Table of Contents

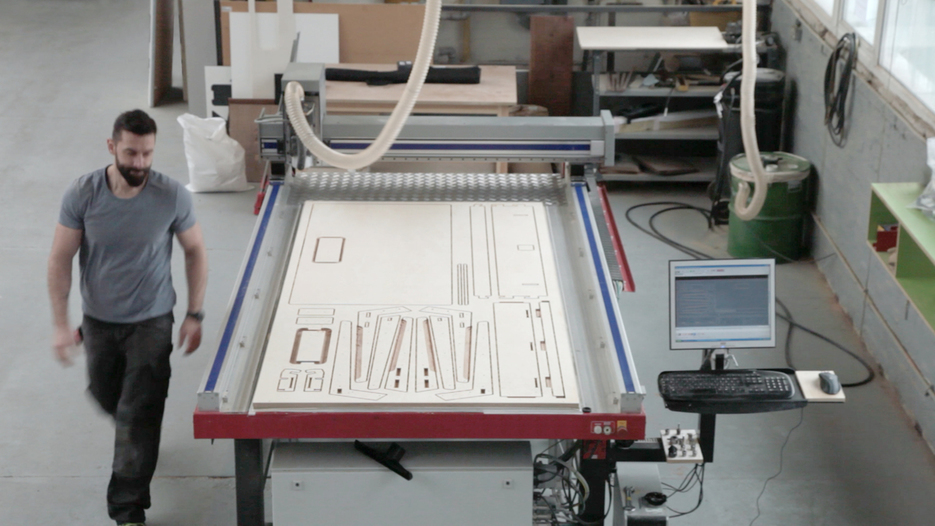

CNC machines have revolutionized the manufacturing industry by automating the cutting process. They have brought accuracy, speed, and efficiency to the production of various parts and components. But what materials can a CNC machine cut? This question is essential for both manufacturers and hobbyists looking to explore the capabilities of this technology.

CNC machines can cut a wide variety of materials, ranging from metals to plastics and wood. They can cut through hard materials like titanium, steel, and aluminum, as well as softer materials like foam, rubber, and PVC. However, the cutting speed, depth, and precision may vary depending on the material’s properties, hardness, and thickness. In this article, we will explore the different materials that CNC machines can cut and provide some tips to help you choose the right tool for your project.

What Materials Can a CNC Machine Cut?

CNC (Computer Numerical Control) machines are capable of cutting a wide range of materials, from metals to plastics and everything in between. CNC machines are an essential component of many modern manufacturing processes, allowing for precise and efficient cutting with minimal waste. In this article, we will explore the materials that CNC machines can cut and the benefits of using these machines for precision cutting.

Metals

CNC machines are often used to cut metals, including steel, aluminum, and brass. These machines are capable of cutting these materials with incredible precision, producing parts that are accurate to within a few thousandths of an inch. CNC machines are particularly useful for cutting complex shapes and parts that require high levels of accuracy and consistency.

One of the key benefits of using a CNC machine to cut metal is that it can reduce waste and improve efficiency. Because CNC machines are computer-controlled, they can optimize the cutting process to minimize material waste and maximize the yield of usable parts. Additionally, CNC machines can be programmed to run continuously, reducing the need for manual intervention and increasing productivity.

Plastics

CNC machines are also commonly used to cut plastics, including acrylic, polycarbonate, and PVC. These machines are particularly useful for cutting complex shapes and parts that require high levels of precision and accuracy. CNC machines can cut plastics with incredible accuracy, producing parts that are as precise as those cut from metal.

Using a CNC machine to cut plastics can offer a range of benefits, including improved efficiency and reduced material waste. Because CNC machines can optimize the cutting process, they can reduce the amount of material that is wasted during production. Additionally, CNC machines can be programmed to run continuously, reducing the need for manual intervention and increasing productivity.

Woods

CNC machines can also be used to cut a variety of woods, including plywood, MDF, and hardwoods. These machines are capable of producing precise and accurate cuts, making them ideal for cutting complex shapes and parts. CNC machines can also be used to create intricate designs and patterns in wood, adding a decorative element to the finished product.

