Table of Contents

Laser CNC machines are a popular tool used in manufacturing and fabrication. But have you ever wondered how they work? These machines use a combination of computer numerical control (CNC) and laser technology to precisely cut and engrave a wide range of materials.

In this article, we will take a closer look at the inner workings of a laser CNC machine. From the basics of how a laser works to the intricate details of the CNC system, we will explore the fascinating world of laser cutting and engraving. So, buckle up and get ready to learn about one of the most revolutionary tools in modern manufacturing!

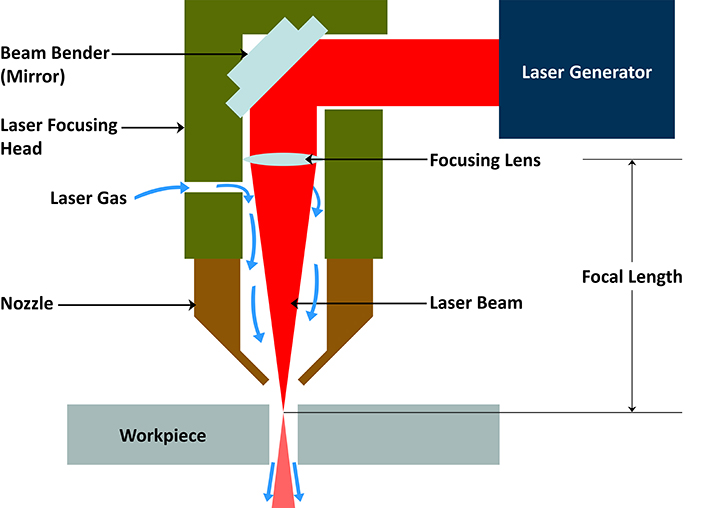

A laser CNC machine works by using a high-powered laser to cut, engrave or mark materials such as wood, plastic, and metal. The laser beam is guided by a computer-controlled system, which determines the path of the beam and the depth of the cut. The laser is generated by a tube filled with gas, such as CO2. When an electric current is passed through the gas, it produces a beam of light that is focused by a lens to create a high-intensity laser beam. The machine can be used for a wide range of applications, from precision cutting of intricate designs to engraving logos or text onto a surface.

How Does a Laser CNC Machine Work?

A laser CNC machine is a computer-controlled cutting device that utilizes a laser beam to cut, engrave, or etch materials such as wood, plastic, metal, and glass. The laser beam is emitted from a laser tube, which is powered by electricity and gas. The machine is operated by a computer program that controls the movement of the laser head, allowing for precise cuts and designs.

1. Laser Beam Generation

The laser beam is generated by a laser tube that is filled with a gas mixture such as carbon dioxide, nitrogen, and helium. When an electric current is passed through the gas mixture, it excites the gas molecules, causing them to emit photons. These photons are then amplified by mirrors inside the laser tube, creating a highly concentrated beam of light.

The laser beam is then directed through a lens, which focuses the beam into a small point. This highly focused beam is what allows the laser CNC machine to cut or engrave materials with precision.

2. Material Preparation

Before the laser CNC machine can begin cutting or engraving, the material must be prepared. This typically involves cleaning the surface of the material and placing it in the correct position on the machine’s cutting bed.

The machine’s cutting bed is typically made of a honeycomb or slatted material, which allows for the laser beam to pass through the material without damaging the machine’s components. The cutting bed also has a vacuum system that removes debris and smoke generated during the cutting process.

3. Machine Calibration

Once the material is prepared, the machine must be calibrated to ensure that the laser head is positioned correctly. This involves setting the correct focal length and adjusting the laser power to match the material being cut.

Calibration is critical to ensure that the machine produces accurate cuts and designs. A poorly calibrated machine can result in uneven cuts, burnt edges, or even damage to the machine itself.

4. Cutting and Engraving

With the material prepared and the machine calibrated, the laser CNC machine is ready to begin cutting or engraving. The computer program controls the movement of the laser head, directing it along the path of the desired design.

The laser beam cuts or engraves the material as it moves, creating precise and clean cuts. The speed and power of the laser can be adjusted to match the material being cut, allowing for a wide range of materials to be processed.

5. Material Removal

Once the cutting or engraving is complete, the material must be removed from the cutting bed. This is typically done by lifting the material off the bed or using a tool to remove any excess material.

The cutting bed is then cleaned to remove any debris or smoke generated during the cutting process. This ensures that the machine is ready for the next job.

6. Benefits of a Laser CNC Machine

One of the main benefits of a laser CNC machine is its precision. The highly focused laser beam allows for precise cuts and designs, making it an ideal tool for creating intricate patterns and shapes.

