Table of Contents

CNC routers are one of the most versatile and efficient machines available in the manufacturing industry. They can cut a wide variety of materials with precision and speed, making them a popular choice for businesses of all sizes. But what materials can a CNC router cut? In this article, we will explore the different types of materials that can be cut with a CNC router, from wood and plastics to metals and composites, and discuss the factors that determine their cutting suitability. So, let’s dive in and discover the world of CNC router cutting!

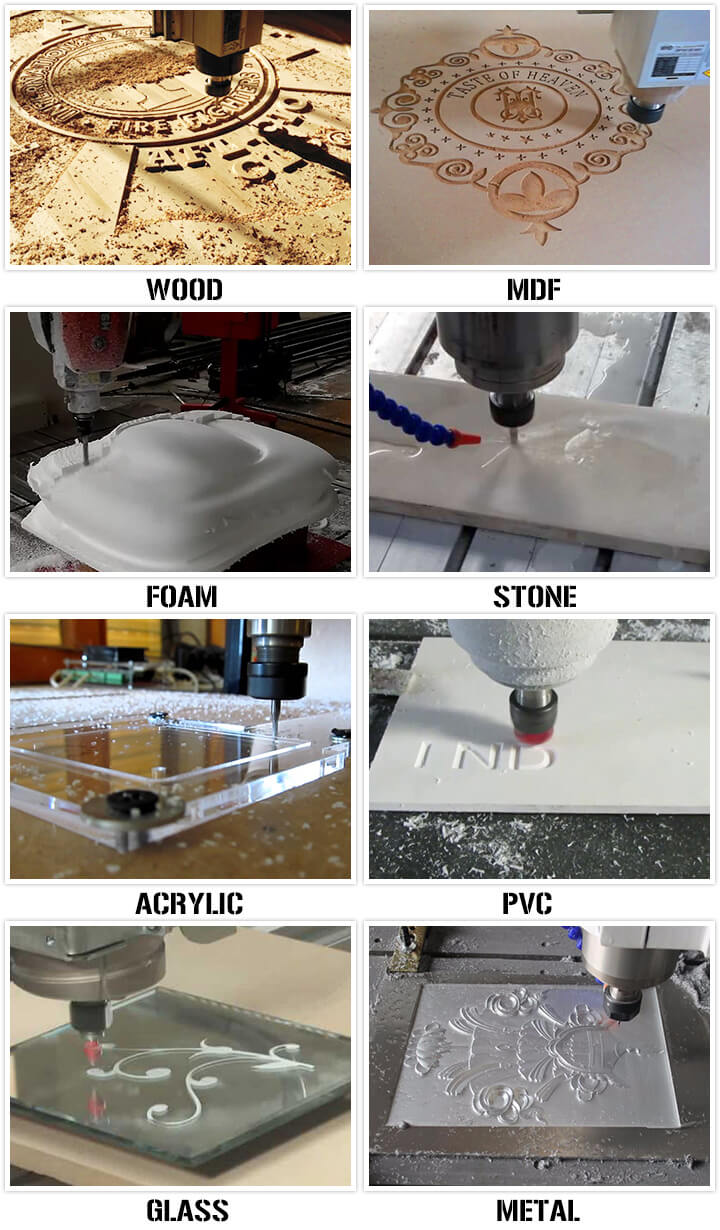

A CNC router can cut a wide range of materials such as wood, plastic, foam, aluminum, and composite materials. However, the specific materials a CNC router can cut depend on the power of the machine and the type of cutting tool used. It’s important to choose the right cutting tool and machine for the material you plan to cut to achieve the best results.

What Materials Can a CNC Router Cut?

CNC routers are powerful machines that use computer-controlled cutting tools to cut a wide range of materials with precision and accuracy. They are indispensable in many industries, from woodworking to metalworking, and can cut a variety of materials to produce high-quality finished products. In this article, we’ll explore the types of materials that a CNC router can cut and the benefits of using one.

1. Wood

Wood is one of the most popular materials that a CNC router can cut. CNC routers can cut different types of wood, including softwoods like pine and hardwoods like oak and maple. They can also cut engineered wood products like MDF, plywood, and particleboard. CNC routers can cut intricate designs and shapes into wood with precision and accuracy, making them ideal for woodworking projects.

One of the benefits of using a CNC router to cut wood is that it can produce high-quality finished products at a faster rate than traditional woodworking methods. CNC routers can also cut multiple pieces of wood with the same design, which is useful for mass production.

2. Plastics

CNC routers can also cut a variety of plastics, including acrylic, polycarbonate, and PVC. Plastics are ideal for CNC routing because they are lightweight, durable, and easy to work with. CNC routers can cut intricate designs and shapes into plastics, making them ideal for producing signage, displays, and other products.

One of the benefits of using a CNC router to cut plastics is that it can produce high-quality finished products with precision and accuracy. CNC routers can also cut multiple pieces of plastic with the same design, which is useful for mass production.

3. Metals

CNC routers can also cut a variety of metals, including aluminum, brass, copper, and stainless steel. Metals are ideal for CNC routing because they are strong and durable. CNC routers can cut intricate designs and shapes into metals, making them ideal for producing parts and components for various industries.

One of the benefits of using a CNC router to cut metals is that it can produce high-quality finished products with precision and accuracy. CNC routers can also cut multiple pieces of metal with the same design, which is useful for mass production.

4. Foam

CNC routers can also cut foam, including polystyrene and polyurethane foam. Foam is ideal for CNC routing because it is lightweight and easy to work with. CNC routers can cut intricate designs and shapes into foam, making them ideal for producing props, packaging, and insulation.

