Table of Contents

Hydraulics are an essential part of modern machinery, and they play a vital role in CNC machines. These machines are used to manufacture a wide range of products, from automotive parts to medical devices. Understanding how hydraulics work on a CNC machine is essential for anyone interested in manufacturing or engineering.

Hydraulics use fluids to transfer energy and power, and they are ideal for heavy-duty applications. In a CNC machine, hydraulics are used to power the cutting tools, control the movement of the axes, and clamp and unclamp the workpiece. By understanding the basics of hydraulics, you can gain a deeper insight into how CNC machines work, and how they are used in modern manufacturing.

**H2: How Hydraulics Work on a CNC Machine?**

Hydraulics play a crucial role in the operation of CNC machines, which are used in a variety of industries ranging from manufacturing to aerospace. Understanding how hydraulics work on a CNC machine is critical to ensure proper operation and maintenance of these machines.

**H3: What is a CNC Machine?**

A CNC (Computer Numerical Control) machine is a manufacturing tool that is programmed to perform specific tasks automatically. These machines use a combination of computer software and mechanical components to control the movement of cutting tools, allowing for precise and accurate cuts to be made.

**H3: What are Hydraulics?**

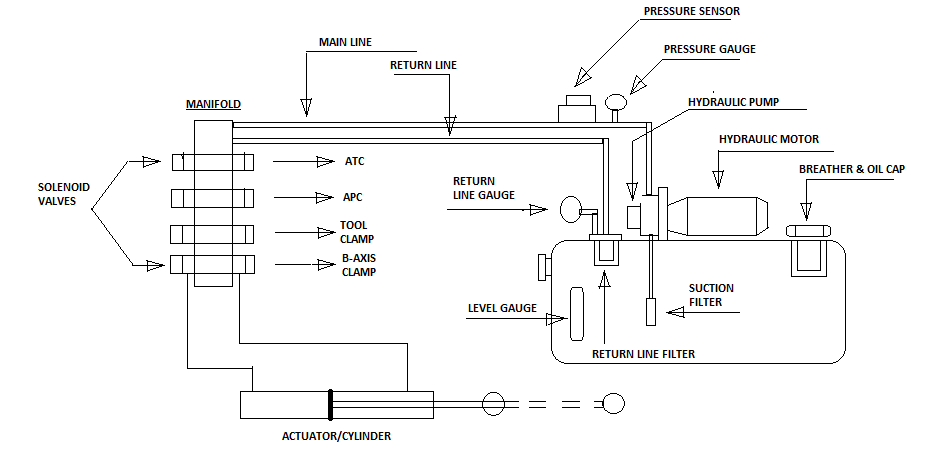

Hydraulics is a system that uses liquids to generate power and control movement. A hydraulic system typically consists of a pump, a reservoir, and various valves and actuators that work together to control the flow of fluid and convert it into mechanical energy.

**H3: How Do Hydraulics Work on a CNC Machine?**

Hydraulics on a CNC machine are used to control the movement of the cutting tools and workpiece. The hydraulic system is typically used to power the machine’s spindle, which rotates the cutting tool, as well as the machine’s axes, which control the movement of the cutting tool and workpiece.

The hydraulic system is controlled by a series of valves and actuators that regulate the flow of fluid to the various components of the machine. The hydraulic pump is responsible for generating the necessary pressure to drive the system and provide the required power to move the cutting tool and workpiece.

**H3: Benefits of Using Hydraulics on a CNC Machine**

One of the main benefits of using hydraulics on a CNC machine is the ability to generate high levels of power and torque. Hydraulics can produce much greater force than other types of systems, which makes them ideal for heavy-duty applications such as machining.

Hydraulics are also very reliable and durable, making them a popular choice for use in CNC machines. They require minimal maintenance and can last for many years with proper care and upkeep.

**H3: Hydraulics vs. Other Types of Systems**

Hydraulics are often compared to other types of systems, such as pneumatics and electric systems. While each of these systems has its own advantages and disadvantages, hydraulics are generally considered to be more powerful and reliable than other types of systems.

Pneumatic systems, for example, use compressed air to generate power, which can limit the amount of force that can be generated. Electric systems, on the other hand, can be more complex and require more maintenance than hydraulic systems.

**H3: Maintaining Hydraulics on a CNC Machine**

Proper maintenance of the hydraulic system on a CNC machine is critical to ensure reliable operation and prevent downtime. Regular inspections should be performed to check for leaks, damage, and wear on the system’s components.

The hydraulic fluid should be checked and replaced periodically, and the system should be flushed and cleaned to remove any contaminants that may have accumulated. It is also important to follow the manufacturer’s recommended maintenance schedule and procedures to ensure proper operation and avoid any potential issues.

