Table of Contents

CNC milling and turning are two of the most commonly used machining processes in the manufacturing industry. Both processes are used to produce precise parts and components for a variety of applications. However, there are significant differences between CNC milling and turning that distinguish one process from the other.

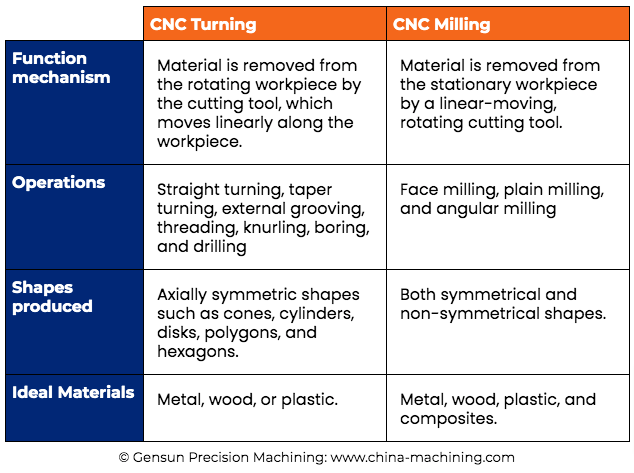

CNC milling involves the use of multi-point cutting tools to remove material from a workpiece. The cutting tools move in different directions on an X, Y, and Z axis to create the desired shape and finish. On the other hand, CNC turning involves the rotation of a workpiece while a cutting tool removes material from it. This process creates cylindrical parts with a variety of shapes and sizes. Understanding the differences between these two processes is crucial for choosing the right machining method for your specific needs.

CNC milling and turning are two popular machining processes used in the manufacturing industry. The main difference between them is the way the cutting tool removes material from the workpiece. In milling, the cutting tool rotates and moves along multiple axes to remove material, while in turning, the workpiece rotates and the cutting tool moves along a single axis to remove material. CNC milling is ideal for creating complex shapes, while turning is better suited for creating cylindrical shapes.

Understanding the Difference Between CNC Milling and Turning

CNC machining is a versatile manufacturing process that involves the use of computer-controlled machines to create precise and complex parts. CNC milling and turning are two of the most commonly used techniques in the industry. While both methods use similar technology and equipment, they differ in the way they create parts. Here’s a closer look at the difference between CNC milling and turning.

What is CNC Milling?

CNC milling involves the use of a milling machine to remove material from a workpiece. The machine uses a rotating tool to cut and shape the material as it spins. The milling machine can move the workpiece in multiple directions, allowing for precise cuts and complex shapes.

One of the main advantages of CNC milling is the ability to produce parts with high precision and accuracy. The computer-controlled machine ensures that each cut is made to the exact specifications, resulting in consistent and reliable parts. CNC milling is also ideal for creating parts with complex geometries, such as those with curves or irregular shapes.

Benefits of CNC Milling

– High precision and accuracy

– Ability to create complex shapes

– Consistent and reliable parts

CNC Milling Vs. Traditional Milling

Traditional milling involves manually controlling the movement of the cutting tool. This method is more time-consuming and less precise than CNC milling. CNC milling also allows for more complex geometries and can produce parts faster than traditional milling.

What is CNC Turning?

CNC turning involves the use of a lathe to create cylindrical parts. The lathe rotates the workpiece while a cutting tool removes material from the surface, shaping it into the desired form.

CNC turning is ideal for creating parts with cylindrical or circular shapes, such as shafts and valves. The process is also efficient, allowing for high-volume production of parts.

Benefits of CNC Turning

– Efficient production of cylindrical parts

– High-volume production capabilities

– Consistent and reliable parts

CNC Turning Vs. Manual Turning

Manual turning involves manually controlling the movement of the cutting tool. This method is time-consuming and less precise than CNC turning. CNC turning also allows for higher volume production and can produce parts faster than manual turning.

The Main Differences Between CNC Milling and Turning

While CNC milling and turning share some similarities, they differ in several key ways.

– CNC milling is used to create parts with complex geometries, while CNC turning is used for cylindrical parts.