One of the benefits of using a CNC router to cut foam is that it can produce high-quality finished products with precision and accuracy. CNC routers can also cut multiple pieces of foam with the same design, which is useful for mass production.

5. Composites

CNC routers can also cut a variety of composites, including fiberglass and carbon fiber. Composites are ideal for CNC routing because they are lightweight and strong. CNC routers can cut intricate designs and shapes into composites, making them ideal for producing parts and components for various industries.

One of the benefits of using a CNC router to cut composites is that it can produce high-quality finished products with precision and accuracy. CNC routers can also cut multiple pieces of composites with the same design, which is useful for mass production.

6. Stone

CNC routers can also cut stone, including granite and marble. Stone is ideal for CNC routing because it is strong and durable. CNC routers can cut intricate designs and shapes into stone, making them ideal for producing countertops, monuments, and other products.

One of the benefits of using a CNC router to cut stone is that it can produce high-quality finished products with precision and accuracy. CNC routers can also cut multiple pieces of stone with the same design, which is useful for mass production.

7. Glass

CNC routers can also cut glass, including tempered glass and laminated glass. Glass is ideal for CNC routing because it is strong and durable. CNC routers can cut intricate designs and shapes into glass, making them ideal for producing custom glass products.

One of the benefits of using a CNC router to cut glass is that it can produce high-quality finished products with precision and accuracy. CNC routers can also cut multiple pieces of glass with the same design, which is useful for mass production.

8. Leather

CNC routers can also cut leather, including cowhide and suede. Leather is ideal for CNC routing because it is durable and flexible. CNC routers can cut intricate designs and shapes into leather, making them ideal for producing custom leather products.

One of the benefits of using a CNC router to cut leather is that it can produce high-quality finished products with precision and accuracy. CNC routers can also cut multiple pieces of leather with the same design, which is useful for mass production.

9. Rubber

CNC routers can also cut rubber, including natural rubber and synthetic rubber. Rubber is ideal for CNC routing because it is durable and flexible. CNC routers can cut intricate designs and shapes into rubber, making them ideal for producing custom rubber products.

One of the benefits of using a CNC router to cut rubber is that it can produce high-quality finished products with precision and accuracy. CNC routers can also cut multiple pieces of rubber with the same design, which is useful for mass production.

10. Other Materials

CNC routers can cut a variety of other materials, including cardboard, paper, and foam board. These materials are ideal for CNC routing because they are lightweight and easy to work with. CNC routers can cut intricate designs and shapes into these materials, making them ideal for producing packaging, displays, and other products.

One of the benefits of using a CNC router to cut these materials is that it can produce high-quality finished products with precision and accuracy. CNC routers can also cut multiple pieces of these materials with the same design, which is useful for mass production.

In conclusion, CNC routers are versatile machines that can cut a wide range of materials with precision and accuracy. From wood to metal to foam, CNC routers can produce high-quality finished products for various industries. Understanding the materials that a CNC router can cut can help you choose the right machine for your needs and produce high-quality finished products.

Freequently Asked Questions

As a professional writer, I am often asked about the capabilities of a CNC router. One common question is, “What materials can a CNC router cut?” Below are five questions and answers that will provide a better understanding of the materials that can be cut with this machine.

What is a CNC router?

A CNC router is a computer-controlled cutting machine that is used to cut a variety of materials. It is an extremely versatile machine that can be used to create complex designs and shapes.

The machine works by using a cutting tool that is attached to a spindle. The spindle is controlled by a computer, which allows the machine to cut the material with precision and accuracy.

What materials can a CNC router cut?

A CNC router can cut a wide range of materials, including wood, plastic, foam, and metal. The machine is capable of cutting both soft and hard materials, and can be used to create a variety of products.

Some of the most common materials that are cut with a CNC router include plywood, MDF, acrylic, and aluminum. However, the machine can also be used to cut more exotic materials such as carbon fiber and Kevlar.

What is the maximum thickness of material that can be cut with a CNC router?

The maximum thickness of material that can be cut with a CNC router depends on the size of the machine and the type of cutting tool that is being used. However, in general, most machines can cut materials up to 6 inches thick.

If you need to cut thicker materials, you may need to use a different type of cutting machine such as a plasma cutter or waterjet cutter.

What is the accuracy of a CNC router?

The accuracy of a CNC router depends on a number of factors, including the size of the machine, the type of cutting tool that is being used, and the complexity of the design. However, in general, most CNC routers are capable of cutting with an accuracy of +/- 0.001 inches.

This level of accuracy makes the CNC router an ideal machine for creating intricate designs and shapes.

How long does it take to cut a material with a CNC router?

The time it takes to cut a material with a CNC router depends on a number of factors, including the size of the machine, the type of cutting tool that is being used, and the complexity of the design. However, in general, most CNC routers are capable of cutting materials at a rate of 100 inches per minute.

This means that a simple design can be cut in a matter of minutes, while a more complex design may take several hours to complete.

In conclusion, a CNC router is a versatile tool that can cut a wide range of materials with high precision and accuracy. From wood to plastic, metal to foam, the possibilities are endless. With the right cutting bit and settings, a CNC router can produce intricate designs and shapes that would be difficult to achieve by hand.

However, it is important to note that not all materials can be cut with a CNC router. Some materials, such as glass and stone, require specialized equipment and techniques. It is also important to consider the thickness and hardness of the material before attempting to cut it with a CNC router.

Overall, a CNC router is a valuable tool for both hobbyists and professionals. With its ability to cut a variety of materials, it opens up a world of possibilities for creative projects and designs. As technology continues to advance, we can expect to see even more materials that can be cut with a CNC router in the future.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com