Table of Contents

Hot die casting is a process that has been used for many years to create complex metal parts. The process involves melting metal and pouring it into a mold, where it cools and solidifies into the desired shape. But who actually uses hot die casting, and why is it so popular?

One of the biggest industries that relies on hot die casting is the automotive industry. Car manufacturers use this process to create everything from engine parts to suspension components. Other industries that use hot die casting include aerospace, defense, and medical equipment manufacturing. With its ability to produce high-quality, precision parts quickly and efficiently, it’s no wonder that hot die casting is such a popular choice among manufacturers.

Who Uses Hot Die Casting?

Hot die casting is a widely used process in the manufacturing industry for producing high-quality parts with excellent accuracy and consistency. The process involves injecting molten metal into a mold under high pressure, which solidifies and takes the shape of the mold. This technique is used by a range of industries for producing parts of different sizes, shapes, and complexities. In this article, we will explore who uses hot die casting and why.

Automotive Industry

The automotive industry is one of the largest users of hot die casting. The process is used for producing a wide range of components, including engine, transmission, and suspension parts. These components require high accuracy and consistency to ensure optimal performance and safety. Hot die casting provides the required precision and allows for the production of complex geometries that cannot be achieved through other manufacturing methods.

Hot die casting is also used for producing lightweight components that help improve fuel efficiency and reduce emissions. The process allows for the use of lightweight materials such as aluminum and magnesium, which have excellent strength-to-weight ratios. These materials are also highly recyclable, making them an environmentally friendly choice.

Aerospace Industry

The aerospace industry also relies heavily on hot die casting for producing critical components such as turbine blades, engine parts, and structural components. These components must withstand extreme temperatures, high pressures, and harsh environments. Hot die casting provides the required strength, durability, and precision to meet these demanding requirements.

Hot die casting is also used for producing lightweight components that help reduce the weight of aircraft and improve fuel efficiency. The use of lightweight materials such as titanium and aluminum alloys is essential for achieving these goals. Hot die casting allows for the production of complex geometries that are difficult to achieve through other manufacturing methods, making it an ideal choice for aerospace applications.

Medical Industry

The medical industry also uses hot die casting for producing a range of components, including implants, surgical instruments, and diagnostic equipment. These components require high accuracy and consistency to ensure optimal performance and patient safety. Hot die casting provides the required precision and allows for the production of complex geometries that cannot be achieved through other manufacturing methods.

Hot die casting is also used for producing components with unique properties such as biocompatibility, corrosion resistance, and antimicrobial properties. These properties are essential for medical applications and are achieved through the use of specialized materials such as titanium and stainless steel alloys.

Benefits of Hot Die Casting

Hot die casting offers several benefits over other manufacturing methods. Some of these benefits include:

- High accuracy and consistency

- Ability to produce complex geometries

- Ability to use lightweight materials

- Ability to produce components with unique properties

- Cost-effective for high-volume production

Hot Die Casting vs. Other Manufacturing Methods

Hot die casting offers several advantages over other manufacturing methods such as:

- Higher accuracy and consistency compared to sand casting and investment casting

- Ability to produce complex geometries that cannot be achieved through machining

- Lower tooling costs compared to forging and stamping

- Ability to use lightweight materials compared to machining and welding

- Cost-effective for high-volume production compared to machining and welding

Conclusion

Hot die casting is a widely used manufacturing process that offers several benefits over other methods. The process is used by a range of industries for producing high-quality parts with excellent accuracy and consistency. The automotive, aerospace, and medical industries are some of the largest users of hot die casting. The process allows for the production of lightweight components with unique properties that cannot be achieved through other manufacturing methods. Hot die casting is a cost-effective option for high-volume production and offers several advantages over other methods such as sand casting, investment casting, forging, stamping, machining, and welding.

Frequently Asked Questions

What is hot die casting?

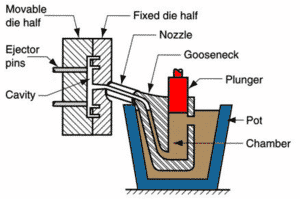

Hot die casting is a manufacturing process where molten metal is injected into a steel mold, called a die, under high pressure. This results in a highly accurate and precise shape of the metal part being produced. Hot die casting is commonly used for producing parts in large quantities and with consistent quality.

The process starts with the preparation of the die, which is then heated to a temperature above the melting point of the metal being used. The molten metal is then injected into the die under high pressure, and once cooled and solidified, the part is ejected from the die.

Who uses hot die casting?

Hot die casting is used by a wide range of industries, including automotive, aerospace, electronics, and consumer goods. This process is ideal for producing complex parts in large quantities with consistent quality, making it a popular choice for manufacturers.

The automotive industry, for example, uses hot die casting to produce parts such as engine blocks, transmission housings, and suspension components. The electronics industry uses this process for producing parts such as heat sinks, computer components, and mobile phone housings.

What are the advantages of hot die casting?

Hot die casting offers several advantages over other manufacturing processes. One of the main advantages is the ability to produce complex parts with high accuracy and precision, resulting in consistent quality.

Another advantage is the ability to produce parts in large quantities, making it an efficient and cost-effective manufacturing process. Hot die casting is also able to produce parts with a variety of surface finishes and can use a range of metals, including aluminum, zinc, and magnesium.

What are the limitations of hot die casting?

While hot die casting has many advantages, there are also some limitations to the process. One limitation is the size of the parts that can be produced, as the size of the die limits the size of the part.

Another limitation is the cost of the die, which can be expensive to produce, especially for small production runs. Additionally, hot die casting can produce parts with residual stresses, which can affect the strength and durability of the part.

How does hot die casting compare to other manufacturing processes?

Hot die casting is often compared to other manufacturing processes, such as injection molding and sand casting. While each process has its own advantages and disadvantages, hot die casting is typically used for producing parts with complex geometries and consistency in large quantities.

Injection molding, on the other hand, is used for producing parts with high accuracy and precision in smaller quantities. Sand casting is used for producing larger parts with lower accuracy and precision, but with lower tooling costs. Ultimately, the choice of manufacturing process depends on the specific needs of the part being produced.

In conclusion, hot die casting is a manufacturing process used by a wide range of industries. From automotive to aerospace, medical to electronics, and even consumer goods, hot die casting has become a popular choice for producing high-quality, complex metal parts.

One of the main reasons for its popularity is its efficiency. Hot die casting can produce large quantities of parts quickly and accurately, making it ideal for industries with high production demands. Additionally, it offers designers and engineers a level of flexibility, allowing them to create intricate designs that would otherwise be difficult to achieve.

Overall, hot die casting has proven to be a reliable and cost-effective method for producing metal parts. Its versatility and efficiency make it a valuable tool for a variety of industries, ensuring that it will continue to be used for years to come.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com