Table of Contents

High Pressure Die Casting is a manufacturing process that involves injecting molten metal into a highly durable steel mold under extreme pressure. The process is widely used in the automotive, aerospace, and electronics industries to produce complex and precise metal parts.

One of the advantages of High Pressure Die Casting is its ability to produce parts with excellent dimensional accuracy, tight tolerances, and smooth surface finishes. This process also allows for the production of large quantities of parts in a relatively short amount of time, making it an ideal choice for mass production.

What is High Pressure Die Casting?

High pressure die casting (HPDC) is a metal casting process widely used in the manufacturing industry. It involves injecting molten metal under high pressure into a mold cavity. The molten metal is forced into the mold cavity, where it solidifies and takes the shape of the mold. HPDC is a popular choice for mass production of complex metal parts with high dimensional accuracy and surface finish.

Process of High Pressure Die Casting

High pressure die casting involves several steps, including:

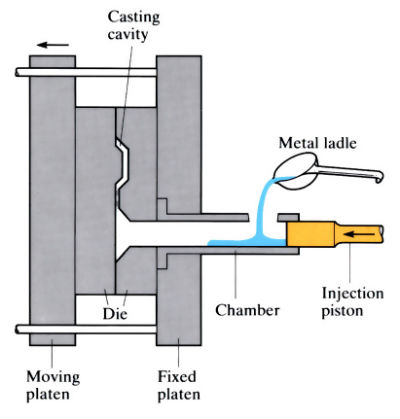

- Melting: The metal is melted in a furnace and transferred to the die casting machine.

- Injection: The molten metal is injected into the mold cavity under high pressure.

- Cooling: The metal solidifies and cools in the mold cavity.

- Ejection: The part is ejected from the mold cavity.

- Trimming: Excess material is removed from the part.

HPDC is a precise and efficient manufacturing process that allows for the production of complex shapes with tight tolerances. The high pressure used in the process ensures that the metal fills the mold cavity completely and uniformly, resulting in parts with a high degree of consistency and accuracy. HPDC is commonly used to produce parts for the automotive, aerospace, and electronics industries, among others.

Advantages of High Pressure Die Casting

HPDC offers several advantages over other casting processes, including:

- High production rates: HPDC is a fast and efficient process, allowing for the production of large quantities of parts in a short amount of time.

- Complex shapes: The high pressure used in the process allows for the production of complex shapes with intricate details and tight tolerances.

- Cost-effective: HPDC is a cost-effective process, as it requires minimal finishing and machining compared to other casting processes.

- Wide range of materials: HPDC can be used with a wide range of metals and alloys, including aluminum, zinc, and magnesium.

Disadvantages of High Pressure Die Casting

Despite its many advantages, HPDC also has some disadvantages, including:

- Initial costs: HPDC requires expensive equipment and tooling, making it less suitable for small-scale production runs.

- Design limitations: HPDC requires specific design considerations to ensure that the metal can flow into the mold cavity properly.

- Porosity: HPDC can result in porosity in the finished parts, which can affect their strength and durability.

- Surface defects: HPDC can result in surface defects such as air pockets and shrinkage, which can affect the appearance of the finished parts.

High Pressure Die Casting vs. Other Casting Processes

There are several casting processes available, each with its own advantages and disadvantages. Here’s how HPDC compares to other casting processes:

| Advantages | Disadvantages | |

|---|---|---|

| High Pressure Die Casting | Fast and efficient Complex shapes Cost-effective Wide range of materials |

Expensive equipment and tooling Design limitations Porosity Surface defects |

| Gravity Casting | Low tooling costs Less porosity Greater design flexibility |

Slower production rates Less precise Less suitable for complex shapes |

| Sand Casting | Low tooling costs Can produce large parts Wide range of materials |

Slow production rates Less precise Requires finishing and machining |

| Investment Casting | High dimensional accuracy Smooth surface finish Can produce complex shapes |

Expensive tooling costs Slow production rates Less suitable for large parts |

Conclusion

High pressure die casting is a widely used metal casting process that offers several advantages over other casting processes. It is a fast and efficient process that allows for the production of complex shapes with high dimensional accuracy and surface finish. However, it also has some disadvantages, including initial costs and design limitations. Despite these drawbacks, HPDC remains a popular choice for mass production of metal parts in a variety of industries.

