Table of Contents

- What Can a 3.5 Laser Do on a CNC Machine?

- 1. Cutting

- 2. Engraving

- 3. Marking

- 4. Benefits of using a 3.5 laser on a CNC machine

- 5. 3.5 laser vs. other lasers

- 6. Applications of a 3.5 laser on a CNC machine

- 7. Limitations of a 3.5 laser on a CNC machine

- 8. Maintenance of a 3.5 laser on a CNC machine

- 9. Cost of a 3.5 laser on a CNC machine

- 10. Conclusion

- Frequently Asked Questions

Laser technology has revolutionized many industries, including CNC machining. With the introduction of 3.5 laser technology, the capabilities of CNC machines have expanded even further. But what exactly can a 3.5 laser do on a CNC machine? Let’s dive in and explore the possibilities.

When it comes to CNC machining, precision is key. A 3.5 laser is capable of providing incredibly precise cuts and engravings, even on the smallest of surfaces. This technology allows for intricate designs and patterns to be created with ease, making it a game-changer for industries such as jewelry making and electronics manufacturing. But that’s not all it can do. Keep reading to discover the full potential of a 3.5 laser on a CNC machine.

What Can a 3.5 Laser Do on a CNC Machine?

Laser technology has revolutionized the manufacturing industry by enabling faster and more accurate cutting, engraving, and marking of various materials. A 3.5 laser is a type of laser used on CNC machines that has a wavelength of 3.5 microns. It is commonly used for cutting and marking materials such as plastics, paper, and thin metals. In this article, we will explore the capabilities and benefits of a 3.5 laser on a CNC machine.

