Table of Contents

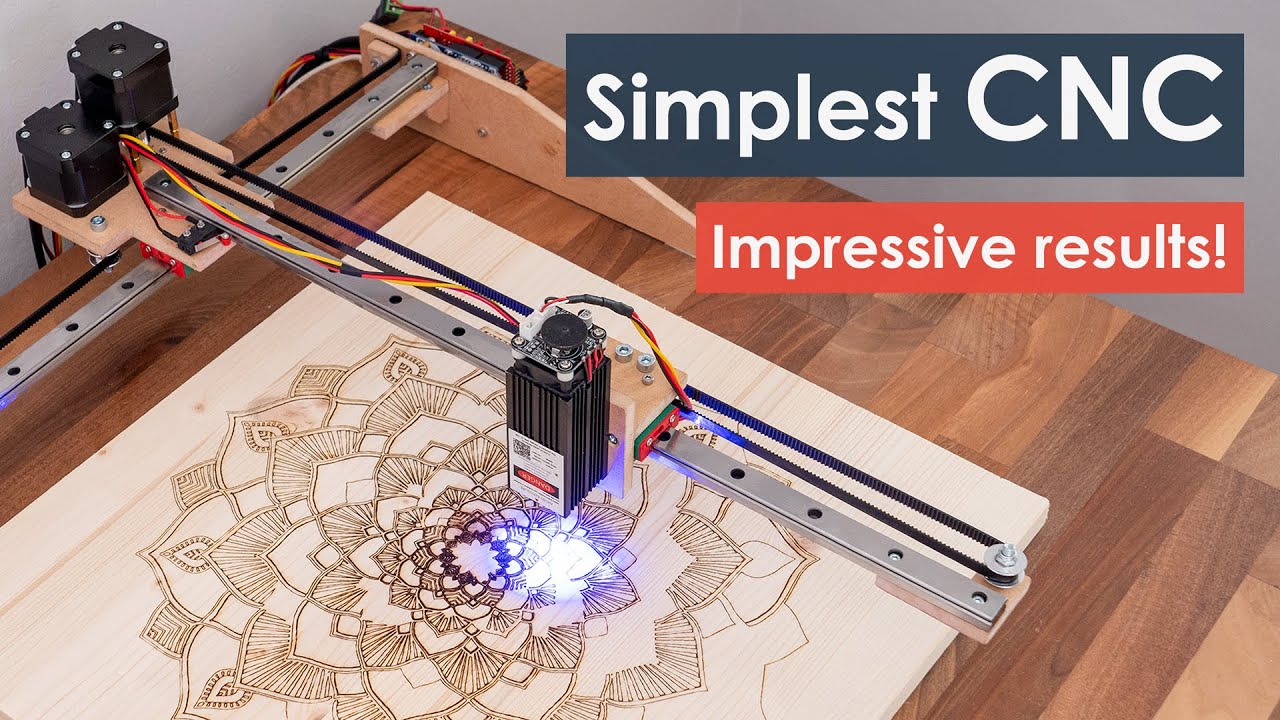

Have you ever wanted to build your own CNC machine but felt intimidated by the complex parts and components involved? What if we told you that it’s possible to build a CNC out of laser-cut materials, making the process much simpler and more accessible?

In this guide, we’ll walk you through the steps to build your own CNC using laser-cut materials. We’ll cover everything from designing and cutting the parts, to assembling and programming the machine. Whether you’re a beginner or an experienced maker, this project is a great way to learn new skills and create a useful tool for your workshop. So, let’s get started on building your very own CNC machine!

How to Build a CNC Out of Laser Cut Materials?

Building a CNC machine out of laser cut materials is a great way to create precise cuts and designs. Here’s a step-by-step tutorial:

1. Design your CNC machine using CAD software.

2. Export the design files as DXF files.

3. Send the DXF files to a laser cutting service.

4. Assemble the laser cut parts and add the necessary electronic components.

5. Install and configure the CNC software on your computer.

6. Test your CNC machine and make necessary adjustments.

With a little patience and attention to detail, you can build your own CNC machine using laser cut materials.

Building a CNC Out of Laser Cut Materials

If you’re looking to build a CNC machine, using laser cut materials can be a great option. Not only is it a cost-effective and efficient way to build a CNC, but you’ll also have the opportunity to customize it to your specific needs. In this article, we’ll go over the steps you’ll need to take to build your CNC out of laser cut materials.

Step 1: Designing Your CNC

The first step in building your CNC is designing it. This can be done using CAD software, such as AutoCAD or Fusion 360. In your design, you’ll need to include all of the necessary components, such as the frame, motors, and electronics. You’ll also need to decide on the size of your CNC.

Once you have your design, you can export it as a DXF file, which can be read by the laser cutter software.

Step 2: Cutting Your Materials

Next, you’ll need to cut your materials using a laser cutter. You’ll need to use materials that are suitable for laser cutting, such as acrylic or plywood. The laser cutter will follow the DXF file you created in the previous step to cut out all of the necessary components.

