Table of Contents

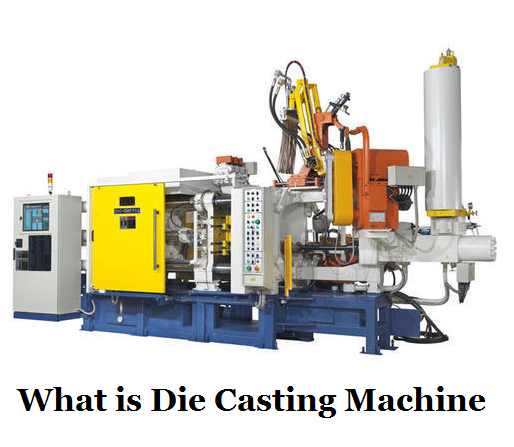

Die casting is a popular manufacturing process that is widely used to produce complex metal parts with excellent accuracy and surface finish. It involves injecting molten metal into a mold cavity under high pressure to create intricate shapes and designs. A die casting machine is a crucial tool that makes this process possible, and it plays a crucial role in the production of various products, from automotive parts to consumer electronics.

Die casting machines come in different sizes and types, ranging from small desktop machines to large industrial machines that can produce thousands of parts per hour. They use a variety of techniques and technologies to ensure high-quality casting results, including computer-aided design, automated process control, and advanced cooling systems. In this article, we will take a closer look at what a die casting machine is, how it works, and its various applications across different industries.

Die Casting Machine: A die casting machine is a manufacturing tool that is used to produce metal parts by injecting molten metal into a die (mold) under high pressure. The machine consists of two main parts: the injection unit and the clamping unit. The injection unit melts and injects the molten metal into the die, while the clamping unit holds the die closed and applies the necessary pressure to produce the part. Die casting machines are commonly used to produce parts for the automotive, aerospace, and electronics industries.

Understanding Die Casting Machines

Die casting is a manufacturing process that is used to produce metal parts of various shapes and sizes. It involves injecting molten metal into a mold or die to create a solid part. Die casting machines are used in this process to apply high pressure and temperature to the metal, ensuring that it fills the mold cavity completely. In this article, we will take a closer look at what die casting machines are and how they work.

What are Die Casting Machines?

Die casting machines are specialized equipment used in the die casting process. They are designed to apply high pressure to molten metal, which is then injected into a mold or die. The machines consist of two main parts: the injection unit and the clamping unit.

The injection unit is responsible for melting the metal and injecting it into the die. It consists of a furnace, a plunger, and a gooseneck. The furnace melts the metal, which is then injected into the gooseneck. The plunger then forces the molten metal through the gooseneck and into the die.

The clamping unit, on the other hand, is responsible for holding the die in place and applying the necessary pressure to the metal. It consists of a mold or die, a shot sleeve, and a hydraulic system. The mold or die is designed to create the desired shape of the part, while the shot sleeve helps to regulate the flow of metal into the mold. The hydraulic system provides the required pressure to fill the mold completely.

Types of Die Casting Machines

There are two main types of die casting machines: hot chamber machines and cold chamber machines. Hot chamber machines are used for metals with low melting points, such as zinc, tin, and lead. They have a built-in furnace that melts the metal, making the process more efficient.

Cold chamber machines, on the other hand, are used for metals with high melting points, such as aluminum, copper, and magnesium. They do not have a built-in furnace, so the metal must be melted separately before being injected into the machine.

Components of Die Casting Machines

Die casting machines consist of several components, including the furnace, plunger, gooseneck, mold, shot sleeve, and hydraulic system. Each component plays a vital role in the die casting process.

The furnace is used to melt the metal, while the plunger and gooseneck inject the molten metal into the mold. The mold is designed to create the desired shape of the part, and the shot sleeve helps to regulate the flow of metal into the mold. The hydraulic system provides the necessary pressure to fill the mold completely.

Benefits of Die Casting Machines

Die casting machines offer several benefits over other manufacturing processes. They are capable of producing parts with high precision and accuracy, making them ideal for industries that require tight tolerances. They also have a high production rate, making them suitable for mass production.

Die casting machines are also versatile and can be used to produce parts of various shapes and sizes. They can produce parts with complex geometries and intricate designs, making them ideal for industries such as automotive, aerospace, and electronics.

