Table of Contents

Laser Additive Manufacturing (LAM) is a cutting-edge technology that has revolutionized the manufacturing industry. LAM is a process where a laser beam is used to melt and fuse materials together, layer by layer, to create a 3D object.

This technology has gained popularity due to its ability to create complex shapes and designs that were previously impossible to manufacture. In this article, we will explore the basics of LAM and its applications in various industries. So let’s dive in and discover the world of Laser Additive Manufacturing!

What is Laser Additive Manufacturing?

Laser additive manufacturing is a process that uses laser beams to create three-dimensional objects by adding material layer by layer. It is a rapid manufacturing process that has gained popularity in recent years due to its ability to produce complex geometries and functional parts with high precision. In this article, we will explore the basics of laser additive manufacturing and how it works.

How does Laser Additive Manufacturing work?

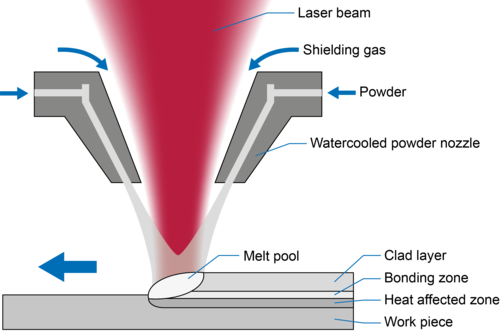

Laser additive manufacturing involves the use of a high-powered laser beam to melt and fuse powdered or wire-based materials, layer by layer, to create a three-dimensional object. The process involves the use of a computer-aided design (CAD) file that is used to guide the laser beam to create the desired shape.

The process begins with the deposition of the first layer of material onto a build platform. The laser beam is then directed onto the material, melting it and fusing it together. This process is repeated layer by layer until the final product is complete.

The Benefits of Laser Additive Manufacturing

Laser additive manufacturing has several benefits over traditional manufacturing methods. One of the primary benefits is the ability to create complex geometries that would be difficult or impossible to produce using traditional methods. This makes laser additive manufacturing ideal for creating prototypes and small production runs.

Another benefit is the ability to produce parts with high precision and accuracy. The use of computer-aided design (CAD) files ensures that parts are produced to exact specifications, reducing the need for post-processing and improving quality control.

Laser Additive Manufacturing Vs. Traditional Manufacturing Methods

Laser additive manufacturing has several advantages over traditional manufacturing methods such as casting, forging, and machining. One of the primary advantages is the ability to produce complex geometries with high precision and accuracy. Traditional manufacturing methods are limited by the tools and processes used, making it difficult to produce parts with intricate shapes.

Another advantage of laser additive manufacturing is the ability to reduce waste. Traditional manufacturing methods often result in significant material waste due to the need to remove excess material to create the desired shape. Laser additive manufacturing, on the other hand, only uses the material needed to create the desired shape, reducing waste and improving efficiency.

Applications of Laser Additive Manufacturing

Laser additive manufacturing has a wide range of applications in various industries, including aerospace, automotive, medical, and jewelry. In the aerospace industry, laser additive manufacturing is used to create lightweight parts that are strong and durable. In the medical industry, it is used to create custom implants and prosthetics that are tailored to the patient’s specific needs.

In the jewelry industry, laser additive manufacturing is used to create intricate designs and patterns that would be impossible to produce using traditional methods. It is also used to create custom pieces that are unique to each customer.

The Future of Laser Additive Manufacturing

The future of laser additive manufacturing looks promising. With advancements in technology, it is becoming more efficient and cost-effective, making it a viable option for mass production. As more industries adopt this technology, it is likely that we will see new applications and innovations in the field.

In conclusion, laser additive manufacturing is a rapidly growing technology that has many benefits over traditional manufacturing methods. It has the ability to create complex geometries with high precision and accuracy, reduce waste, and has a wide range of applications in various industries. As technology continues to advance, we can expect to see even more innovations in this field.

Frequently Asked Questions

Here are some common questions and answers about Laser Additive Manufacturing.

What is Laser Additive Manufacturing?

Laser Additive Manufacturing (LAM) is a manufacturing process that uses a laser to melt and fuse layers of material together to create a three-dimensional object. This process is also known as 3D printing or additive manufacturing. LAM is commonly used to create complex geometries that are difficult or impossible to produce using traditional manufacturing methods.

The LAM process involves the use of a computer-aided design (CAD) model to guide the laser and create the desired shape. The laser melts the material and fuses it with the previous layer, building up the object layer by layer until it is complete.

What materials can be used in Laser Additive Manufacturing?

A wide variety of materials can be used in Laser Additive Manufacturing, including metals, plastics, ceramics, and composites. The specific materials that can be used depend on the type of laser and the process parameters used. Some common materials used in LAM include titanium, stainless steel, aluminum, and various polymers.

In recent years, there has been a lot of research into using LAM to create parts from advanced materials such as high-temperature alloys, superalloys, and even biological materials like bone and cartilage.

What are the advantages of Laser Additive Manufacturing?

Laser Additive Manufacturing offers several advantages over traditional manufacturing methods. One of the biggest advantages is the ability to create complex geometries that would be difficult or impossible to produce using traditional methods. LAM also allows for the creation of customized parts without the need for expensive tooling.

Another advantage of LAM is the ability to produce parts with improved mechanical properties. The process can produce parts with a fine microstructure that can improve strength, ductility, and other properties. LAM can also reduce material waste and lead times, making it a more efficient process.

What are the limitations of Laser Additive Manufacturing?

Despite its many advantages, Laser Additive Manufacturing does have some limitations. One of the biggest limitations is the size of the parts that can be produced. Most LAM machines have a limited build volume, which can make it difficult to produce large parts. LAM also tends to be slower than traditional manufacturing methods, which can make it less suitable for high-volume production.

Another limitation of LAM is the cost. While the cost of LAM has been decreasing in recent years, it is still more expensive than some traditional manufacturing methods. This can make it less suitable for low-volume production runs or for producing simple parts that can be made using other methods.

What industries use Laser Additive Manufacturing?

Laser Additive Manufacturing is used in a variety of industries, including aerospace, automotive, medical, and consumer products. In the aerospace industry, LAM is used to produce lightweight parts with complex geometries. In the medical industry, LAM is used to create customized implants and surgical tools.

LAM is also used in the automotive industry to produce parts with improved performance and to reduce weight. In the consumer products industry, LAM is used to create customized jewelry and other products. As the technology continues to improve, it is likely that LAM will become more widely used in other industries as well.

In conclusion, Laser Additive Manufacturing (LAM) is a highly innovative manufacturing process that is transforming the way we produce goods. By using a laser to fuse materials layer by layer, LAM allows us to create complex and intricate designs that were once impossible to achieve using traditional manufacturing methods.

Not only does LAM enable the creation of highly customized products, but it also reduces waste by using only the exact amount of materials needed for production. This makes it a more sustainable option compared to traditional manufacturing methods that often result in excess material waste.

As technology continues to advance, we can expect to see even more applications for Laser Additive Manufacturing in various industries. From aerospace to medical devices, LAM has the potential to revolutionize the way we design and produce products, making it an exciting field to watch in the years to come.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com