Table of Contents

- What is the Process of Aluminum Die Casting?

- Step 1: Designing the Mold

- Step 2: Creating the Mold

- Step 3: Melting the Aluminum

- Step 4: Injecting the Aluminum

- Step 5: Cooling the Mold

- Step 6: Ejecting the Part

- Step 7: Trimming and Finishing

- Step 8: Quality Control

- Step 9: Packaging and Shipping

- Step 10: Benefits of Aluminum Die Casting

- Aluminum Die Casting vs Other Processes

- Frequently Asked Questions

Aluminum die casting is a manufacturing process that involves using molten aluminum to produce intricate parts with high precision and accuracy. This process has gained popularity in various industries due to its ability to produce parts that are strong, durable, and lightweight.

When it comes to the process of aluminum die casting, there are several steps involved, including mold design, molten metal injection, cooling, and part ejection. Each step requires careful attention to detail and adherence to industry standards to ensure the final product meets the desired specifications. In this article, we will explore each step of the process in detail and provide insights into the benefits of aluminum die casting.

What is the Process of Aluminum Die Casting?

Aluminum die casting is a manufacturing process that involves the production of complex parts with high accuracy, repeatability, and speed. It is a process that uses molten aluminum that is forced under high pressure into a mold cavity. The mold cavity is designed to the shape and size of the part being produced. The molten aluminum solidifies and takes the shape of the mold cavity, creating a finished part that is ready for use. Here are the 10 steps involved in the process of aluminum die casting:

Step 1: Designing the Mold

The first step in the process of aluminum die casting is designing the mold. The mold is made of two steel plates that are designed to the exact shape and size of the part being produced. The mold is then machined to create a cavity that is the exact shape of the part being produced.

The mold is designed with the necessary features to allow the molten aluminum to flow into the cavity, including gates, runners, and vents. The design of the mold is critical to ensuring that the part is produced with the required accuracy and quality.

Step 2: Creating the Mold

Once the mold design is finalized, the mold is created. The mold is typically made of steel and is machined using computer-controlled equipment. The mold must be created with precision and accuracy to ensure that the parts produced are of high quality.

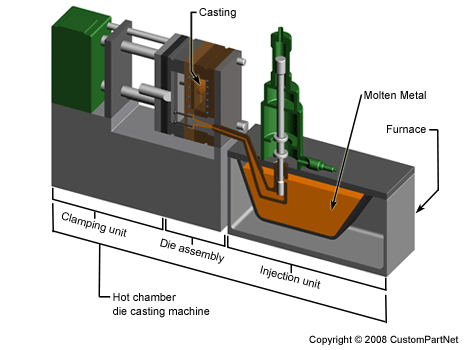

The mold is created in two halves, so that the part can be removed once it has been produced. The two halves of the mold are held together using a clamping unit.

Step 3: Melting the Aluminum

The next step in the process of aluminum die casting is melting the aluminum. The aluminum is melted in a furnace at a temperature of around 700°C to 750°C. The molten aluminum is then transferred to a holding furnace, where it is maintained at a consistent temperature.

Step 4: Injecting the Aluminum

Once the mold is ready and the aluminum has been melted, the molten aluminum is injected into the mold cavity. The aluminum is injected under high pressure, typically around 100 MPa to 200 MPa. The high pressure is necessary to ensure that the aluminum fills the cavity completely and that the part is produced with the required accuracy and quality.

Step 5: Cooling the Mold

After the aluminum has been injected into the mold, the mold is cooled. The cooling process is critical to ensuring that the part is produced with the required accuracy and quality. The mold is typically cooled using water, which is circulated through channels in the mold.

Step 6: Ejecting the Part

Once the mold has cooled, the clamping unit is released, and the two halves of the mold are separated. The finished part is ejected from the mold cavity using ejector pins. The part is removed carefully to avoid any damage or distortion.

Step 7: Trimming and Finishing

After the part has been ejected from the mold, it is typically trimmed and finished. The trimming process involves removing any excess material or flash that may have formed during the casting process. The finishing process may involve grinding, polishing, or other techniques to achieve the desired surface finish.

Step 8: Quality Control

Once the part has been trimmed and finished, it is inspected to ensure that it meets the required quality standards. The inspection process may involve visual inspection, dimensional measurement, or other techniques to ensure that the part is free from defects and meets the required specifications.

