Table of Contents

Are you interested in CNC machining? If yes, then you might have heard of Grbl CNC. Grbl CNC is a popular open-source software used in CNC machines for controlling and managing their movements. It has gained popularity due to its simplicity, affordability, and ease of use.

Grbl CNC is perfect for hobbyists and DIY enthusiasts who want to build their own CNC machines. It is compatible with various hardware platforms and can be easily customized to fit different projects. In this article, we will explore the basics of Grbl CNC and its key features, helping you understand why it is such a popular choice in the CNC community.

H2: What is Grbl CNC?

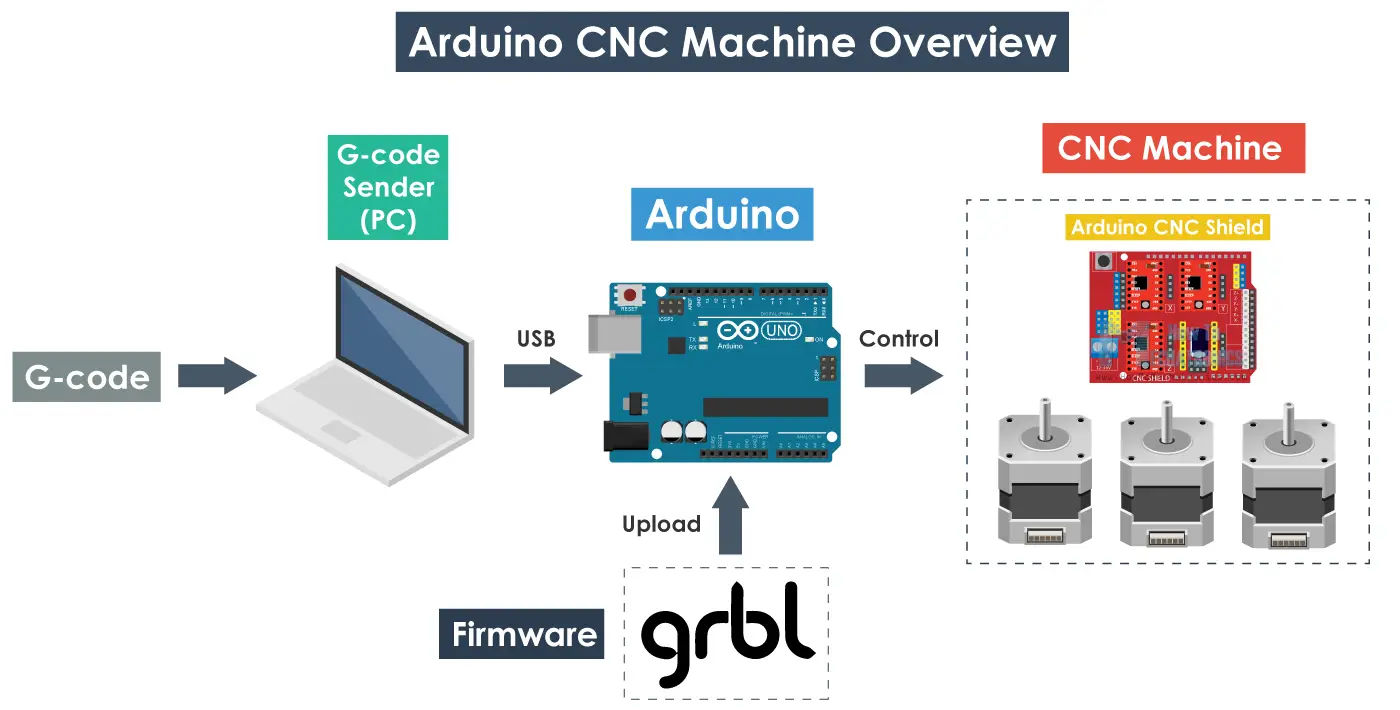

Grbl CNC is a firmware for controlling CNC machines, which stands for Computer Numerical Control. It is a programming language that controls the movement of the machine’s axes, allowing for precision cutting, drilling, and carving. Grbl CNC is designed to be used with Arduino-based microcontrollers, allowing for an affordable and accessible way for hobbyists and professionals alike to create intricate designs with ease.

H3: How does Grbl CNC work?

Grbl CNC uses a combination of G-code commands and motion control algorithms to translate digital designs into physical creations. G-code is a computer language that is used to program CNC machines, and it contains instructions for the machine’s movements, such as the speed and direction of the cutting tool. Grbl CNC interprets these commands and uses its motion control algorithms to move the machine’s axes in the specified directions.

Grbl CNC is designed to work with a wide range of CNC machines, including routers, mills, and laser cutters. It is compatible with a variety of different operating systems, including Windows, Mac, and Linux, making it accessible to users with different preferences.

H3: What are the benefits of using Grbl CNC?

There are many benefits to using Grbl CNC for your CNC projects. Firstly, it is open-source software, which means that it is free to use and modify, and there is a large community of developers working to improve the software and add new features. This also means that there are many resources available online, such as forums and tutorials, which can help you learn how to use the software effectively.

Another benefit of Grbl CNC is its ease of use. The software is designed to be user-friendly, with a simple interface that allows you to input your G-code commands and start your project quickly. Additionally, Grbl CNC is designed to be compatible with a wide range of CNC machines, making it a versatile tool for hobbyists and professionals alike.

