Table of Contents

Magnesium die casting is a manufacturing process that involves injecting molten magnesium into a steel mold to create complex parts with high precision and accuracy. This versatile process is widely used in a range of industries, including automotive, aerospace, electronics, and medical.

Magnesium die casting offers numerous benefits, including lightweight construction, excellent strength-to-weight ratio, and exceptional corrosion resistance. Additionally, it is an eco-friendly process that uses minimal resources and generates minimal waste, making it an ideal option for companies looking to reduce their environmental impact.

H2: What is Magnesium Die Casting?

Magnesium die casting is a manufacturing process that involves injecting molten magnesium into a mold cavity under high pressure. The process is used to produce complex and intricate parts with high dimensional accuracy and surface finish. The lightweight and durable properties of magnesium make it an excellent choice for a variety of applications across different industries.

H3: The Process of Magnesium Die Casting

Magnesium die casting involves several steps, including:

1. Mold Design and Fabrication: The first step in magnesium die casting is to create a mold cavity that matches the desired shape of the part. The mold can be made of steel, aluminum, or other materials depending on the complexity and volume of the part.

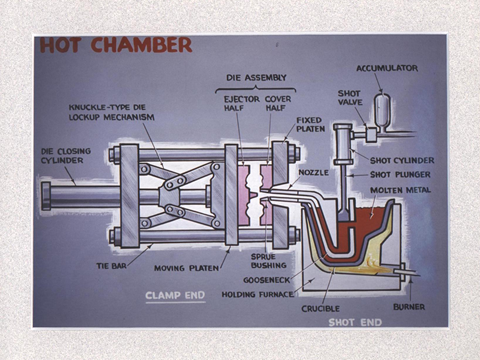

2. Melting and Injection: The next step is to melt the magnesium alloy in a furnace and inject it into the mold cavity under high pressure. The pressure helps to fill all the details of the mold and ensure a high-quality finish.

3. Cooling and Ejection: Once the part has been cast, it is cooled down to solidify the magnesium and then ejected from the mold. The part is then trimmed and finished to remove any excess material or rough edges.

H3: Benefits of Magnesium Die Casting

Magnesium die casting offers several benefits over other manufacturing processes, including:

1. Lightweight: Magnesium is one of the lightest metals available, making it an ideal choice for parts that need to be lightweight and strong, such as automotive components.

2. High Strength-to-Weight Ratio: Magnesium has a high strength-to-weight ratio, making it ideal for applications that require strength and durability without adding extra weight.

3. High Dimensional Accuracy: Magnesium die casting can produce parts with high dimensional accuracy and surface finish, making it an ideal choice for parts that require tight tolerances.

4. Cost-Effective: Magnesium die casting is a cost-effective manufacturing process, as it can produce complex parts in large quantities with minimal waste.

H3: Magnesium Die Casting Vs Other Processes

Magnesium die casting offers several advantages over other manufacturing processes, including:

1. Injection Molding: Magnesium die casting can produce parts with a higher strength-to-weight ratio and better dimensional accuracy than injection molding.

2. Sand Casting: Magnesium die casting can produce parts with a better surface finish and tighter tolerances than sand casting.

3. Machining: Magnesium die casting can produce complex parts with less waste and lower cost than machining.

H3: Applications of Magnesium Die Casting

Magnesium die casting is used in a variety of applications across different industries, including:

1. Automotive: Magnesium die casting is used to produce components such as engine blocks, transmission cases, and steering wheels.

2. Aerospace: Magnesium die casting is used to produce parts such as aircraft seats, brackets, and housings.

3. Electronics: Magnesium die casting is used to produce components such as laptop frames, cell phone cases, and camera bodies.

4. Medical: Magnesium die casting is used to produce components such as surgical instruments, prosthetic devices, and dental implants.

H3: Conclusion

Magnesium die casting is a versatile and cost-effective manufacturing process that produces high-quality parts with excellent dimensional accuracy and surface finish. It offers several benefits over other manufacturing processes and can be used in a variety of applications across different industries. With its lightweight and durable properties, magnesium die casting is an ideal choice for parts that require strength and durability without adding extra weight.

