Table of Contents

Low pressure die casting is a popular method used to produce high-quality metal components with a high level of accuracy and consistency. This process involves injecting molten metal into a pre-designed mold at low pressure, resulting in a product with minimal porosity and excellent surface finish.

Compared to other casting methods, low pressure die casting is known for its ability to produce complex geometries with thin walls and intricate details. This makes it an ideal choice for manufacturing parts used in the automotive, aerospace, and medical industries. In this article, we will delve deeper into the process of low pressure die casting and explore its advantages and limitations.

Understanding Low Pressure Die Casting

Low pressure die casting is a popular metal casting process that involves the injection of molten metal into a preheated, reusable steel die under low pressure. This process is commonly used for the production of high-quality, complex metal parts that require tight tolerances and excellent surface finishes. In this article, we will explore the process of low pressure die casting in detail, its benefits, and its applications.

How Low Pressure Die Casting Works

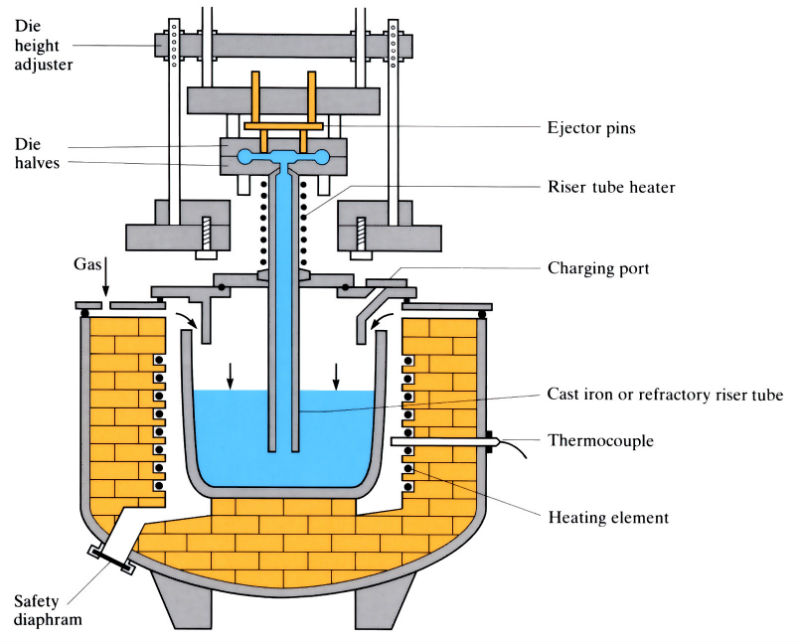

Low pressure die casting is a process that begins with the preparation of the mold. The mold is preheated to a specific temperature and coated with a release agent to prevent sticking. The molten metal is then injected into the mold cavity under low pressure (typically 10-100 kPa) using a refractory tube. The metal fills the cavity and solidifies, forming the desired shape of the part. Once the metal has cooled and solidified, the die is opened, and the part is removed.

The low pressure die casting process offers several advantages over other casting processes. For example, the low pressure used in this process ensures that the molten metal is not exposed to the atmosphere, preventing oxidation and ensuring a high-quality surface finish. Additionally, the low pressure used in this process means that the mold can be made of steel, which is more durable and longer-lasting than other materials used in casting.

The Benefits of Low Pressure Die Casting

Low pressure die casting offers several benefits, including excellent surface finishes, tight tolerances, and the ability to produce complex parts with thin walls. The low pressure used in this process ensures that the molten metal is not exposed to the atmosphere, preventing oxidation and ensuring a high-quality surface finish. Additionally, the use of steel molds in this process means that the molds are more durable and longer-lasting than other materials used in casting.

Another benefit of low pressure die casting is the ability to produce complex parts with thin walls. The low pressure used in this process allows the molten metal to flow into intricate shapes and cavities, resulting in parts with thin walls and complex shapes that cannot be produced using other casting processes.

The Applications of Low Pressure Die Casting

Low pressure die casting is commonly used in the automotive industry for the production of engine blocks, cylinder heads, and other parts that require high strength and excellent surface finishes. It is also used in the aerospace industry for the production of turbine blades and other parts that require tight tolerances and excellent surface finishes.

