Table of Contents

Die casting is a widely used manufacturing process that involves the creation of high-quality metal parts with intricate shapes and designs. It is a process where molten metal is injected into a mold under high pressure, producing a final product that is both strong and durable.

Die casting has become an essential part of many industries, including automotive, aerospace, and electronics. With its ability to produce parts quickly and cost-effectively, die casting has revolutionized the manufacturing industry and has become a popular choice for creating complex metal components. In this article, we will explore what die casting is, how it works, and its advantages and disadvantages.

Understanding Die Casting: An Overview

Die casting is a manufacturing process that involves the production of metal parts by forcing molten metal into a reusable steel mold. The metal is then cooled and removed from the mold, resulting in a solid, precise, and accurate part that can be used for different applications. Die casting is widely used in various industries, including automotive, aerospace, medical, and electronics, among others.

How Does Die Casting Work?

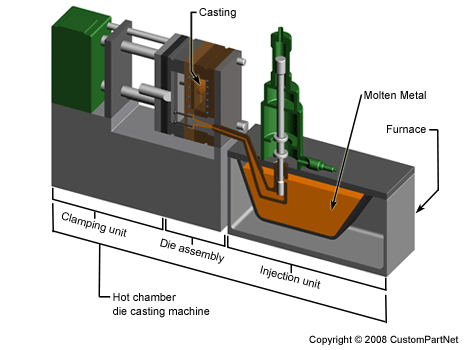

Die casting involves several steps that must be followed strictly to ensure accuracy and precision. The process starts with the preparation of the mold, which is made of high-grade steel and designed to produce the required part. The mold is then coated with a lubricant to prevent the molten metal from sticking to its surface.

The next step involves melting the metal, typically aluminum, zinc, or magnesium, in a furnace. Once the metal is melted, it is injected into the mold at a high pressure using a hydraulic press. The pressure applied ensures that the molten metal fills the entire mold cavity and forms the required part’s shape.

Once the metal has solidified, the mold opens, and the part is ejected. The part is then trimmed, cleaned, and finished to remove any excess material or imperfections, resulting in a high-quality, precise part that meets the required specifications.

Advantages of Die Casting

Die casting offers several advantages over other manufacturing processes, including:

- Precision and accuracy: Die casting produces parts with tight tolerances and high accuracy, making it ideal for applications that require precise parts.

- Cost-effective: Die casting is a cost-effective process, particularly for large production runs, as it requires minimal secondary operations and produces minimal waste.

- High-speed production: Die casting is a high-speed production process, making it ideal for large-scale manufacturing applications.

- Excellent surface finish: Die casting produces parts with a smooth surface finish, eliminating the need for additional finishing operations.

Die Casting vs. Other Manufacturing Processes

Die casting is not the only manufacturing process available, and it is essential to compare it to other processes to determine the best fit. Here are some comparisons between die casting and other manufacturing processes:

| Process | Advantages | Disadvantages |

|---|---|---|

| Injection Molding | High accuracy, low cost, and high-speed production | Limited to small parts, may require additional finishing operations |

| Stamping | High accuracy, low cost, and high-speed production | Limited to flat parts, may require additional finishing operations |

| Machining | High accuracy, suitable for a wide range of materials and part sizes | Higher cost, longer production time, and generates more waste |

Conclusion

Die casting is a versatile and reliable manufacturing process that produces high-quality, precise, and accurate parts. It is widely used in various industries and offers several advantages over other manufacturing processes, including cost-effectiveness, high-speed production, and excellent surface finish. By understanding the process and comparing it to other processes, you can determine if die casting is the best fit for your manufacturing needs.

Frequently Asked Questions

In the manufacturing industry, die casting is a widely used process for producing metal parts with high precision and accurate detailing. This process involves the use of metal alloys that are melted and then injected into a mold to create the desired shapes and forms. If you want to learn more about die casting, here are some commonly asked questions and their answers.

What is die casting?

Die casting is a manufacturing process that involves injecting molten metal alloys into a die or mold cavity. The molten metal is forced into the mold with high pressure, which allows it to take on the shape of the mold. This process is used to produce complex parts with high accuracy and precision, and it is commonly used in the automotive, aerospace, and electronics industries.

The die casting process can be performed using a range of materials, including aluminum, zinc, magnesium, and copper. The choice of material depends on the specific requirements of the part, such as strength, weight, and durability.

What are the advantages of die casting?

Die casting offers several advantages over other manufacturing processes. Firstly, it allows for the production of complex parts with high accuracy and precision. Secondly, it is a cost-effective process, as it can produce large quantities of parts quickly and efficiently. Thirdly, die casting produces parts that are strong, durable, and lightweight, making them ideal for use in the automotive and aerospace industries.

Another advantage of die casting is that it can produce parts with a smooth surface finish, which eliminates the need for additional finishing processes. This can save time and money in the production process, making die casting a popular choice for manufacturers around the world.

What types of products can be produced using die casting?

Die casting can be used to produce a wide range of products, including automobile parts, electronic components, and household appliances. The process is particularly well-suited to the production of complex parts with high precision and accuracy, such as engine blocks, transmission components, and gearboxes.

Die casting is also commonly used to produce parts that need to be lightweight and strong, such as those used in the aerospace industry. The process can produce parts with thin walls and intricate shapes, which can be difficult to achieve using other manufacturing processes.

What are the limitations of die casting?

While die casting offers many advantages, it also has some limitations. Firstly, it is not suitable for producing very large parts, as the size of the die or mold cavity is limited. Secondly, die casting is not suitable for producing parts with very thin walls, as the metal may not flow evenly into the mold.

Another limitation of die casting is that it can be expensive to set up the equipment required for the process. This can make it a less viable option for smaller production runs or for producing parts that are only needed in small quantities.

How does die casting compare to other manufacturing processes?

Die casting is just one of many manufacturing processes used in industry today. Other processes include forging, stamping, and machining. Each process has its own advantages and disadvantages, and the choice of process depends on the specific requirements of the part being produced.

Die casting is often preferred over other processes for its ability to produce complex parts with high accuracy and precision, as well as its cost-effectiveness for large production runs. However, each process has its own set of limitations, and manufacturers must carefully consider their options when choosing a production method.

In conclusion, die casting is a manufacturing process that has revolutionized the production of various metal components. The process relies on the use of high-pressure injection to create intricate parts with high precision and accuracy. As a result, die casting has become increasingly popular in the production of automotive, aerospace, and consumer goods.

Die casting is a versatile process that can be used to produce a wide range of components with varying degrees of complexity. The process is highly efficient and can produce high-quality parts at a low cost. This makes it an attractive option for manufacturers looking to improve their production processes and reduce costs.

Overall, die casting is an important manufacturing process that has transformed the way we produce metal components. With its ability to produce complex parts with high precision and efficiency, die casting remains a popular choice for manufacturers in a wide range of industries.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com