Using a CNC machine to cut wood can offer a number of benefits, including increased precision, reduced waste, and improved efficiency. CNC machines can be programmed to optimize the cutting process, reducing the amount of material that is wasted during production. Additionally, CNC machines can be used to produce parts with a high level of accuracy, reducing the need for manual intervention and improving efficiency.

Glass

CNC machines can also be used to cut glass, including tempered and laminated glass. These machines are capable of producing precise and accurate cuts, making them ideal for cutting complex shapes and designs. CNC machines can be used to create intricate patterns and designs in glass, adding a decorative element to the finished product.

Using a CNC machine to cut glass can offer a range of benefits, including increased accuracy and reduced waste. CNC machines can be programmed to optimize the cutting process, reducing the amount of material that is wasted during production. Additionally, CNC machines can be used to produce parts with a high level of accuracy, reducing the need for manual intervention and improving efficiency.

Composites

CNC machines can also be used to cut composites, including fiberglass and carbon fiber. These materials are commonly used in the aerospace and automotive industries and require precise cutting to create complex shapes and components. CNC machines are capable of cutting these materials with incredible accuracy, producing parts that are as precise as those cut from metal.

Using a CNC machine to cut composites can offer a range of benefits, including increased precision, reduced waste, and improved efficiency. CNC machines can be programmed to optimize the cutting process, reducing the amount of material that is wasted during production. Additionally, CNC machines can be used to produce parts with a high level of accuracy, reducing the need for manual intervention and improving efficiency.

Stone

CNC machines can also be used to cut stone, including granite, marble, and slate. These machines are capable of producing precise and accurate cuts, making them ideal for cutting complex shapes and designs. CNC machines can be used to create intricate patterns and designs in stone, adding a decorative element to the finished product.

Using a CNC machine to cut stone can offer a range of benefits, including increased accuracy and reduced waste. CNC machines can be programmed to optimize the cutting process, reducing the amount of material that is wasted during production. Additionally, CNC machines can be used to produce parts with a high level of accuracy, reducing the need for manual intervention and improving efficiency.

Ceramics

CNC machines can also be used to cut ceramics, including porcelain and earthenware. These materials require precise cutting to create complex shapes and designs, making CNC machines an ideal choice for this type of work. CNC machines can be used to create intricate patterns and designs in ceramics, adding a decorative element to the finished product.

Using a CNC machine to cut ceramics can offer a range of benefits, including increased precision, reduced waste, and improved efficiency. CNC machines can be programmed to optimize the cutting process, reducing the amount of material that is wasted during production. Additionally, CNC machines can be used to produce parts with a high level of accuracy, reducing the need for manual intervention and improving efficiency.

Rubbers

CNC machines can also be used to cut rubbers, including natural and synthetic rubbers. These materials are commonly used in the automotive and industrial industries and require precise cutting to create complex shapes and components. CNC machines are capable of cutting these materials with incredible accuracy, producing parts that are as precise as those cut from metal.

Using a CNC machine to cut rubbers can offer a range of benefits, including increased precision, reduced waste, and improved efficiency. CNC machines can be programmed to optimize the cutting process, reducing the amount of material that is wasted during production. Additionally, CNC machines can be used to produce parts with a high level of accuracy, reducing the need for manual intervention and improving efficiency.

Benefits of Using a CNC Machine

Using a CNC machine to cut materials offers a range of benefits, including increased precision, reduced waste, and improved efficiency. CNC machines are capable of producing precise and accurate cuts, making them ideal for cutting complex shapes and designs. Additionally, CNC machines can be programmed to optimize the cutting process, reducing the amount of material that is wasted during production.

One of the key benefits of using a CNC machine is that it can reduce the need for manual intervention, improving efficiency and productivity. CNC machines can be programmed to run continuously, reducing the need for manual intervention and increasing productivity. Additionally, CNC machines can be used to produce parts with a high level of accuracy, reducing the need for manual intervention and improving efficiency.

CNC Machine vs. Traditional Cutting Methods

Using a CNC machine to cut materials offers a number of advantages over traditional cutting methods. Traditional cutting methods, such as manual cutting and sawing, require a high level of skill and can be time-consuming and inefficient. Additionally, traditional cutting methods can produce parts that are less precise and accurate than those produced by a CNC machine.

