Table of Contents

CNC machines are an integral part of modern manufacturing industries. They rely on computer programming to control various cutting tools, allowing for highly precise and efficient production processes. One of the essential features of CNC machines is cutter radius compensation, which plays a crucial role in ensuring accurate and consistent results.

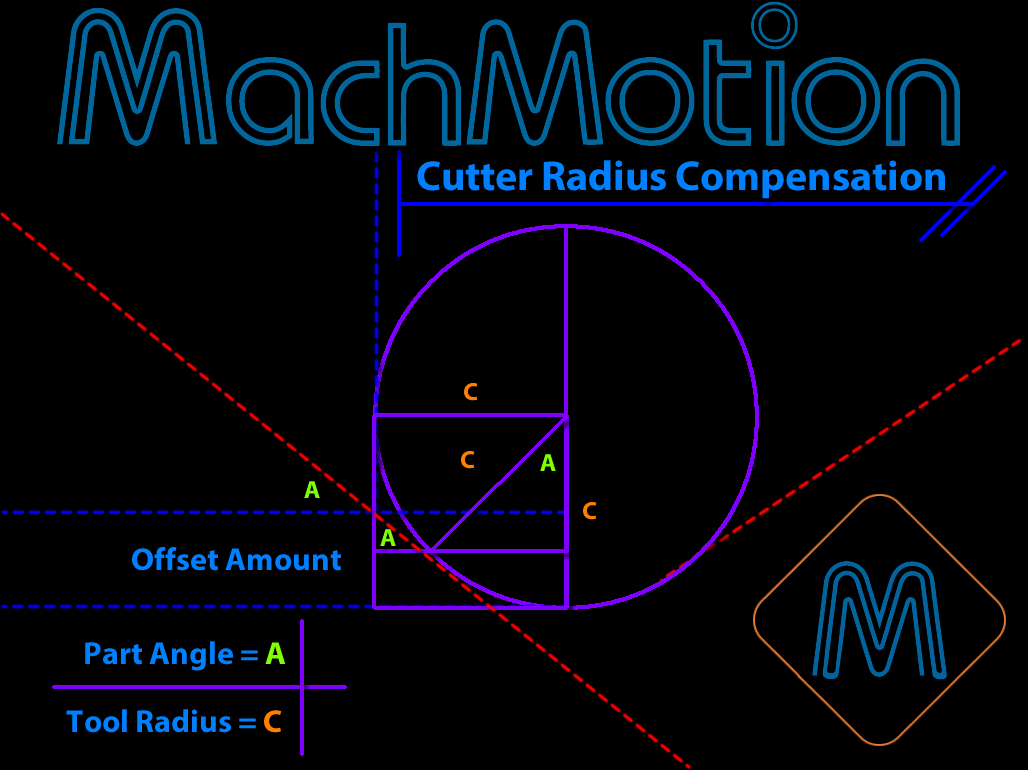

Cutter radius compensation refers to the ability of a CNC machine to adjust the cutting tool’s position to compensate for its radius. This feature is essential because cutting tools are not perfectly sharp, and their radius can vary slightly depending on their wear and tear. As a result, the machine needs to account for the tool’s radius to ensure that the cuts are precise and consistent throughout the production process.

Cutter Radius Compensation, or CRC, is a feature in Computer Numerical Control (CNC) machines used to adjust the tool’s path to account for the tool’s radius, ensuring precise cuts. This feature is particularly necessary when the tool’s path and the desired cut have different radii. CNC machines use CRC to create accurate cuts and avoid errors that can result in poor quality or damaged parts.

What is Cutter Radius Compensation in CNC?

Cutter radius compensation (CRC) is a feature of CNC (computer numerical control) machines that allows the machine to adjust the tool’s position to account for the tool’s radius. The CNC machine uses CRC to maintain the desired cutting diameter while the tool moves along a curved path. Without CRC, the tool would cut a path that is too small, resulting in a part that is either too small or has an inconsistent diameter.

How does Cutter Radius Compensation work?

