Table of Contents

If you’ve ever wondered how plastic products are made, you’ve likely stumbled upon the term “injection molding.” Injection molding is the most popular manufacturing process for plastic products, and it’s used to make everything from car parts to toys.

At its core, injection molding involves melting plastic pellets and injecting them into a mold. But the process is much more complex than that, involving a range of equipment, materials, and techniques. In this article, we’ll explore the ins and outs of injection molding and take a closer look at why it’s such a popular manufacturing method.

What is Injection Molding?

Injection molding is a manufacturing process used to produce complex and intricate parts and products by injecting molten material into a mold cavity. It is one of the most widely used manufacturing processes in the world and is used to produce a variety of products, including automotive parts, toys, medical equipment, and consumer electronics.

The Injection Molding Process

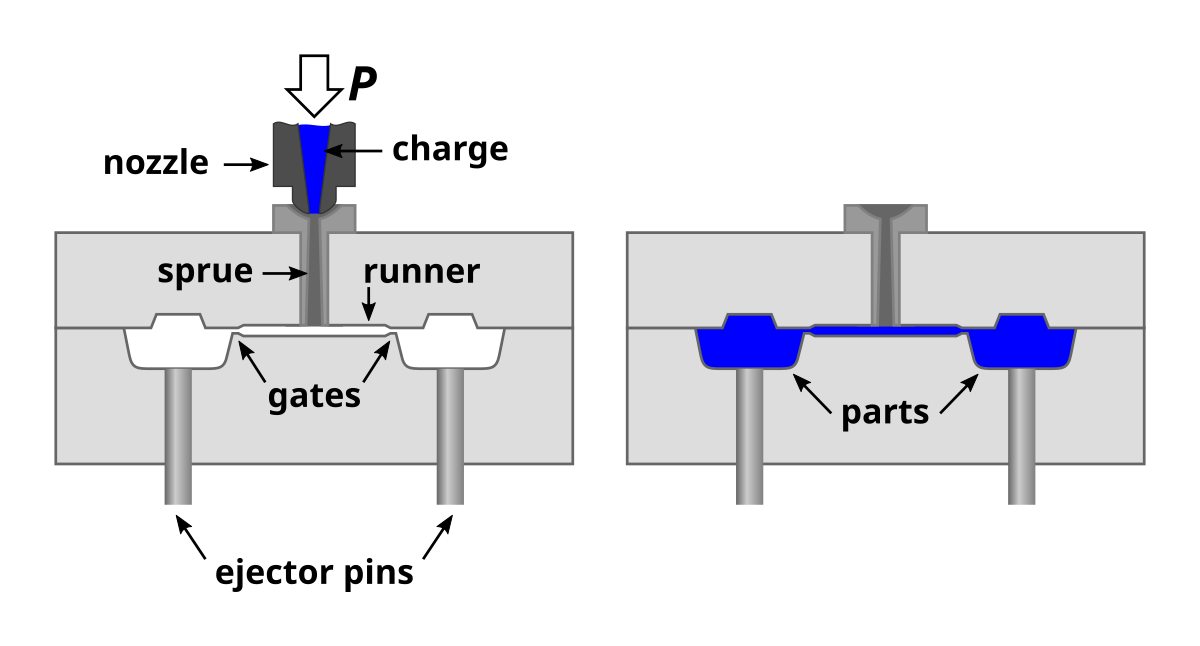

Injection molding is a highly efficient and precise manufacturing process. The process starts with the creation of a mold, which is the negative image of the part to be produced. The mold is then mounted on an injection molding machine, which is equipped with a hopper that feeds the plastic material into a heated barrel.

Once the plastic material is melted, it is injected into the mold cavity at high pressure. The pressure ensures that the material fills the mold completely, and the mold is then cooled to solidify the material. The mold is then opened, and the part is ejected.

The injection molding process can be used to produce parts with complex geometries, and it offers excellent repeatability and precision. It is a highly automated process that can produce high volumes of parts quickly and efficiently.

Materials Used in Injection Molding

Injection molding can be used with a wide variety of materials, including thermoplastics, thermosets, and elastomers. Thermoplastics are the most commonly used materials in injection molding and include materials such as polyethylene, polypropylene, and polycarbonate.

Thermosets, such as epoxy and phenolic resins, are used in applications that require high temperature resistance, while elastomers, such as rubber, are used in applications that require flexibility and resilience.

Benefits of Injection Molding

Injection molding offers a number of benefits over other manufacturing processes. It allows for the production of complex and intricate parts with high precision and repeatability. It is a highly automated process that can produce high volumes of parts quickly and efficiently.

Injection molding also offers design flexibility, allowing for the creation of parts with complex geometries and features. It is a cost-effective process for high volume production runs, and it can reduce the need for secondary operations, such as machining and finishing.

Injection Molding vs Other Manufacturing Processes

Injection molding offers several advantages over other manufacturing processes. For example, it can produce parts with complex geometries that would be difficult or impossible to produce with other processes, such as machining or casting.