Additionally, low pressure die casting is used in the production of consumer goods such as cookware, lighting fixtures, and other decorative items that require high-quality surface finishes and complex shapes.

Low Pressure Die Casting vs. Other Casting Processes

Low pressure die casting offers several advantages over other casting processes, including high-quality surface finishes, tight tolerances, and the ability to produce complex parts with thin walls. In contrast, sand casting, which is another popular casting process, is less expensive but produces parts with rougher surface finishes and thicker walls.

Investment casting, another popular casting process, produces high-quality surface finishes and tight tolerances but is more expensive than low pressure die casting. Additionally, investment casting is limited in the size and complexity of the parts that can be produced.

Conclusion

Low pressure die casting is a popular metal casting process that offers several benefits, including excellent surface finishes, tight tolerances, and the ability to produce complex parts with thin walls. It is commonly used in the automotive and aerospace industries, as well as in the production of consumer goods. If you’re looking for a casting process that can produce high-quality, complex parts, low pressure die casting may be the right choice for your application.

Frequently Asked Questions

Here are some commonly asked questions about Low Pressure Die Casting.

What is Low Pressure Die Casting?

Low Pressure Die Casting is a casting process that uses a low-pressure injection of molten metal into a permanent metal mold or die to produce high-quality and accurate castings. This process is widely used in the automotive, aerospace, and other industries because it produces parts with excellent surface finish, dimensional accuracy, and mechanical properties.

The process involves the use of a furnace to melt the metal, which is then poured into a holding furnace. The molten metal is then injected into the mold under low pressure, and the mold is held under pressure until the metal solidifies. Once the metal has solidified, the mold is opened, and the casting is removed.

What are the advantages of Low Pressure Die Casting?

Low Pressure Die Casting has several advantages over other casting methods such as sand casting or investment casting. One of the key advantages is that it produces parts with excellent dimensional accuracy and surface finish. This means that the parts require little or no machining, which reduces the overall cost of production.

Another advantage of Low Pressure Die Casting is that it produces parts with excellent mechanical properties. The process ensures that the metal is evenly distributed throughout the casting, which results in parts that are strong and durable. Low Pressure Die Casting is also a highly repeatable process, which means that parts can be produced with consistent quality and accuracy.

What materials are suitable for Low Pressure Die Casting?

Low Pressure Die Casting is suitable for a wide range of materials, including aluminum, magnesium, and copper-based alloys. These materials are commonly used in the automotive and aerospace industries because they offer a good balance of strength, weight, and cost-effectiveness.

When choosing a material for Low Pressure Die Casting, it is important to consider the specific requirements of the part, including its strength, weight, and durability. The material should also be easy to cast and machine, and it should be readily available in the market.

What are the limitations of Low Pressure Die Casting?

Despite its many advantages, Low Pressure Die Casting has some limitations that need to be considered. One of the main limitations is the size of the parts that can be produced. The process is best suited for small to medium-sized parts, and it may not be suitable for large parts.

Another limitation of Low Pressure Die Casting is the cost of the equipment and tooling. The process requires specialized equipment, including a furnace, a holding furnace, and a low-pressure casting machine. Additionally, the tooling for the mold can be expensive to produce, especially for complex parts.

How does Low Pressure Die Casting compare to other casting methods?

Low Pressure Die Casting is often compared to other casting methods such as sand casting or investment casting. Compared to sand casting, Low Pressure Die Casting offers better dimensional accuracy, surface finish, and mechanical properties. It also requires less finishing work and produces less waste.

When compared to investment casting, Low Pressure Die Casting offers similar benefits in terms of dimensional accuracy and surface finish. However, it is more cost-effective for small to medium-sized parts and offers better mechanical properties.

Low pressure die casting is a manufacturing process used to produce high-quality metal parts with intricate designs. It is a cost-effective method used by many industries to create complex metal parts, especially in the automotive and aerospace industries. In this process, molten metal is injected into a mold at low pressure, which helps to reduce air entrapment and porosity in the final product.

In conclusion, low pressure die casting is an excellent manufacturing process for creating intricate metal parts with high precision and accuracy. It is a cost-effective method that is widely used in various industries to produce complex parts. The process helps to reduce air entrapment and porosity, resulting in high-quality parts that meet the desired specifications. If you’re looking for a reliable and efficient method to create metal parts, low pressure die casting is definitely worth considering.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com