Frequently Asked Questions

Magnesium Die Casting is a process used in manufacturing where molten magnesium is poured into a mold to create a desired shape. This process is commonly used in the production of automotive and aerospace parts due to magnesium’s lightweight properties and excellent strength-to-weight ratio.

What is Magnesium Die Casting?

Magnesium Die Casting is a manufacturing process in which a molten magnesium alloy is injected into a mold under high pressure to produce a specific shape or design. The process involves the use of specialized machines and tools to ensure accuracy and consistency. Magnesium Die Casting is commonly used in the production of automotive and aerospace parts due to magnesium’s lightweight and strong properties.

The process involves several stages, including mold creation, melting and injection of the magnesium alloy, and post-processing to remove excess material and refine the final product. Magnesium Die Casting is a cost-effective method of producing complex parts with high levels of accuracy and consistency.

What are the Advantages of Magnesium Die Casting?

Magnesium Die Casting offers several advantages over other manufacturing processes. One of the main advantages is the lightweight nature of magnesium, which makes it an ideal material for producing parts that need to be strong and lightweight. Magnesium also has excellent strength-to-weight ratio, making it perfect for applications where weight reduction is critical.

Another advantage of Magnesium Die Casting is the ability to produce complex shapes and designs with high levels of accuracy and consistency. This process allows for the creation of parts with intricate details and tight tolerances, making it a popular choice for the production of automotive and aerospace parts.

What are the Applications of Magnesium Die Casting?

Magnesium Die Casting has a wide range of applications in various industries. It is commonly used in the production of automotive and aerospace parts due to its lightweight properties and excellent strength-to-weight ratio. Magnesium Die Casting is also used in the production of electronic and communication equipment, as well as sporting goods and medical devices.

The use of Magnesium Die Casting is increasing in popularity due to its ability to produce complex shapes and designs with high levels of accuracy and consistency. This process is also cost-effective, making it an ideal choice for large-scale production of parts and components.

What are the Challenges of Magnesium Die Casting?

Magnesium Die Casting is not without its challenges. One of the main challenges is the high reactivity of magnesium, which can lead to issues with corrosion and oxidation if not properly handled. This requires the use of specialized equipment and techniques to ensure proper handling and processing of the magnesium alloy.

Another challenge of Magnesium Die Casting is the difficulty in controlling the thickness of the walls of the part being produced. This can result in variations in the final product and may require additional post-processing to achieve the desired thickness and quality.

What is the Future of Magnesium Die Casting?

The future of Magnesium Die Casting looks promising, with increased demand for lightweight and strong materials in various industries. Advances in technology and materials science are also leading to the development of new magnesium alloys with improved properties, making it an even more attractive option for manufacturing complex parts and components.

The use of Magnesium Die Casting is also being explored in new areas, such as renewable energy and electric vehicles, where weight reduction is critical for performance and efficiency. As the demand for lightweight and strong materials continues to grow, Magnesium Die Casting is expected to play an increasingly important role in the manufacturing industry.

In conclusion, magnesium die casting is a highly efficient and popular manufacturing process used in a range of industries. This technique involves the melting of magnesium alloys and injecting the molten material into custom molds to create complex shapes and structures. The result is a lightweight, strong and durable product that can be used for a wide range of applications.

With its excellent mechanical properties, magnesium die casting is becoming increasingly popular in the automotive, aerospace, and electronics industries. The process is highly customizable, allowing manufacturers to produce components that meet specific design requirements. This means that magnesium die casting is an ideal solution for creating intricate and detailed components that are not possible to produce using traditional manufacturing methods.

Overall, magnesium die casting is an important and innovative manufacturing process that offers numerous benefits over other methods. With its exceptional strength-to-weight ratio, flexibility, and cost-effectiveness, it is no wonder that more and more industries are turning to this technique to produce high-quality products that meet their unique needs.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com