Hot die casting is a manufacturing process that involves pouring molten metal into a mold under high pressure. This process is ideal for producing complex and intricate geometric shapes with extreme accuracy and consistency. But what parts can you make with hot die casting? Let’s explore the possibilities!

From automotive engine blocks to aerospace components, hot die casting is used to manufacture a wide range of parts that require high strength, durability, and precision. With the ability to produce intricate details and shapes, this process is ideal for creating parts that may be difficult or impossible to produce with other manufacturing methods. So, whether you’re looking to produce small parts or large components, hot die casting is a versatile and reliable method for manufacturing high-quality parts.

What Parts Can You Make With Hot Die Casting?

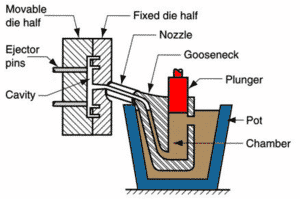

Hot die casting is a manufacturing process that involves injecting molten metal into a die to create a specific shape. This process has been used for centuries to create various parts and products. With advancements in technology, hot die casting has become even more versatile, allowing for the creation of complex parts with high precision. In this article, we will explore the parts that can be made with hot die casting.

Engine Parts

Hot die casting is commonly used to manufacture engine parts. These parts include cylinder heads, engine blocks, and pistons. The high precision and strength of the hot die casting process make it an ideal choice for these critical components. Additionally, hot die casting allows for the creation of intricate designs that are difficult to achieve with other manufacturing processes.

The benefits of hot die casting engine parts are numerous. Firstly, the process allows for the creation of lightweight parts that improve fuel efficiency. Additionally, hot die casting creates parts with high dimensional stability, reducing the risk of engine failure. Lastly, hot die casting is a cost-effective process, making it a popular choice for engine manufacturers.

Automotive Parts

Hot die casting is also commonly used to manufacture automotive parts. These parts include transmission housings, suspension components, and brake calipers. The high precision and strength of hot die casting make it an ideal choice for these critical components. Additionally, hot die casting allows for the creation of intricate designs that are difficult to achieve with other manufacturing processes.

The benefits of hot die casting automotive parts are numerous. Firstly, the process allows for the creation of lightweight parts that improve fuel efficiency. Additionally, hot die casting creates parts with high dimensional stability, reducing the risk of failure. Lastly, hot die casting is a cost-effective process, making it a popular choice for automotive manufacturers.

Consumer Electronics

Hot die casting is also used to manufacture parts for consumer electronics. These parts include laptop frames, smartphone cases, and tablet housings. The high precision and strength of hot die casting make it an ideal choice for these critical components. Additionally, hot die casting allows for the creation of intricate designs that are difficult to achieve with other manufacturing processes.

The benefits of hot die casting consumer electronics parts are numerous. Firstly, the process allows for the creation of lightweight parts that improve portability. Additionally, hot die casting creates parts with high dimensional stability, reducing the risk of malfunction. Lastly, hot die casting is a cost-effective process, making it a popular choice for electronics manufacturers.

Medical Equipment

Hot die casting is also used to manufacture parts for medical equipment. These parts include surgical instruments, prosthetics, and orthotics. The high precision and strength of hot die casting make it an ideal choice for these critical components. Additionally, hot die casting allows for the creation of intricate designs that are difficult to achieve with other manufacturing processes.

The benefits of hot die casting medical equipment parts are numerous. Firstly, the process allows for the creation of lightweight parts that improve portability. Additionally, hot die casting creates parts with high dimensional stability, reducing the risk of malfunction. Lastly, hot die casting is a cost-effective process, making it a popular choice for medical equipment manufacturers.

Aerospace Parts

Hot die casting is also used to manufacture parts for aerospace applications. These parts include brackets, engine components, and structural components. The high precision and strength of hot die casting make it an ideal choice for these critical components. Additionally, hot die casting allows for the creation of intricate designs that are difficult to achieve with other manufacturing processes.

The benefits of hot die casting aerospace parts are numerous. Firstly, the process allows for the creation of lightweight parts that improve fuel efficiency. Additionally, hot die casting creates parts with high dimensional stability, reducing the risk of failure. Lastly, hot die casting is a cost-effective process, making it a popular choice for aerospace manufacturers.

Industrial Parts

Hot die casting is also used to manufacture industrial parts. These parts include pump housings, valve bodies, and machine components. The high precision and strength of hot die casting make it an ideal choice for these critical components. Additionally, hot die casting allows for the creation of intricate designs that are difficult to achieve with other manufacturing processes.