Benefits of Using Laser Cut Materials

- Cost-effective

- High precision

- Customizable

- Efficient

Step 3: Assembling Your CNC

Once you have all of your components, you’ll need to assemble your CNC. This will involve attaching the frame together, installing the motors and electronics, and connecting everything together. You’ll need to follow your design closely to ensure everything is assembled correctly.

Benefits of Building Your Own CNC

- Customizable

- Cost-effective

- High precision

- Opportunity to learn new skills

Step 4: Programming Your CNC

Once your CNC is assembled, you’ll need to program it. This will involve using software, such as Mach3 or GRBL, to control the movement of the CNC. You’ll need to input the necessary code to make your CNC move in the way you want it to.

Benefits of Programming Your Own CNC

- Customizable

- Ability to create complex designs

- Opportunity to learn new skills

Step 5: Testing Your CNC

Once your CNC is programmed, you’ll need to test it. This will involve running a test program to ensure everything is working correctly. You may need to make adjustments to your CNC to get it working properly.

Benefits of Testing Your CNC

- Ensures everything is working correctly

- Opportunity to make adjustments

- Ability to improve performance

Step 6: Using Your CNC

Once your CNC is tested and working correctly, you can start using it. You’ll be able to create a wide range of designs and products using your CNC. Make sure to follow all necessary safety precautions when using your CNC.

Benefits of Using Your Own CNC

- Customizable

- Ability to create complex designs

- Cost-effective

- Opportunity to start a business

Step 7: Maintaining Your CNC

To ensure your CNC continues to work properly, you’ll need to maintain it. This will involve regular cleaning, lubrication, and inspection. You’ll also need to replace any worn or damaged parts as necessary.

Benefits of Maintaining Your CNC

- Ensures your CNC continues to work properly

- Prevents breakdowns

- Helps to prolong the life of your CNC

Step 8: Conclusion

Building a CNC out of laser cut materials can be a great way to create a cost-effective and efficient machine. By following these steps, you’ll be able to design, cut, assemble, program, test, use, and maintain your CNC with ease. Whether you’re looking to start a business or create your own designs, a CNC is a valuable tool to have.

Freequently Asked Questions

In this section, we will answer some of the most commonly asked questions about building a CNC machine out of laser cut materials. Whether you are a beginner or a seasoned maker, this guide will help you get started on your CNC project.

What materials do I need to build a CNC machine?

Building a CNC machine out of laser cut materials requires a few essential components. You will need a laser cutter, CAD software, and access to a CNC router. Additionally, you will need to purchase a stepper motor, a power supply, and a controller board. You will also need to purchase linear bearings, lead screws, and a spindle motor. Finally, you will need to purchase a variety of nuts, bolts, and washers to assemble your CNC machine.

Before you begin building your machine, it’s important to do some research on the various types of CNC machines available. Each type has its own advantages and disadvantages, and you’ll want to choose the one that best suits your needs.

What software do I need to design my CNC machine?

Designing your CNC machine is an essential part of the building process. There are a variety of CAD software options available, including AutoCAD, SolidWorks, and Fusion 360. It’s important to choose a software that you are comfortable using and that has the features you need.

Once you have designed your machine, you will need to convert your CAD files into G-code, which is the language that the CNC machine understands. There are a variety of software options available for this, including CAM software like MeshCAM and Vectric Aspire.

How do I assemble my CNC machine?

Assembling your CNC machine can be a complex process, but with the right tools and a little patience, it is definitely achievable. It’s important to follow the instructions carefully and to double-check your work as you go.

Start by assembling the base of your machine, and then add the linear bearings and lead screws. Next, install the stepper motor, power supply, and controller board. Finally, add the spindle motor and any finishing touches. When you’re finished, test your machine to ensure that it is working properly.

How do I troubleshoot my CNC machine?

Even the most well-built CNC machines can experience issues from time to time. If you’re experiencing problems with your machine, the first step is to check all of your connections and wiring. Make sure that everything is properly connected and that there are no loose wires.

If you’re still experiencing issues, check your software settings to ensure that everything is configured correctly. You may also want to check the belts and pulleys to ensure that they are properly aligned and tightened.

What can I do with my CNC machine?

Once you have built your CNC machine, the possibilities are endless. You can use it to create everything from custom furniture to intricate jewelry. Some makers even use CNC machines to create their own circuit boards and 3D printers.

With a little imagination and creativity, you can use your CNC machine to bring your ideas to life. So get started today, and see where your CNC machine takes you!

In conclusion, building a CNC out of laser cut materials can be a challenging but rewarding experience. With the right tools and knowledge, anyone can create their own personalized CNC machine that meets their specific needs.

Not only is it cost-effective, but it also allows for complete customization and control over the machine’s capabilities. From cutting and engraving to 3D printing, a laser-cut CNC machine can do it all.

So, whether you’re a hobbyist or a professional, consider taking on the challenge of building your own CNC machine. With dedication and patience, you can create a powerful tool that will help you bring your ideas to life with precision and ease.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com