**H3: Conclusion**

Hydraulics play a critical role in the operation of CNC machines, providing the power and control necessary to produce precise and accurate cuts. Understanding how hydraulics work on a CNC machine is essential for anyone working with these machines, and proper maintenance is crucial to ensure reliable operation and prevent downtime. By following the manufacturer’s recommended maintenance procedures and taking care of the hydraulic system, CNC machine operators can enjoy reliable operation and long service life from their machines.

Frequently Asked Questions

Hydraulics is an essential part of a CNC machine. It is a type of fluid power system that uses liquid to power various components of the machine. Here are some frequently asked questions about how hydraulics work on a CNC machine.

What is a hydraulic system in a CNC machine?

A hydraulic system is a type of fluid power system that uses liquid to power various components of the CNC machine. The system works by converting mechanical energy into hydraulic energy, which is then used to power various parts of the machine. The hydraulic system consists of various components, such as a hydraulic pump, motor, cylinder, and valves. These components work together to ensure that the CNC machine operates smoothly and efficiently.

The hydraulic system is responsible for controlling the movement of the machine’s axes, providing lubrication to the moving parts, and ensuring the accuracy of the machining process. This system is critical to the performance and longevity of the CNC machine.

How does a hydraulic pump work in a CNC machine?

The hydraulic pump is the heart of the hydraulic system in a CNC machine. It is responsible for converting mechanical energy into hydraulic energy, which is then used to power the various components of the machine. The pump works by drawing hydraulic fluid from the reservoir and pumping it into the hydraulic system at high pressure. This high-pressure fluid is then used to power the various components of the machine, such as the cylinders, motors, and valves.

There are two types of hydraulic pumps commonly used in CNC machines: the gear pump and the vane pump. The gear pump is a positive displacement pump that uses a set of interlocking gears to pump the fluid. The vane pump, on the other hand, uses a set of vanes that rotate inside a circular chamber to pump the fluid. Both types of pumps are reliable and efficient, but the vane pump is more commonly used in CNC machines due to its lower noise level and higher efficiency.

What is a hydraulic cylinder in a CNC machine?

A hydraulic cylinder is a critical component of the hydraulic system in a CNC machine. It is responsible for converting hydraulic energy into mechanical energy, which is then used to move the various components of the machine. The cylinder consists of a piston, a cylinder barrel, and a hydraulic connection. When hydraulic fluid is pumped into the cylinder, it pushes the piston, which in turn moves the component that is attached to the piston.

There are two types of hydraulic cylinders commonly used in CNC machines: the single-acting cylinder and the double-acting cylinder. The single-acting cylinder uses hydraulic pressure to move the piston in one direction, while a spring or other external force is used to return the piston to its original position. The double-acting cylinder, on the other hand, uses hydraulic pressure to move the piston in both directions, allowing for more precise control over the movement of the machine’s components.

What is a hydraulic valve in a CNC machine?

A hydraulic valve is a critical component of the hydraulic system in a CNC machine. It is responsible for controlling the flow of hydraulic fluid to the various components of the machine. The valve consists of a spool, which is moved by hydraulic pressure, and a series of ports that control the flow of fluid to the different parts of the machine.

There are several types of hydraulic valves commonly used in CNC machines, including the directional control valve, the pressure control valve, and the flow control valve. The directional control valve is used to control the direction of the fluid flow, while the pressure control valve is used to control the pressure of the fluid. The flow control valve is used to control the rate of fluid flow to the various components of the machine.

What are the benefits of using a hydraulic system in a CNC machine?

There are several benefits to using a hydraulic system in a CNC machine. First, hydraulic systems are highly efficient, providing a high level of power output with minimal energy input. Second, hydraulic systems are highly reliable, with a long service life and minimal maintenance requirements. Third, hydraulic systems are highly precise, allowing for precise control over the movement of the machine’s components. Finally, hydraulic systems are highly flexible, allowing for the use of a wide range of components and configurations to meet the specific needs of the CNC machine.

Overall, the use of a hydraulic system is essential to the performance and longevity of a CNC machine, ensuring that it operates smoothly and efficiently to produce high-quality machined parts.

In conclusion, hydraulics play a critical role in the operation of a CNC machine. They are responsible for powering the cutting tools and other components, ensuring that the machine operates smoothly and efficiently. By converting pressure into force, hydraulics enable CNC machines to perform complex tasks with precision and accuracy.

While the principles of hydraulics may seem complex, they are actually quite simple. By understanding the basics of how hydraulics work, you can gain a greater appreciation for the inner workings of a CNC machine. Whether you’re a machinist or simply interested in the technology behind these powerful machines, knowledge of hydraulics is essential.

Overall, hydraulics are an essential component of any CNC machine. They allow for precise control and consistent performance, making them an indispensable tool in industries ranging from manufacturing to aerospace. With their ability to convert pressure into force, hydraulics are the driving force behind the success of CNC machines, enabling them to perform complex tasks with ease and accuracy.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com