Die Casting Machines vs Other Manufacturing Processes

Die casting machines offer several advantages over other manufacturing processes, such as sand casting and investment casting. They have a higher production rate and can produce parts with higher precision and accuracy. They are also more cost-effective, as they require less labor and material.

However, die casting machines are not suitable for all types of metals. They are only suitable for metals with low to medium melting points, making them unsuitable for metals with high melting points, such as steel.

Conclusion

Die casting machines are specialized equipment used in the die casting process. They are designed to apply high pressure and temperature to molten metal, ensuring that it fills the mold cavity completely. Die casting machines are used in various industries to produce parts with high precision and accuracy. They offer several benefits over other manufacturing processes, such as sand casting and investment casting. However, they are not suitable for all types of metals and are only suitable for metals with low to medium melting points.

Frequently Asked Questions

What is a Die Casting Machine?

A die casting machine is a piece of machinery used in the manufacturing process of metal parts. It is used to create precision parts with a high level of accuracy and consistency. The machine works by injecting molten metal into a mold or die, which is then cooled and hardened to create a solid metal part. Die casting machines are commonly used in the automotive, aerospace, and electronics industries.

Die casting machines come in a variety of sizes and configurations, depending on the specific needs of the manufacturing process. They can be operated manually or automatically, and can be used to produce a wide range of metal parts. Some of the most common materials used in die casting include aluminum, zinc, and magnesium.

What are the Benefits of Using a Die Casting Machine?

There are several benefits to using a die casting machine for metal part manufacturing. One of the biggest advantages is the high level of accuracy and consistency that can be achieved with this process. Die casting machines are able to produce parts with very tight tolerances, which is essential in many industries.

Another benefit of using a die casting machine is the speed and efficiency of the process. These machines are able to produce large quantities of parts in a relatively short amount of time, which can help to keep production costs low.

Finally, die casting machines are also very versatile, and can be used to produce a wide range of parts in different shapes and sizes. This makes them ideal for a variety of applications, from small electronic components to large automotive parts.

What are the Different Types of Die Casting Machines?

There are several different types of die casting machines available, each with its own unique features and benefits. One of the most common types is the cold chamber die casting machine, which is used for casting metals with high melting points such as aluminum and copper.

Another type of die casting machine is the hot chamber die casting machine, which is used for casting metals with lower melting points such as zinc and magnesium. This type of machine is smaller and more compact than the cold chamber machine, and is often used for producing smaller parts.

Finally, there are also multi-slide die casting machines, which are used for producing complex parts with multiple angles and curves. These machines are typically more expensive than other types, but offer greater flexibility and precision.

What Factors Should be Considered When Choosing a Die Casting Machine?

When choosing a die casting machine, there are several factors to consider. One of the most important is the type of metal being used, as different metals require different types of machines and processes.

Other factors to consider include the size and complexity of the parts being produced, as well as the required production volume. The cost of the machine is also an important consideration, as well as the level of automation and control offered by the machine.

Ultimately, the best die casting machine will depend on the specific needs of the manufacturing process, as well as the budget and resources available.

What are the Safety Considerations When Operating a Die Casting Machine?

There are several safety considerations that should be taken into account when operating a die casting machine. First and foremost, it is important to ensure that all operators are properly trained in the safe operation of the machine, and that they understand the risks and hazards associated with the process.

Other safety considerations include ensuring that the machine is properly maintained and inspected on a regular basis, and that all safety guards and protective equipment are in place and functioning properly.

It is also important to follow all recommended safety procedures, such as wearing appropriate personal protective equipment, and ensuring that the work area is clear of any potential hazards. By taking these safety considerations into account, it is possible to minimize the risk of accidents and injuries when operating a die casting machine.

In conclusion, die casting machines are an essential tool for creating complex metal parts with high precision and efficiency. These machines use high pressure to inject molten metal into custom molds, resulting in a finished product that is durable and consistent in quality.

Die casting machines have come a long way since their inception, with modern machines featuring advanced controls, automated processes, and eco-friendly features. The ability to produce large quantities of parts quickly and cost-effectively has made die casting a popular choice in various industries, from automotive to aerospace.

Despite the many advantages of die casting, it is essential to choose the right machine for your specific needs. Factors such as the type of metal being used, the complexity of the part, and the required production volume should all be considered when selecting a die casting machine. By selecting the right machine and following proper maintenance procedures, businesses can enjoy the many benefits of die casting for years to come.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com