Using a CNC machine can offer a range of benefits, including increased precision, reduced waste, and improved efficiency. CNC machines can be programmed to optimize the cutting process, reducing the amount of material that is wasted during production. Additionally, CNC machines can be used to produce parts with a high level of accuracy, reducing the need for manual intervention and improving efficiency.

Conclusion

CNC machines are capable of cutting a wide range of materials, from metals to plastics and everything in between. These machines offer a range of benefits, including increased precision, reduced waste, and improved efficiency. Using a CNC machine to cut materials can help manufacturers produce high-quality parts with incredible accuracy, making them an essential component of modern manufacturing processes.

Frequently Asked Questions

Here are some common questions related to what materials a CNC machine can cut.

What materials can a CNC machine cut?

CNC machines are incredibly versatile and can cut a wide variety of materials, including metals, plastics, woods, and composites. In general, any material that can be cut with a traditional cutting tool can also be cut with a CNC machine.

Some of the most commonly machined materials include aluminum, steel, brass, and copper. Additionally, plastics like acrylic and polycarbonate are popular for their ease of machining and durability. CNC machines can also cut a range of woods, including hardwoods, softwoods, and plywood.

Can a CNC machine cut glass?

While it is technically possible to cut glass with a CNC machine, it is not a common practice. Glass is a brittle material that can be difficult to machine, and it can easily break or crack during the cutting process. Additionally, glass can be challenging to hold securely in a CNC machine, leading to inaccuracies and potentially dangerous situations.

Instead of cutting glass directly, many manufacturers use CNC machines to create molds or templates for glass cutting. This allows for more precise cuts and reduces the risk of breakage.

What about cutting ceramics or stone?

Like glass, ceramics and stone can be difficult to cut with a CNC machine. These materials are extremely hard and brittle, which can make them challenging to machine accurately. However, with the right tools and techniques, it is possible to cut these materials using a CNC machine.

Diamond-tipped tools are often used to cut ceramics and stone, as they are able to withstand the hardness of these materials. Additionally, water is often used as a coolant during the cutting process, as it can help to reduce the heat generated by the cutting tool and prevent damage to the material.

Can a CNC machine cut carbon fiber?

Yes, CNC machines can cut carbon fiber. Carbon fiber is a lightweight and incredibly strong material that is commonly used in aerospace, automotive, and sporting goods industries. While it can be challenging to cut due to its strength and brittleness, CNC machines are able to provide precise and accurate cuts.

To cut carbon fiber, manufacturers typically use diamond-tipped or carbide cutting tools, as these materials are able to withstand the hardness of the carbon fiber. Additionally, water is often used as a coolant to prevent the material from overheating during the cutting process.

Are there any materials that a CNC machine cannot cut?

While CNC machines are incredibly versatile, there are some materials that they are not able to cut. These include materials that are too hard or brittle, such as certain types of ceramics and glass. Additionally, some materials may be too soft or flexible, making them difficult to hold securely in the machine.

It’s important to note that even materials that can be cut with a CNC machine may require specialized cutting tools, techniques, and programming. This is why it’s important to work with an experienced CNC machining provider who can help determine the best approach for your specific project and material requirements.

In conclusion, CNC machines are a versatile tool that can cut a wide variety of materials, making them essential in many industries. From wood to metal and even plastics, these machines can handle almost any material with precision and accuracy. Whether you’re a woodworker, metal fabricator, or engineer, there’s a CNC machine that can help you bring your ideas to life.

It’s important to note that while CNC machines are capable of cutting many materials, they do have their limits. Some materials, such as tempered glass or certain ceramics, may be too brittle and prone to cracking. Additionally, certain materials such as carbon fiber or Kevlar may be too tough for some CNC machines to handle.

Overall, CNC machines are a valuable tool for anyone looking to cut materials with precision and accuracy. With the ability to handle a wide variety of materials, they are an essential tool in many industries and will continue to play an important role in manufacturing and fabrication for years to come.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com