Injection molding is also more cost-effective than other processes for high volume production runs. It can also reduce the need for secondary operations, such as machining and finishing, which can further reduce costs.

Common Applications of Injection Molding

Injection molding is used to produce a wide variety of products, including automotive parts, toys, medical equipment, and consumer electronics. It is also used in the production of household items, such as kitchen utensils and containers.

The versatility of injection molding makes it a popular choice for manufacturers across a range of industries. It is a highly efficient and cost-effective process that can produce high volumes of parts quickly and efficiently.

Quality Control in Injection Molding

Quality control is an important aspect of injection molding. Manufacturers must ensure that the parts they produce meet the required specifications and standards. This involves monitoring the process parameters, such as temperature, pressure, and cycle time, to ensure that the parts are produced consistently and accurately.

Quality control also involves inspecting the parts for defects, such as warping, sink marks, and flash. Manufacturers may use a variety of techniques, such as visual inspection, dimensional measurement, and material testing, to ensure that the parts meet the required quality standards.

Environmental Considerations in Injection Molding

Injection molding can have environmental impacts, primarily due to the use of plastic materials. Manufacturers must ensure that they use materials that are environmentally responsible and that they dispose of waste materials properly.

There are also opportunities for manufacturers to reduce the environmental impact of injection molding by using recycled materials and optimizing the manufacturing process to reduce energy consumption and waste.

Conclusion

Injection molding is a highly efficient and precise manufacturing process that is used to produce a wide variety of parts and products. It offers many benefits over other manufacturing processes, including the ability to produce complex geometries with high precision and repeatability.

Manufacturers must ensure that they use environmentally responsible materials and that they dispose of waste materials properly. Quality control is also an important aspect of injection molding, and manufacturers must ensure that the parts they produce meet the required specifications and standards.

Frequently Asked Questions

What is Injection Molding?

Injection molding is a manufacturing process that involves injecting molten material into a mold cavity under high pressure. The molten material then cools and solidifies, forming a final product. Injection molding is commonly used to produce plastic parts, but it can also be used for metal, glass, and other materials.

The injection molding process begins with the creation of a mold, which is usually made of steel or aluminum. The mold is designed to the exact specifications of the final product and is then mounted onto an injection molding machine. The machine heats the material to its melting point and then injects it into the mold. Once the material has cooled and solidified, the mold is opened and the finished product is removed.

What are the advantages of Injection Molding?

Injection molding offers several advantages over other manufacturing processes. First, it can produce complex shapes and intricate details that would be difficult or impossible to achieve with other methods. Second, it is a highly efficient process that can produce large quantities of parts quickly and consistently. Finally, it is a cost-effective method for producing high-quality parts in large volumes.

One of the key advantages of injection molding is its versatility. It can be used to produce a wide range of products in different shapes, sizes, and materials. From small, intricate parts to large, durable components, injection molding can be used to create virtually any type of product.

What types of materials can be used in Injection Molding?

Injection molding can be used with a wide range of materials, including plastics, metals, and glass. Some of the most commonly used materials for injection molding include polypropylene, polystyrene, nylon, and ABS. Each material has its own unique properties and benefits, and the choice of material will depend on the specific requirements of the final product.

When selecting a material for injection molding, it is important to consider factors such as strength, durability, flexibility, and heat resistance. Different materials will also have different melting points, which can affect the molding process and the quality of the final product.

What are the limitations of Injection Molding?

While injection molding offers many advantages, there are also some limitations to the process. One of the main limitations is the high cost of creating the initial mold. This can be a significant investment, especially for small businesses or those producing a limited number of parts.

Another limitation is the size and complexity of the parts that can be produced. While injection molding can create complex shapes and intricate details, there are limits to the size and thickness of the parts that can be produced. Additionally, some materials may not be suitable for injection molding due to their properties or cost.

What is the process for designing a part for Injection Molding?

Designing a part for injection molding requires careful consideration of several factors. The first step is to create a 3D model of the part using CAD software. This model is then used to create a mold design that will be used in the injection molding process.

During the design process, it is important to consider factors such as the material being used, the size and shape of the part, and any special features or requirements. The mold design will also need to include details such as the location of gates and vents, which control the flow of material into the mold cavity. Once the design is complete, a prototype can be created to test the part and make any necessary adjustments before beginning the production process.

To sum up, injection molding is a widely used manufacturing process that allows for the mass production of complex plastic parts. It involves the use of a mold, which is filled with molten plastic material that is then cooled and solidified into the desired shape. This process is highly efficient and produces high-quality, precise parts that can be used in a variety of industries.

Furthermore, injection molding allows for great design flexibility and can produce parts with intricate shapes and features that would be difficult or impossible to achieve with other manufacturing methods. It is also a cost-effective solution for producing large quantities of parts, as the initial setup costs are offset by the ability to produce parts quickly and consistently.

In conclusion, injection molding is an essential process for modern manufacturing, allowing for the creation of a wide range of high-quality plastic parts with great efficiency and design flexibility. Its importance in various industries cannot be overstated, and it will continue to be an integral part of manufacturing for years to come.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com