CRC works by adjusting the tool path based on the cutter radius offset value. The offset value is a distance that is added or subtracted from the programmed tool path to account for the tool’s radius. The tool path is generated by the CNC program, which contains information about the part geometry and the tool’s path. The CNC machine reads the program and adjusts the tool path by the offset value to maintain the desired cutting diameter.

The offset value is usually set in the CNC program using a G-code command, such as G41 or G42. The G-code command specifies the direction of the offset (left or right) and the offset amount. The offset value is based on the tool’s radius and the desired cutting diameter.

Types of Cutter Radius Compensation

There are two types of CRC: cutter radius compensation left (G41) and cutter radius compensation right (G42). Cutter radius compensation left is used when the tool is moving to the left of the programmed tool path, and cutter radius compensation right is used when the tool is moving to the right of the programmed tool path.

In addition to G41 and G42, there are also other G-codes used for CRC, such as G40 (cancel cutter radius compensation), G43 (dynamic tool length offset), and G49 (cancel tool length offset).

Benefits of Cutter Radius Compensation

The main benefit of CRC is that it allows for accurate cutting of curved parts with consistent diameter. Without CRC, the tool would cut a path that is too small, resulting in a part that is either too small or has an inconsistent diameter. With CRC, the tool path is adjusted to account for the tool’s radius, resulting in a part with the desired diameter.

Another benefit of CRC is that it reduces tool wear and tool breakage. When the tool path is adjusted for the tool’s radius, the tool is less likely to collide with the part or the machine, which can cause tool breakage or wear.

Cutter Radius Compensation vs. Tool Radius Compensation

Cutter radius compensation is often confused with tool radius compensation (TRC), but they are two different features. TRC adjusts the tool path based on the tool’s radius, while CRC adjusts the tool path based on the cutter radius offset value. TRC is used to compensate for tool wear or to use a different tool with a different radius, while CRC is used to maintain the desired cutting diameter.

Limitations of Cutter Radius Compensation

One limitation of CRC is that it can only compensate for the tool’s radius, not for other factors that can affect the cutting diameter, such as tool deflection or machine accuracy. To compensate for these factors, other features, such as tool center point control (TCPC) or dynamic tool offset (DTO), may be used.

Another limitation of CRC is that it can only compensate for the tool’s radius in one direction at a time. If the tool is moving in both left and right directions, the CRC value must be changed manually to compensate for the direction change.

Cutter Radius Compensation in CAM Software

CAM (computer-aided manufacturing) software is used to generate CNC programs for cutting parts. Most CAM software includes features for CRC, such as automatic detection of the tool radius and automatic generation of the CRC G-code commands. CAM software also allows for easy editing of the CRC values and previewing of the tool path with CRC applied.

Cutter Radius Compensation in Turning and Milling

CRC is used in both turning and milling operations. In turning, CRC is used to maintain the desired cutting diameter when the tool is moving along a curved path. In milling, CRC is used to maintain the desired cutting diameter when the tool is moving along the contour of a part.

In milling, CRC is also used to compensate for the tool’s radius when using a ball nose end mill. Ball nose end mills have a rounded tip, which can result in a larger cutting diameter than the tool’s radius. CRC is used to adjust the tool path to maintain the desired cutting diameter.

Cutter Radius Compensation in 5-Axis Machining

CRC is also used in 5-axis machining, where the tool can move in multiple directions at once. In 5-axis machining, CRC is used to maintain the desired cutting diameter when the tool is moving along a curved path in multiple directions.

In 5-axis machining, CRC is also used to compensate for the tool’s radius when using a ball nose end mill or a tapered tool. CRC is used to adjust the tool path to maintain the desired cutting diameter.

Cutter Radius Compensation in CNC Programming

CNC programming for CRC involves setting the offset value for the tool’s radius and using the appropriate G-code commands for CRC. The offset value is based on the tool’s radius and the desired cutting diameter.

CNC programmers must also consider the direction of the tool path and adjust the CRC value accordingly. They must also consider the type of tool being used and whether TRC or other features are needed to compensate for other factors that can affect the cutting diameter.

Cutter Radius Compensation and Part Accuracy

CRC is essential for maintaining part accuracy in CNC machining. Without CRC, the tool would cut a path that is too small, resulting in a part that is either too small or has an inconsistent diameter. With CRC, the tool path is adjusted to account for the tool’s radius, resulting in a part with the desired diameter.