Step 9: Packaging and Shipping

Once the part has been inspected and approved, it is packaged and shipped to the customer. The packaging process is critical to ensuring that the part is protected during shipping and arrives at the customer in good condition. The part may be packaged in boxes, crates, or other containers, depending on the size and quantity of the parts being shipped.

Step 10: Benefits of Aluminum Die Casting

Aluminum die casting offers a number of benefits over other manufacturing processes. Some of the key benefits include:

- High accuracy and repeatability

- Fast production times

- Ability to produce complex shapes and designs

- Low cost of tooling

- Excellent surface finish and dimensional stability

Aluminum Die Casting vs Other Processes

Aluminum die casting is often compared to other manufacturing processes, such as injection molding and sand casting. Here are some of the key differences between aluminum die casting and these processes:

| Process | Advantages | Disadvantages |

|---|---|---|

| Aluminum Die Casting | High accuracy, fast production, low cost of tooling | Higher tooling cost than injection molding, limited material selection |

| Injection Molding | High accuracy, fast production, wide range of materials | High cost of tooling, limited design flexibility |

| Sand Casting | Low cost of tooling, good for large parts | Lower accuracy, slower production, limited design flexibility |

In conclusion, aluminum die casting is a complex and precise manufacturing process that offers many benefits over other manufacturing processes. Its ability to produce complex shapes and designs, along with its low cost of tooling and fast production times, make it a popular choice for producing high-quality parts.

Frequently Asked Questions

Aluminum die casting is a widely used manufacturing process for producing complex and intricate parts with high precision. Here are some frequently asked questions about the process:

What is aluminum die casting?

Aluminum die casting is a manufacturing process in which molten aluminum is injected under high pressure into a steel mold, also known as a die. The aluminum solidifies quickly, taking the shape of the mold, and is then ejected from the die. The process is used to produce complex and intricate parts with high precision and repeatability.

Aluminum die casting can be used to produce a wide range of parts for various industries, such as automotive, aerospace, electronics, and more. Some common examples of aluminum die cast parts include engine blocks, transmission cases, housings for electronics, and lighting fixtures.

What are the advantages of aluminum die casting?

Aluminum die casting offers several advantages over other manufacturing processes. Firstly, it allows for the production of complex and intricate parts with high precision and repeatability. It also offers good mechanical properties, such as high strength, durability, and corrosion resistance.

Aluminum die casting is a highly efficient process, with short cycle times and low material waste. It is also cost-effective for medium to high volume production runs. Finally, aluminum is a lightweight and recyclable material, making it a sustainable choice for manufacturing.

What are the steps involved in aluminum die casting?

The process of aluminum die casting involves several steps. Firstly, the die is closed and molten aluminum is injected into the die cavity under high pressure. The aluminum solidifies quickly and takes the shape of the cavity. The die is then opened and the part is ejected.

After ejection, the part is trimmed and any excess material is removed. The part may also undergo additional finishing processes, such as machining, polishing, or coating. Finally, the part is inspected for quality and any defects are identified and addressed.

What materials can be used for aluminum die casting?

Aluminum die casting is typically done using aluminum alloys, which are specially formulated to offer good mechanical properties, such as high strength, durability, and corrosion resistance. Some common aluminum alloys used in die casting include A380, A383, and A360.

Other materials, such as zinc and magnesium, can also be used for die casting. However, aluminum is preferred due to its lightweight, high strength, and good heat dissipation properties.

What factors affect the quality of aluminum die cast parts?

Several factors can affect the quality of aluminum die cast parts. These include the design of the part, the quality of the die, the properties of the aluminum alloy, the injection speed and pressure, and the cooling time and rate.

Proper design and tooling are critical for producing high-quality parts, as they help to ensure uniform filling of the die cavity and minimize defects. The properties of the aluminum alloy used, such as its composition and heat treatment, can also significantly impact the part’s quality. Finally, proper process control and monitoring are essential for ensuring consistency and repeatability of the process.

To sum up, aluminum die casting is a complex and intricate process that requires skilled professionals and specialized equipment. The process involves heating the aluminum to its melting point and injecting it into a mold under pressure to create a precise and accurate product.

This process has become popular in the manufacturing industry due to its ability to produce complex shapes with high precision and consistency. Additionally, aluminum die casting offers several advantages, including lightweight and durable products, cost-effectiveness, and the ability to produce large quantities of products quickly.

Overall, the process of aluminum die casting is an essential part of modern manufacturing, and its versatility and efficiency make it a popular choice for various industries. With advancements in technology, we can expect to see even more developments and improvements in the field of aluminum die casting in the future.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com