Frequently Asked Questions

High pressure die casting is a metal casting process that is widely used in various industries. It involves injecting molten metal into a mold at high pressure and high speed, to produce high-quality parts with excellent surface finish and dimensional accuracy. Here are some frequently asked questions about high pressure die casting.

What materials can be used in high pressure die casting?

High pressure die casting can be used to cast a wide range of metals and alloys, including aluminum, zinc, magnesium, copper, brass, and others. The choice of material depends on the requirements of the application, such as strength, weight, corrosion resistance, and cost. Aluminum is the most commonly used material, as it offers a good balance of properties and is relatively easy to cast.

Before casting, the material is melted in a furnace and is then transported to the die casting machine. The molten metal is then injected into the mold under high pressure, filling all the cavities and producing the desired shape. The mold is then opened, and the casting is ejected from the machine.

What are the advantages of high pressure die casting?

High pressure die casting offers several advantages over other casting methods, such as sand casting and investment casting. It is a high-speed process that can produce large quantities of parts with high dimensional accuracy and excellent surface finish. It also allows for the production of complex shapes with thin walls and intricate details.

In addition, high pressure die casting can produce parts with good mechanical properties, such as high strength, stiffness, and ductility. The process is also highly automated, which reduces labor costs and improves production efficiency. Finally, high pressure die casting can be used to produce parts with a wide range of sizes, from small components to large automotive parts.

What are the limitations of high pressure die casting?

Although high pressure die casting has many advantages, it also has some limitations. One of the main limitations is the size of the part that can be cast. High pressure die casting is best suited for small to medium-sized parts, typically weighing between a few grams and a few kilograms.

Another limitation is the shape of the part. High pressure die casting is best suited for parts with simple to moderately complex shapes, as more complex shapes may require additional machining or assembly operations. Finally, high pressure die casting is not suitable for all materials, as some materials may be difficult to cast or may require specialized equipment.

What are the applications of high pressure die casting?

High pressure die casting is used in a wide range of industries, such as automotive, aerospace, electronics, and consumer goods. It is used to produce a variety of parts, such as engine blocks, transmission cases, wheels, brackets, housings, and others.

The automotive industry is one of the largest users of high pressure die casting, as it allows for the production of lightweight parts with high strength and stiffness. The aerospace industry also uses high pressure die casting to produce parts for aircraft engines and structures. In addition, high pressure die casting is used in the production of consumer goods, such as toys, sporting equipment, and household appliances.

What are the quality control measures in high pressure die casting?

High pressure die casting requires strict quality control measures to ensure that the parts meet the required specifications. The quality control measures include inspection of the raw materials, monitoring of the casting process, and testing of the finished parts.

The raw materials, such as the metal alloy and the lubricants, are inspected for quality and consistency. The casting process is monitored for parameters such as temperature, pressure, and injection speed. The finished parts are tested for dimensional accuracy, surface finish, and mechanical properties, such as strength and ductility.

In conclusion, high pressure die casting is a versatile and efficient manufacturing process that has revolutionized the production of complex metal parts. This process involves the use of high pressure to force molten metal into a mold, resulting in high-quality products with exceptional accuracy and precision.

One of the key advantages of high pressure die casting is its ability to produce parts with thin walls and intricate shapes that would be difficult to achieve using other methods. Additionally, this process has a high level of repeatability, allowing for consistent production of identical parts.

Overall, high pressure die casting is an essential process in modern manufacturing, providing a cost-effective and reliable way to produce high-quality metal parts. Its versatility and precision make it ideal for a wide range of industries, from automotive and aerospace to electronics and consumer goods.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com