D CNC has also reduced the need for manual labor, making it a cost-effective solution for many businesses.

Overall, 2.5D CNC is a crucial technology that has transformed the way we approach machining. With its ability to create complex parts with high accuracy and efficiency, it has become an indispensable tool for businesses looking to improve their manufacturing processes and stay ahead of the competition.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com