Another benefit is its versatility. A laser CNC machine can cut or engrave a wide range of materials, including wood, plastic, metal, and glass. This makes it a valuable tool for a variety of industries, including manufacturing, woodworking, and jewelry making.

7. Laser CNC Machine Vs. Traditional Cutting Methods

Compared to traditional cutting methods such as sawing or milling, a laser CNC machine offers several advantages. First, it is faster and more efficient, allowing for larger volumes of material to be processed in a shorter amount of time.

Second, it produces cleaner cuts with less waste. Traditional cutting methods often result in jagged edges or excess material, which must be removed or sanded down. A laser CNC machine produces clean and precise cuts, reducing the need for additional finishing work.

8. Applications of a Laser CNC Machine

A laser CNC machine has a wide range of applications, including:

– Cutting and engraving wood for furniture, signs, and decorative items

– Engraving glass and metal for jewelry and awards

– Cutting and engraving plastic for promotional items and signage

– Cutting and engraving fabric and leather for clothing and accessories

– Cutting and engraving paper and cardboard for packaging and printing

9. Maintenance and Safety

To ensure the safe and efficient operation of a laser CNC machine, regular maintenance is required. This includes cleaning the machine’s components, inspecting the laser tube and mirrors, and replacing any worn or damaged parts.

It is also important to follow proper safety procedures when using a laser CNC machine. This includes wearing appropriate personal protective equipment, such as safety glasses and gloves, and ensuring that the machine is properly ventilated to prevent the buildup of smoke and fumes.

10. Conclusion

A laser CNC machine is a powerful tool that offers precision, versatility, and efficiency. Whether you are a small business owner, a hobbyist, or a professional craftsman, a laser CNC machine can help you create beautiful and intricate designs with ease. By understanding how a laser CNC machine works and following proper safety and maintenance procedures, you can take full advantage of this amazing technology.

Frequently Asked Questions

In this section, we will answer some of the commonly asked questions about laser CNC machines and their working mechanism. Read on to find out more.

What is a Laser CNC machine?

A Laser CNC machine is a computer-controlled machine that uses a laser beam to cut, engrave, or etch materials such as wood, plastic, and metal. These machines are widely used in manufacturing, prototyping, and hobbyist projects.

The machine consists of a laser source, a controller, and a bed where the material to be cut or engraved is placed. The laser beam is directed by mirrors or lenses to the material, which is then cut or engraved according to the programmed design.

How does a Laser CNC machine work?

The Laser CNC machine works by using a high-powered laser beam to cut or engrave the material. The laser beam is directed by mirrors or lenses to the material, which is then cut or engraved according to the programmed design.

The controller of the machine determines the path of the laser beam and the intensity of the laser. The intensity of the laser is controlled by adjusting the power and the speed of the laser beam. The laser beam cuts through the material by vaporizing it, leaving behind a clean cut or engraving.

What materials can be cut or engraved using a Laser CNC machine?

A Laser CNC machine can cut or engrave a variety of materials such as wood, plastic, metal, leather, and acrylic. The cutting and engraving capabilities of the machine depend on the power of the laser and the type of material being used.

For example, a low-powered laser may be able to cut through thin materials such as paper or cardboard, while a high-powered laser can cut through thick materials such as metal or wood.

What are the advantages of using a Laser CNC machine?

The Laser CNC machine offers several advantages over traditional cutting and engraving methods. Firstly, it offers a high level of precision and accuracy, allowing for intricate designs and shapes to be cut or engraved with ease.

Additionally, the machine offers a high level of repeatability, meaning that the same design can be replicated multiple times with the same level of accuracy. Finally, the machine is fast and efficient, allowing for quick turnaround times and increased productivity.

What are the limitations of a Laser CNC machine?

While Laser CNC machines offer several advantages, they also have some limitations. Firstly, they are limited in terms of the size of the material that can be cut or engraved. The size of the bed limits the size of the material that can be processed.

Additionally, the machine can only cut or engrave certain materials. For example, some metals may not be suitable for cutting or engraving due to their chemical composition. Finally, the machine requires regular maintenance and calibration to ensure optimal performance.

In conclusion, a laser CNC machine is a sophisticated piece of equipment that utilizes advanced laser technology to create precise cuts and engravings on various materials. The machine is operated through a computer program that controls the laser’s movements, speed, and intensity. This allows for highly accurate results and intricate designs that would be impossible to achieve by hand.

With its ability to cut through a wide range of materials, including metal, wood, and plastic, a laser CNC machine is a valuable tool for many industries. Whether you’re a hobbyist or a professional, this machine can help you bring your ideas to life with speed and precision.

Investing in a laser CNC machine can be a game-changer for businesses looking to streamline their manufacturing processes and increase output. With its versatility, accuracy, and speed, this machine is sure to become an essential part of any production line.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com