Table of Contents

Plastic injection molding is a manufacturing process used to create a variety of plastic products. It involves melting plastic pellets and injecting the molten plastic into a mold, where it cools and solidifies into the desired shape. This process is widely used in industries such as automotive, medical, and consumer goods.

By using plastic injection molding, manufacturers can create complex and intricate designs with high accuracy and consistency. It also allows for mass production, making it an efficient and cost-effective method for producing large quantities of plastic products. In this article, we will explore the basics of plastic injection molding and how it works.

What is Plastic Injection Molding?

Plastic injection molding is a popular manufacturing process that involves injecting molten plastic into a mold or cavity. This process is widely used to produce a wide range of plastic parts and products, from toys and household items to complex automotive and aerospace components.

How Does Plastic Injection Molding Work?

Plastic injection molding involves several steps, including:

Step 1: Design and Prototyping

The first step in plastic injection molding is to design the part or product that you want to create. This design is typically created using computer-aided design (CAD) software. Once the design is finalized, a prototype is created to test the design and ensure that it meets the required specifications.

Step 2: Mold Creation

Once the design and prototype are finalized, the mold is created. This mold is typically made of steel or aluminum and is precision-machined to the exact specifications of the part or product being produced.

Step 3: Injection Molding

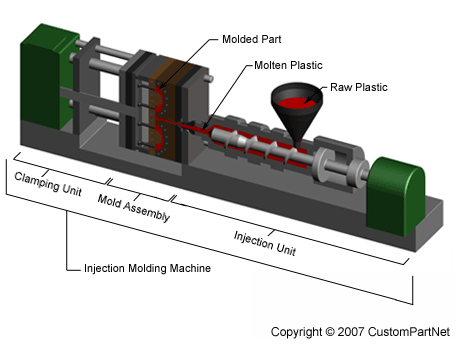

The next step is to inject molten plastic into the mold. This is done using an injection molding machine, which heats the plastic to a molten state and then injects it into the mold.

Step 4: Cooling and Ejection

After the plastic has been injected into the mold, it is allowed to cool and solidify. Once it has solidified, the mold is opened and the finished part or product is ejected.

What Are the Benefits of Plastic Injection Molding?

There are several benefits to using plastic injection molding for manufacturing plastic parts and products, including:

High Efficiency and Precision

Plastic injection molding is a highly efficient and precise manufacturing process. It allows for the production of large quantities of identical parts with very high precision and accuracy.

Wide Range of Materials

Plastic injection molding can be used with a wide range of plastic materials, including commodity plastics like polyethylene and polystyrene, as well as engineering plastics like nylon and polycarbonate.

Low Cost

Plastic injection molding is a relatively low-cost manufacturing process, especially when compared to other manufacturing processes like machining or casting.

Plastic Injection Molding Vs Other Manufacturing Processes

While plastic injection molding has many benefits, it is not always the best manufacturing process for every situation. Here are some of the key differences between plastic injection molding and other manufacturing processes:

Plastic Injection Molding Vs Machining

Machining is a manufacturing process that involves removing material from a solid block of material to create a part or product. While machining can be used to create highly precise parts, it is often more expensive and time-consuming than plastic injection molding.

Plastic Injection Molding Vs Casting

Casting is a manufacturing process that involves pouring molten metal or other materials into a mold to create a part or product. While casting can be used to create complex shapes and designs, it is often more expensive and time-consuming than plastic injection molding.

Plastic Injection Molding Vs 3D Printing

3D printing is a manufacturing process that involves creating a part or product by layering material on top of itself. While 3D printing can be used to create highly complex shapes and designs, it is often slower and less precise than plastic injection molding.

Conclusion

Plastic injection molding is a highly efficient and versatile manufacturing process that is widely used to produce a wide range of plastic parts and products. Whether you are producing toys or aerospace components, plastic injection molding can help you create high-quality products at a low cost.

Frequently Asked Questions

What is Plastic Injection Molding?

Plastic injection molding is the process of producing plastic parts by injecting molten plastic material into a mold. The molten plastic is injected at high pressure into a mold cavity, which is in the shape of the desired part. The plastic then cools and hardens, and the mold is opened to release the part.

Plastic injection molding is used to produce a wide range of products, from small parts like bottle caps and gears to larger parts like car body panels and medical devices. The process is popular in manufacturing because it is efficient, cost-effective, and allows for high volumes of production.

How does Plastic Injection Molding work?

Plastic injection molding works by melting plastic pellets in a hopper and then injecting them into a mold. The plastic material is heated to a high temperature and then injected into the mold at high pressure. The mold is then cooled, which causes the plastic to solidify and take on the shape of the mold.

The mold is designed with two halves, which are held together by a clamp. The cavity is the space between the two halves of the mold, and this is where the molten plastic is injected. The mold can be made from a variety of materials, including steel and aluminum, and can be designed to produce complex shapes with high accuracy.

What are the advantages of Plastic Injection Molding?

Plastic injection molding has many advantages over other manufacturing processes. It is a cost-effective way to produce high volumes of parts, and it allows for complex shapes to be produced with high accuracy. The molds used in plastic injection molding can also be reused, which further reduces the cost of production.

Another advantage of plastic injection molding is that it allows for a wide range of materials to be used. This means that parts can be produced with specific properties, such as strength, flexibility, or heat resistance. Plastic injection molding is also a fast process, with parts being produced in a matter of seconds or minutes.

What are the disadvantages of Plastic Injection Molding?

One of the main disadvantages of plastic injection molding is the cost of the molds. The molds can be expensive to produce, especially for complex parts. This means that there is a high initial investment required to start production.

Another disadvantage of plastic injection molding is that the process is not suitable for all types of materials. Some materials may not be able to withstand the high temperatures and pressures used in the process, which limits the range of materials that can be used.

What are the applications of Plastic Injection Molding?

Plastic injection molding is used in a wide range of applications across many industries. It is commonly used to produce parts for the automotive, medical, and consumer goods industries. Some examples of parts produced using plastic injection molding include electronic housings, automotive dashboards, and medical devices.

Plastic injection molding is also used to produce small parts, such as bottle caps and toys, as well as larger parts, such as panels for aircraft and boats. The process is versatile and can be used to produce parts of varying complexity and size, making it a popular choice for many manufacturers.

In conclusion, plastic injection molding is a versatile and efficient manufacturing process used to create a wide range of plastic products. From small components to large parts, this technology has revolutionized the way we produce plastic products. Its ability to produce intricate shapes and intricate designs with high precision and accuracy makes it an ideal choice for industries such as automotive, medical, and consumer goods.

Furthermore, the process is highly customizable, allowing manufacturers to produce parts in various colors, textures, and finishes. It also offers a cost-effective and eco-friendly solution for mass production, as it minimizes waste and reduces the need for manual labor.

Overall, plastic injection molding has become an indispensable technology in the manufacturing industry, providing endless possibilities for product design and development. As technology continues to evolve, we can expect to see even more innovative uses for this remarkable manufacturing process.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com