– CNC milling uses a rotating tool to remove material from the workpiece, while CNC turning uses a stationary cutting tool.

– CNC milling can move the workpiece in multiple directions, while CNC turning only rotates the workpiece.

Which Method is Best?

The choice between CNC milling and turning depends on the specific needs of the project. If the part requires complex geometries or irregular shapes, CNC milling is the better option. If the part is cylindrical or requires high-volume production, CNC turning is the way to go.

Conclusion

In summary, CNC milling and turning are two of the most commonly used techniques in the manufacturing industry. While they share some similarities, they differ in the way they create parts. CNC milling is ideal for creating complex geometries, while CNC turning is efficient for producing cylindrical parts. By understanding the differences between these two methods, manufacturers can choose the best option for their specific needs.

Freequently Asked Questions

What is the Difference Between CNC Milling and Turning?

CNC milling and turning are two different machining processes that are used to create precise and complex parts. CNC milling involves using a rotating cutting tool to remove material from a stationary workpiece, while CNC turning involves rotating the workpiece while a stationary cutting tool removes material.

In CNC milling, the cutting tool can move in multiple directions and angles to create complex shapes and features, while in CNC turning, the cutting tool is limited to moving in a single axis. CNC milling is typically used for creating parts with complex shapes, while CNC turning is better suited for creating parts with cylindrical or symmetrical shapes.

What are the Advantages of CNC Milling?

CNC milling offers several advantages over other machining processes. One of the main advantages is the ability to create complex parts with high precision and accuracy. CNC milling also allows for faster production times and the ability to work with a wide range of materials. Additionally, CNC milling can be used to create parts with a variety of finishes and textures, making it a versatile option for many industries.

Another advantage of CNC milling is the ability to automate the process, which can lead to increased efficiency and cost savings. The use of CAD/CAM software allows for the creation of detailed designs and tool paths, which can be easily replicated across multiple parts.

What are the Advantages of CNC Turning?

CNC turning also offers several advantages over other machining processes. One of the main advantages is the ability to create parts with high precision and accuracy, particularly for parts with cylindrical or symmetrical shapes. CNC turning is also a faster process than many other machining processes, which can lead to faster production times and cost savings.

Another advantage of CNC turning is the ability to work with a wide range of materials, including metals, plastics, and composites. CNC turning also offers the ability to create parts with a variety of finishes and textures, making it a versatile option for many industries.

Which Process is Better Suited for Creating Complex Parts?

CNC milling is typically better suited for creating complex parts with intricate shapes and features. This is because the cutting tool can move in multiple directions and angles, allowing for greater flexibility and precision when creating complex geometries. CNC milling can also be used to create parts with a variety of finishes and textures.

While CNC turning is better suited for creating parts with cylindrical or symmetrical shapes, it is not as well-suited for creating complex geometries. However, CNC turning can still be used to create parts with intricate details and features, particularly for parts with a smaller diameter.

Which Process is Better Suited for High-Volume Production?

Both CNC milling and turning can be used for high-volume production, but the choice between the two processes will depend on the specific part being produced. CNC milling is typically better suited for creating more complex parts with intricate shapes and features, while CNC turning is better suited for creating parts with cylindrical or symmetrical shapes.

In general, CNC turning is a faster process than CNC milling, which can make it a better option for high-volume production of parts with simpler geometries. However, CNC milling can also be used for high-volume production, particularly for parts with complex geometries that require a high degree of precision and accuracy.

In conclusion, CNC milling and turning are two different machining processes that are commonly used in manufacturing. While both processes involve cutting material to create a final product, they differ in the orientation of the cutting tool and the movement of the workpiece. CNC milling involves cutting material using a rotating cutting tool that moves along multiple axes, while CNC turning involves cutting material using a stationary cutting tool that moves along a single axis.

It is important to understand the differences between CNC milling and turning to determine which process is best suited for a specific manufacturing project. Factors such as the shape of the part, the materials being used, and the required precision will all play a role in deciding which process to use.

Overall, CNC milling and turning are both valuable machining processes that have revolutionized the manufacturing industry. With the ability to create complex and precise parts quickly and efficiently, these processes have become essential tools for any modern manufacturing operation.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com