1. Cutting

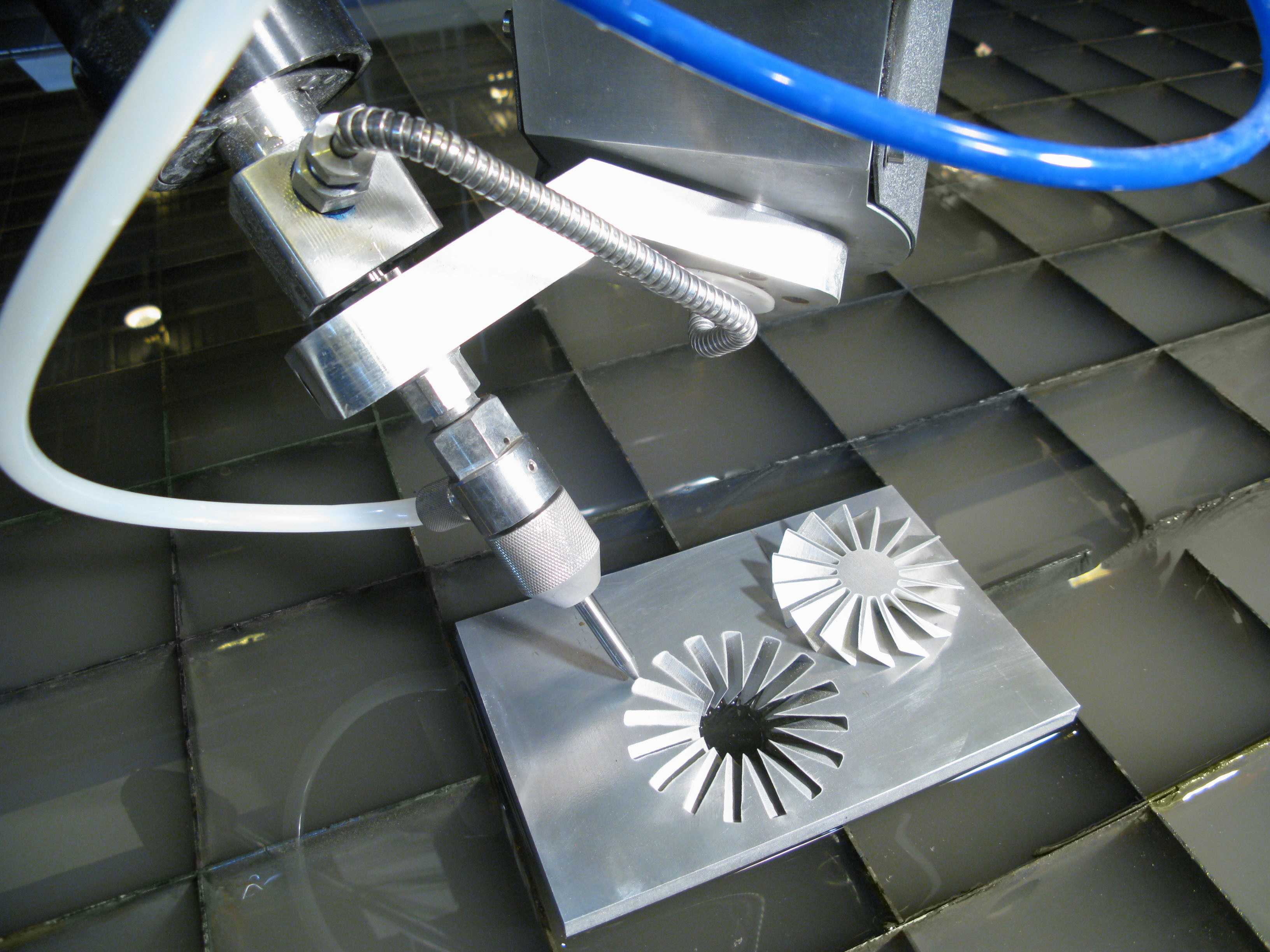

Cutting is one of the primary functions of a 3.5 laser on a CNC machine. This laser can cut through a variety of materials with precision and speed. With a 3.5 laser, you can cut materials such as acrylic, wood, and paper with ease. The laser beam is directed onto the material, and the intense heat generated by the laser vaporizes the material, leaving a clean and precise cut.

The benefits of using a 3.5 laser for cutting include its speed, accuracy, and the ability to cut intricate designs. It also produces clean cuts without the need for post-processing, which saves time and money.

2. Engraving

Another function of a 3.5 laser on a CNC machine is engraving. Engraving is the process of etching a design or text onto a material. The laser beam is directed onto the material, and the heat generated by the laser melts the material’s surface, creating a permanent mark.

A 3.5 laser is ideal for engraving because it can produce fine details and intricate designs with high precision. It can also engrave on a variety of materials such as wood, plastics, and metals.

3. Marking

Marking is the process of adding information or symbols onto a material. A 3.5 laser on a CNC machine can mark materials such as plastics, metals, and ceramics. The laser beam is directed onto the material, and the heat generated by the laser changes the material’s color, creating a permanent mark.

The benefits of using a 3.5 laser for marking include its speed, accuracy, and the ability to mark on a variety of materials. It can also produce high-quality marks that are permanent and resistant to wear.

4. Benefits of using a 3.5 laser on a CNC machine

Using a 3.5 laser on a CNC machine has several benefits. Firstly, it enables faster and more accurate cutting, engraving, and marking of various materials. Secondly, it eliminates the need for additional post-processing such as polishing, which saves time and money. Thirdly, it can produce high-quality cuts, engravings, and marks that are permanent and resistant to wear.

5. 3.5 laser vs. other lasers

Compared to other lasers, a 3.5 laser has a shorter wavelength, which makes it ideal for cutting and marking certain materials such as plastics and papers. Other types of lasers, such as CO2 lasers, have longer wavelengths and are more suitable for cutting thicker materials such as metals.

6. Applications of a 3.5 laser on a CNC machine

A 3.5 laser on a CNC machine has several applications in various industries. It can be used in the automotive industry for cutting and marking parts, in the medical industry for engraving medical devices, and in the electronics industry for cutting and marking circuit boards.

7. Limitations of a 3.5 laser on a CNC machine

While a 3.5 laser on a CNC machine has several benefits, it also has some limitations. For example, it is not suitable for cutting thick metals, and it may not be able to produce high-quality cuts on reflective materials. Additionally, it may require frequent maintenance to ensure optimal performance.