The benefits of hot die casting industrial parts are numerous. Firstly, the process allows for the creation of lightweight parts that improve efficiency. Additionally, hot die casting creates parts with high dimensional stability, reducing the risk of failure. Lastly, hot die casting is a cost-effective process, making it a popular choice for industrial manufacturers.

Jewelry

Hot die casting can also be used to manufacture jewelry. The process allows for the creation of intricate designs and high-quality finishes. Additionally, hot die casting allows for the creation of lightweight jewelry.

The benefits of hot die casting jewelry are numerous. Firstly, the process allows for the creation of intricate designs that are difficult to achieve with other manufacturing processes. Additionally, hot die casting creates high-quality finishes that are durable and long-lasting. Lastly, hot die casting is a cost-effective process, making it a popular choice for jewelry manufacturers.

Benefits of Hot Die Casting

Hot die casting has numerous benefits for manufacturers. Firstly, it allows for the creation of complex designs with high precision. Additionally, hot die casting produces parts with high dimensional stability, reducing the risk of failure. Lastly, hot die casting is a cost-effective process, reducing manufacturing costs.

Hot Die Casting vs. Other Manufacturing Processes

Hot die casting has several advantages over other manufacturing processes. Firstly, it allows for the creation of complex designs with high precision. Additionally, hot die casting produces parts with high dimensional stability, reducing the risk of failure. Lastly, hot die casting is a cost-effective process, reducing manufacturing costs. Other manufacturing processes, such as forging and stamping, may not offer the same level of precision or cost-effectiveness.

Conclusion

Hot die casting is a versatile manufacturing process that can be used to create a wide range of parts and products. From engine components to jewelry, hot die casting offers numerous benefits, including high precision, dimensional stability, and cost-effectiveness. As technology continues to advance, hot die casting will likely become an even more popular choice for manufacturers looking to create high-quality parts with complex designs.

Frequently Asked Questions

Here are some common questions and answers about the parts that can be made with hot die casting:

What is hot die casting?

Hot die casting is a manufacturing process that involves injecting molten metal into a steel mold, also known as a die. The metal solidifies within the die and takes on the shape of the mold. This process is commonly used to produce high-volume, complex metal parts with tight tolerances.

Parts made through hot die casting can range from small components, such as automotive engine brackets, to large parts, such as aluminum housings for power tools. The process can produce parts made from a variety of metals, including aluminum, zinc, magnesium, and copper alloys.

What are the advantages of hot die casting?

Hot die casting offers several advantages over other metal manufacturing processes. One of the main benefits is the ability to produce complex, high-quality parts with tight tolerances. The process is also highly efficient, allowing for the production of large quantities of parts in a short amount of time.

Other advantages of hot die casting include the ability to use a wide range of metals and alloys, the ability to incorporate features such as threads and undercuts directly into the part, and the ability to produce parts with a smooth, finished surface without the need for additional finishing processes.

What types of parts are commonly made through hot die casting?

Hot die casting is commonly used to produce a wide range of metal parts, including automotive components, electronic housings, and parts for power tools and appliances. Other examples of parts made through hot die casting include bicycle frames, medical equipment, and hardware components.

The process is particularly well-suited for high-volume production of parts with complex shapes and features, as well as parts that require high strength and durability.

What factors affect the quality of parts produced through hot die casting?

Several factors can affect the quality of parts produced through hot die casting. One important factor is the quality of the die itself, including its design, construction, and maintenance. The temperature and pressure of the molten metal, as well as the speed and timing of the injection process, can also impact the quality of the finished part.

Other factors that can affect part quality include the choice of metal or alloy, the presence of impurities in the metal, and the use of any additional post-processing or finishing steps.

What industries use hot die casting?

Hot die casting is used in a wide range of industries, including automotive, aerospace, electronics, and consumer goods. The process is particularly well-suited for industries that require high-volume production of complex metal parts, as well as industries that require parts with high strength and durability.

Examples of products made using hot die casting include automotive engine parts, aerospace components, electronic housings, and hardware components for power tools and appliances.

In conclusion, hot die casting is a versatile manufacturing process that can create a variety of complex and intricate parts. It is commonly used in industries such as automotive, aerospace, and electronics to produce parts with high strength and precision.

One of the key advantages of hot die casting is its ability to produce parts with consistent quality and dimensional accuracy. This makes it an ideal process for mass production of components that require tight tolerances and precise specifications.

Additionally, hot die casting can be used to produce parts with a wide range of shapes and sizes, from small, intricate components to large, complex parts. This flexibility makes it a popular choice for manufacturers who need to create a diverse range of products.

Overall, hot die casting is a valuable manufacturing process that can help businesses achieve their production goals efficiently and effectively. By working with experienced die casting professionals, companies can create high-quality parts that meet their specific requirements and exceed their customers’ expectations.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com