Part accuracy is critical in many industries, such as aerospace, automotive, and medical, where parts must meet tight tolerances and specifications. CRC is one of the features that allows CNC machines to achieve the required level of accuracy.

Cutter Radius Compensation and CNC Machine Productivity

CRC can also improve CNC machine productivity by reducing tool wear and tool breakage. When the tool path is adjusted for the tool’s radius, the tool is less likely to collide with the part or the machine, which can cause tool breakage or wear. This reduces downtime for tool replacement or repair and increases machine productivity.

In addition, CRC can also reduce the time required to machine a part by allowing for more efficient cutting paths. By maintaining the desired cutting diameter, CRC allows for faster and more efficient cutting while maintaining part accuracy.

Frequently Asked Questions

Here are some commonly asked questions regarding Cutter Radius Compensation in CNC.

What is Cutter Radius Compensation in CNC?

Cutter Radius Compensation is a feature in CNC machining that helps to adjust the tool path based on the size of the cutting tool. It is used to ensure that the tool path matches the intended design, even when the tool has a different radius than the design.

When a CNC machine is programmed to cut a certain shape, it assumes that the cutting tool has a perfectly sharp point. However, in reality, cutting tools have a rounded tip that can affect the accuracy of the cut. Cutter Radius Compensation adjusts the tool path to account for this, ensuring that the cut is made in the correct location.

How does Cutter Radius Compensation work?

Cutter Radius Compensation works by adjusting the coordinates of the tool path based on the radius of the cutting tool. The machine takes the programmed coordinates and calculates the new coordinates based on the size of the tool.

For example, if the machine is programmed to cut a circle with a radius of 1 inch using a tool with a radius of 0.25 inches, the machine will adjust the tool path so that the cut is made at a radius of 1.25 inches. This ensures that the circle is cut accurately, even though the tool has a different radius than the design.

Why is Cutter Radius Compensation important in CNC machining?

Cutter Radius Compensation is important in CNC machining because it ensures that the cut is made accurately and precisely. Without Cutter Radius Compensation, the tool path would not match the intended design, resulting in inaccurate cuts and wasted material.

Additionally, Cutter Radius Compensation can help to extend the life of the cutting tool by reducing the amount of wear and tear on the tool. By adjusting the tool path to account for the tool radius, the machine can reduce the amount of force required to make the cut, which can help to prevent damage to the tool.

What are the different types of Cutter Radius Compensation?

There are two main types of Cutter Radius Compensation: Cutter Compensation Left (G41) and Cutter Compensation Right (G42).

Cutter Compensation Left is used when the cutting tool is on the left side of the programmed path, while Cutter Compensation Right is used when the tool is on the right side of the path. Both types of compensation adjust the tool path based on the radius of the cutting tool, but they do so in different directions.

How do I program Cutter Radius Compensation in my CNC machine?

To program Cutter Radius Compensation in your CNC machine, you will need to use the appropriate G-code command (G41 or G42) in your program.

You will also need to specify the radius of the cutting tool in your program, either by using a tool table or by manually entering the radius. Once you have programmed the tool radius and the appropriate compensation command, the machine will automatically adjust the tool path based on the size of the tool.

In conclusion, Cutter Radius Compensation is a critical feature in CNC machining. It is an essential tool that allows operators to achieve precise cuts and ensure the accuracy of the final product. With Cutter Radius Compensation, the CNC machine can automatically adjust its cutting path to account for the tool’s radius, ensuring that the desired shape and dimensions are achieved.

Without Cutter Radius Compensation, CNC machining would be significantly more challenging and time-consuming. It would require manual calculations and adjustments to achieve the desired results, which would lead to increased production time and potential errors.

Overall, Cutter Radius Compensation is a valuable tool that improves the efficiency and accuracy of CNC machining. Its importance cannot be overstated, and it is an essential feature that every CNC operator should be familiar with to achieve optimal results. By utilizing Cutter Radius Compensation, operators can increase their productivity, reduce waste, and ensure the quality of their products.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com