8. Maintenance of a 3.5 laser on a CNC machine

To ensure optimal performance and longevity, a 3.5 laser on a CNC machine requires regular maintenance. This includes cleaning the lens, checking the alignment, and replacing worn-out parts. Regular maintenance can help prevent breakdowns and ensure consistent and high-quality results.

9. Cost of a 3.5 laser on a CNC machine

The cost of a 3.5 laser on a CNC machine varies depending on the manufacturer, model, and features. Generally, a 3.5 laser is more expensive than other types of lasers, such as CO2 lasers. However, the benefits of using a 3.5 laser, such as its speed, accuracy, and versatility, may outweigh the cost for some businesses.

10. Conclusion

In conclusion, a 3.5 laser on a CNC machine is a powerful tool for cutting, engraving, and marking various materials. It offers several benefits, such as speed, accuracy, and versatility, and has several applications in various industries. While it has some limitations, regular maintenance can help ensure optimal performance and longevity. If you’re looking to invest in a laser for your CNC machine, a 3.5 laser may be a worthwhile investment.

Frequently Asked Questions

Here are some frequently asked questions about what a 3 5 laser can do on a CNC machine.

What is a 3 5 laser?

A 3 5 laser is a type of laser used in CNC machines that has a wavelength of 3.5 microns. This type of laser is ideal for cutting and engraving materials such as plastic, wood, and rubber. It is also commonly used in the electronics industry for marking and cutting silicon wafers.

The 3 5 laser is highly accurate and produces clean cuts with minimal heat affected zones. It is also capable of cutting through thicker materials than other types of lasers.

What materials can a 3 5 laser cut on a CNC machine?

A 3 5 laser can cut a wide range of materials on a CNC machine, including plastic, wood, rubber, and some metals. The laser is particularly effective at cutting thin materials, and can produce intricate designs with high precision.

When cutting certain materials, such as metals, it is important to use a protective gas to prevent oxidation and maintain the quality of the cut.

How does a 3 5 laser compare to other types of lasers on a CNC machine?

Compared to other types of lasers, such as CO2 and fiber lasers, a 3 5 laser has a shorter wavelength and is better suited for cutting and engraving non-metallic materials. It is also capable of cutting through thicker materials than other types of lasers.

However, CO2 and fiber lasers are better suited for cutting and engraving metals, and are generally more cost-effective than 3 5 lasers. The choice of laser depends on the specific application and material being worked on.

What are the benefits of using a 3 5 laser on a CNC machine?

Using a 3 5 laser on a CNC machine offers several benefits over other cutting methods. The laser is highly accurate and produces clean cuts with minimal heat affected zones. It is also capable of cutting through thicker materials than other types of lasers, making it ideal for certain applications.

In addition, the laser can produce intricate designs with high precision, making it ideal for applications such as engraving and marking. Overall, using a 3 5 laser on a CNC machine can save time and increase efficiency compared to other cutting methods.

What are some applications of using a 3 5 laser on a CNC machine?

There are a wide range of applications for using a 3 5 laser on a CNC machine. The laser is commonly used in the electronics industry for marking and cutting silicon wafers. It is also used in the automotive industry for cutting gaskets and other materials.

Other applications include cutting and engraving plastic, wood, and rubber for use in signage, packaging, and other industries. The high precision and accuracy of the laser make it ideal for producing intricate designs and shapes.

In conclusion, a 3.5 laser on a CNC machine can bring about remarkable results. With its high precision and accuracy, it can engrave and cut various materials with ease. This makes it an excellent option for those in the manufacturing and design industry who require intricate and detailed designs.

Moreover, the 3.5 laser can handle a wide range of materials, including wood, acrylic, and even some metals. This versatility allows manufacturers to create a vast array of products, from intricate jewelry to durable machine parts.

In summary, the addition of a 3.5 laser to a CNC machine can revolutionize the way manufacturers and designers approach their work. Its precision, accuracy, and versatility make it an invaluable tool that can bring about exceptional results.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com