H3: Grbl CNC Vs. Other CNC software

One of the main advantages of using Grbl CNC over other CNC software is its affordability. Because it is open-source software, it is free to use and modify, making it an accessible option for hobbyists and small businesses. Additionally, Grbl CNC is designed to be compatible with a wide range of CNC machines, which means that you can use it with the equipment you already have, rather than having to invest in new machinery.

Another advantage of Grbl CNC is its ease of use. The software is designed to be user-friendly, with a simple interface that allows you to input your G-code commands and start your project quickly. This can be particularly helpful for beginners who are just starting out with CNC machining.

However, it is important to note that Grbl CNC may not be the best option for all users. Depending on your specific needs and the type of CNC machine you are using, other software options may be more suitable. It is important to do your research and compare different software options before making a decision.

H3: How to get started with Grbl CNC

Getting started with Grbl CNC is relatively simple. Firstly, you will need to download the software onto your computer. This can be done from the Grbl website, where you can also find instructions for installing the software.

Once you have installed Grbl CNC, you will need to connect it to your CNC machine. This can be done using an Arduino-based microcontroller, which can be purchased online or from electronics stores. You will also need to connect the machine’s motors and other components to the microcontroller, following the instructions provided by the manufacturer.

Once your machine is set up and connected to Grbl CNC, you can start inputting your G-code commands and running your projects. There are many resources available online to help you learn how to use the software effectively, such as forums and tutorials.

H3: Grbl CNC limitations

While Grbl CNC is a powerful tool for CNC machining, it does have some limitations. One of these limitations is its compatibility with certain types of CNC machines. While it is designed to be compatible with a wide range of machines, some users may find that it is not suitable for their specific needs.

Another limitation of Grbl CNC is its lack of advanced features. While the software is designed to be user-friendly and accessible, it may not have the advanced capabilities that some professionals require. However, there are many other software options available that may be more suitable for these users.

H3: Conclusion

Grbl CNC is a powerful and accessible tool for CNC machining, offering users a wide range of features and benefits. Whether you are a hobbyist or a professional, Grbl CNC can help you create intricate designs with ease, thanks to its user-friendly interface and compatibility with a wide range of CNC machines. While it may not be the best option for all users, it is certainly worth considering for those looking for an affordable and accessible way to get started with CNC machining.

Frequently Asked Questions

What is Grbl CNC?

Grbl CNC is a type of firmware commonly used in CNC machines. It is an open-source, high-performance software that runs on an Arduino board. Grbl CNC is used to control CNC machines, which are machines that use computer programs to control the movement of tools and parts.

Grbl CNC is designed to be easy to use, flexible, and powerful. It is compatible with a wide range of CNC machines and can be easily customized to meet specific needs. Grbl CNC supports a variety of different CNC machines, including mills, routers, and plasma cutters. It is often used by hobbyists, makers, and small businesses.

How does Grbl CNC work?

Grbl CNC works by interpreting G-code, which is a programming language used to control CNC machines. The G-code is sent to the Grbl CNC firmware, which then translates the code into commands that control the movement of the machine.

Grbl CNC is designed to be highly efficient and fast, which means it can handle complex G-code programs with ease. It uses a real-time motion planning algorithm to ensure smooth and precise movement of the machine. Grbl CNC also includes advanced features such as laser and spindle control, homing and limit switches, and real-time overrides.

What are the benefits of using Grbl CNC?

There are many benefits to using Grbl CNC. One of the main benefits is its ease of use. Grbl CNC is designed to be simple and intuitive, which means even beginners can use it to control their CNC machines.

Another benefit of Grbl CNC is its flexibility. It can be customized to meet specific needs and can be used with a wide range of CNC machines. Grbl CNC also includes advanced features such as real-time overrides and homing and limit switches, which can help improve the accuracy and precision of your CNC machine.

Can Grbl CNC be used with any CNC machine?

Grbl CNC is compatible with a wide range of CNC machines, including mills, routers, and plasma cutters. However, not all CNC machines are compatible with Grbl CNC. It is important to check the specifications of your machine to ensure compatibility.

If your machine is not compatible with Grbl CNC, there are other firmware options available that may be suitable. It is always best to consult the manufacturer or a qualified technician before installing any new firmware on your CNC machine.

How do I install and use Grbl CNC?

Installing and using Grbl CNC is relatively simple. First, you will need to download the Grbl CNC firmware and install it on your Arduino board. Once the firmware is installed, you can connect your CNC machine to your computer using a USB cable.

To use Grbl CNC, you will need to create or download a G-code program and send it to the firmware using a G-code sender program. There are many free G-code senders available online, such as Universal Gcode Sender and Chilipeppr. Once you have sent the G-code program to the firmware, Grbl CNC will interpret the code and control the movement of your CNC machine.

In conclusion, Grbl CNC is a powerful open-source firmware that allows users to control their CNC machines with ease. It is designed to be user-friendly and compatible with a wide range of machines. With its advanced features and easy-to-use interface, it has become a popular choice for hobbyists and professionals alike.

Whether you’re a seasoned CNC user or just starting out, Grbl CNC is a great tool to have in your arsenal. It provides precise and accurate control over your machine, allowing you to create complex designs and intricate cuts with ease.

In short, if you’re looking for a reliable and user-friendly CNC firmware, Grbl CNC is definitely worth considering. With its advanced features and ease of use, it is sure to take your CNC projects to the next level.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com