Table of Contents

CNC routers are computer-controlled machines that can cut and shape various materials with precision and accuracy. They are widely used in the manufacturing industry for creating intricate designs, prototypes, and finished products. But what exactly is a CNC router, and how does it work?

In simple terms, a CNC router is a cutting machine that uses a computer program to control its movements. The machine’s cutting tool moves along multiple axes, cutting and shaping the material according to the design specified in the program. In this article, we will delve deeper into the working of a CNC router and explore its various applications in different industries.

What is a CNC Router and How Does It Work?

CNC, which stands for Computer Numerical Control, is a technology used to control machinery with the help of software programs, allowing for precision cutting and shaping of materials. A CNC router, therefore, is a machine tool that uses computer numerical control to perform a variety of tasks, including cutting, drilling, carving, and engraving.

How Does a CNC Router Work?

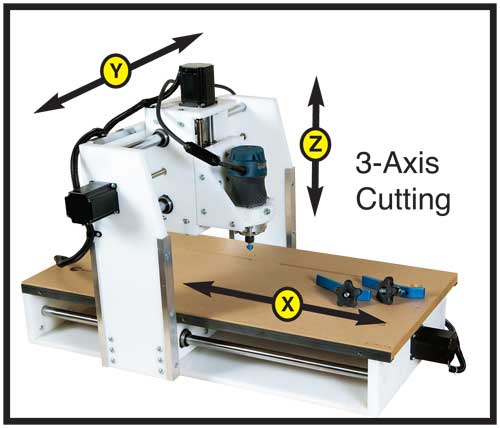

A CNC router works by taking instructions from a computer program and translating them into precise movements of a cutting tool. The cutting tool, which is attached to a spindle, moves along the X, Y, and Z axes, allowing it to cut through materials in three dimensions. The computer program, or software, controls the movements of the cutting tool, which can be a drill bit, router bit, or other cutting tool.

When using a CNC router, the material being cut is typically held in place on a bed or table that moves in the X and Y directions. The cutting tool, which is attached to a vertical spindle, moves up and down in the Z direction. This allows the cutting tool to cut through the material at various depths and angles, resulting in intricate and precise cuts.

The Components of a CNC Router

A CNC router consists of several key components that work together to perform the cutting and shaping operations. These components include:

- The control panel: This is where the operator enters the instructions for the CNC router.

- The software: This is the program that controls the movements of the cutting tool.

- The spindle: This is the motor that rotates the cutting tool.

- The cutting tool: This is the tool that actually cuts the material.

- The bed or table: This is where the material being cut is held in place.

- The motors and drives: These control the movements of the cutting tool and the bed or table.

The Benefits of Using a CNC Router

There are several benefits to using a CNC router over traditional methods of cutting and shaping materials. Some of these benefits include:

- Precision: CNC routers can make precise cuts and shapes with a high degree of accuracy.

- Speed: CNC routers can complete tasks quickly, allowing for faster production times.

- Consistency: Because the movements of the cutting tool are controlled by a computer program, the cuts and shapes produced by a CNC router are consistent and repeatable.

- Versatility: CNC routers can work with a variety of materials, including wood, plastic, metal, and composites.

- Efficiency: CNC routers can perform multiple operations on a single piece of material, reducing waste and increasing efficiency.

CNC Routers vs. Traditional Methods

When comparing CNC routers to traditional methods of cutting and shaping materials, there are several factors to consider. These include:

- Precision: CNC routers are generally more precise than traditional methods, which can result in better quality finished products.

- Speed: CNC routers can complete tasks faster than traditional methods, which can result in faster production times.

- Consistency: CNC routers produce consistent results, while traditional methods can be more prone to human error.

- Cost: CNC routers can be more expensive than traditional methods, but they can also be more efficient in the long run.

- Flexibility: Traditional methods may offer more flexibility in terms of the shapes and sizes that can be produced, but CNC routers can be programmed to produce a wide range of shapes and sizes as well.

Conclusion

CNC routers are powerful machines that offer precision, speed, consistency, and versatility in cutting and shaping a wide range of materials. While they may be more expensive than traditional methods, the benefits they offer in terms of quality, efficiency, and productivity make them a worthwhile investment for many businesses and industries. Whether you are a hobbyist or a professional, a CNC router can help you take your cutting and shaping capabilities to the next level.

Freequently Asked Questions

In this section, we will answer some common questions about CNC routers, including what they are and how they work.

What is a CNC router?

A CNC router is a computer-controlled cutting machine that is used to create a wide range of designs and shapes from various materials, such as wood, plastic, and metal. The machine uses a spinning router bit to cut into the material and create the desired design or shape. The design is first created using computer-aided design (CAD) software and then sent to the CNC router, which uses the design to guide its movements and create the finished product.

CNC routers are widely used in manufacturing and woodworking industries, as well as in hobbyist settings for creating custom designs and projects. They offer high precision and accuracy, allowing for complex and intricate designs to be created with ease.

How does a CNC router work?

A CNC router works by using a computer-controlled cutting head to move along the X, Y, and Z axes, cutting into the material to create the desired design or shape. The cutting head typically uses a spinning router bit, which can be changed out depending on the desired design and material being used.

The design is first created using CAD software, which is then exported as a G-code file. The G-code file contains the instructions for the CNC router, telling it how to move and cut into the material to create the design. The G-code file is then sent to the CNC router, which uses the instructions to guide its movements and create the finished product.

What materials can be used with a CNC router?

A CNC router can be used with a wide range of materials, including wood, plastic, metal, foam, and composite materials. The type of material used will depend on the desired design and the final product being created. Different materials may require different router bits or cutting speeds, so it is important to choose the appropriate settings for each material.

CNC routers are commonly used in woodworking and manufacturing industries, where they are used to create furniture, cabinetry, and other custom products. They are also popular in hobbyist settings, where they can be used to create custom designs and projects from a variety of materials.

What are the advantages of using a CNC router?

There are several advantages to using a CNC router, including high precision and accuracy, increased productivity, and the ability to create complex and intricate designs with ease. CNC routers can also be used to create multiple copies of the same design, making them ideal for mass production.

Additionally, CNC routers can be used with a wide range of materials, allowing for versatility and flexibility in design. They also offer a high level of safety, as the cutting head is controlled by a computer and does not require manual intervention.

What are some common applications of CNC routers?

CNC routers are used in a wide range of applications, including woodworking, manufacturing, and prototyping. They are commonly used to create furniture, cabinetry, and other custom products in the woodworking industry, as well as in the production of automotive parts, aerospace components, and other manufactured goods.

CNC routers are also popular in the prototyping industry, where they are used to create custom designs and models for product development. They offer high precision and accuracy, allowing for complex and intricate designs to be created with ease.

In conclusion, a CNC router is a powerful tool that can produce high-quality, precise cuts in a variety of materials. Its computer-controlled system allows for quick and efficient production, making it a valuable asset in industries ranging from woodworking to metalworking.

To operate a CNC router, you first need to create a design using specialized software. This design is then loaded onto the machine, and the router follows the programmed instructions to create the desired shape or cut.

Overall, the CNC router is a game-changing technology that has revolutionized the manufacturing industry. With its speed, accuracy, and versatility, it has become an essential tool for businesses looking to increase efficiency and productivity.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com