Table of Contents

Are you considering purchasing a CNC machine, but not sure if it’s worth the investment? With the rise of automation and technology in manufacturing, it’s a question that many business owners and hobbyists are asking themselves. In this article, we’ll explore the benefits and drawbacks of owning a CNC machine, and help you make an informed decision on whether it’s the right choice for you. Let’s dive in!

Should I Buy a CNC Machine?

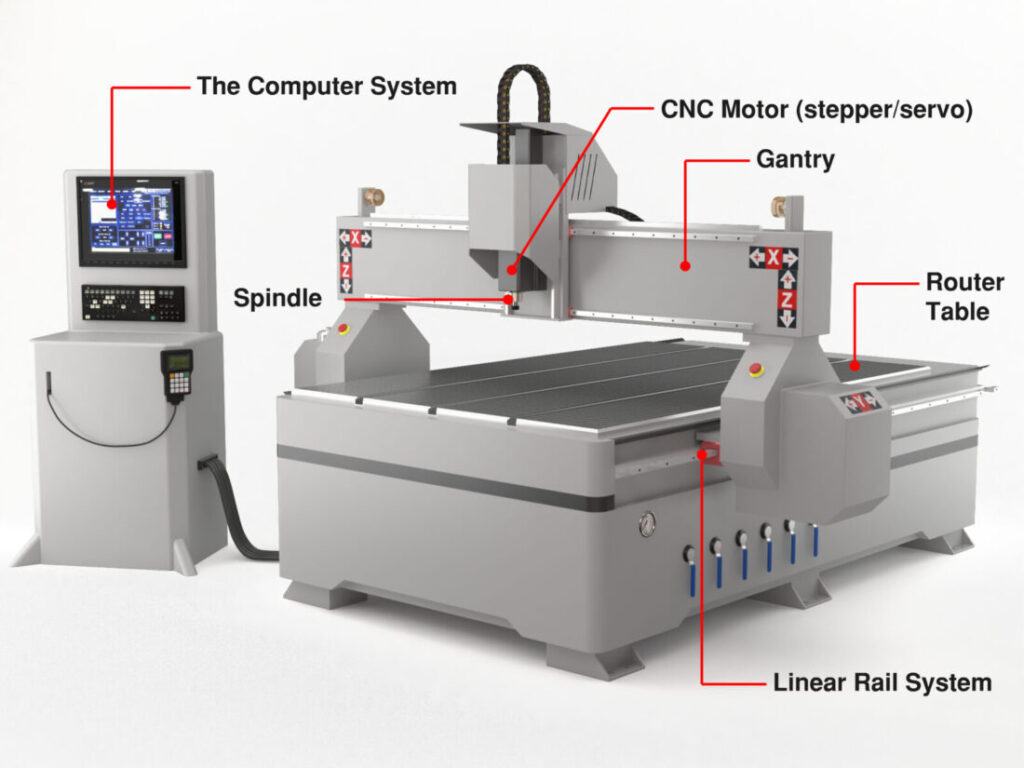

If you are in the manufacturing industry, you might be wondering if investing in a CNC machine is worth it. Computer Numerical Control (CNC) machines are automated tools that can perform precise cuts and shapes on a variety of materials. In this article, we will explore the benefits of owning a CNC machine and help you determine if it is the right investment for your business.

Increased Precision

One of the main advantages of a CNC machine is its ability to achieve high levels of precision. As the machine is controlled by a computer, it can make accurate cuts and shapes repeatedly without any variation. This level of precision is essential for manufacturing products with intricate designs, such as aerospace components or medical implants.

CNC machines also eliminate the possibility of human error. When cutting or shaping materials by hand, it is common for mistakes to occur, which can be costly and time-consuming. With a CNC machine, you can ensure that every product is manufactured to the exact specifications, reducing the risk of errors.

| Hand Cutting | CNC Machine |

|---|---|

| Higher risk of human error | Consistent accuracy |

| Slower production times | Efficient production |

| Less precise cuts and shapes | High precision |

Increased Efficiency

CNC machines are also beneficial for increasing productivity and efficiency. As the machine can operate continuously without the need for breaks or rest, it can produce higher volumes of products in a shorter amount of time. This is particularly useful for large-scale manufacturing operations where time is of the essence.

CNC machines also have the capability to perform multiple operations on a single piece of material, such as drilling, milling, and cutting. This reduces the need for multiple machines and manual labor, resulting in a more streamlined manufacturing process.

- Increased productivity

- Faster production times

- Ability to perform multiple operations on a single machine

Cost-Effective

Although CNC machines can be expensive, they are a cost-effective investment in the long run. As the machine can operate continuously and produce higher volumes of products, it can ultimately save you money on labor costs. Additionally, the high level of precision means that there is less waste material, resulting in further cost savings.

CNC machines also have the capability to produce complex designs that may be difficult or impossible to manufacture by hand. This allows you to expand your product line and enter new markets, increasing your revenue potential and overall profitability.

- High precision means less waste material

- Operates continuously, reducing labor costs

- Ability to produce complex designs, expanding your product line

Should You Buy a CNC Machine?

Investing in a CNC machine requires careful consideration and analysis of your business needs. If you are looking to increase precision, efficiency, and profitability, a CNC machine may be the right investment for you. However, if you have lower production needs or limited resources, it may not be the best choice.

It is essential to research and compare different CNC machines and their capabilities before making a purchase. Additionally, consider the ongoing maintenance costs and training required for your employees to operate the machine effectively.

In conclusion, a CNC machine can be a valuable asset to your manufacturing business, offering increased precision, efficiency, and cost savings. However, it is important to consider your specific needs and resources before making a significant investment.

Frequently Asked Questions

Are you considering investing in a CNC machine? Here are some frequently asked questions to help you decide whether it’s the right choice for your business.

What is a CNC machine?

A CNC (Computer Numerical Control) machine is a computer-controlled tool used for cutting and shaping materials such as wood, metal, and plastic. It is a highly accurate and efficient tool that can produce complex shapes with great precision.

These machines are often used in manufacturing, woodworking, and engineering industries to create parts, prototypes, and products. They can be programmed to produce identical parts, reducing the risk of human error and increasing productivity.

What are the benefits of owning a CNC machine?

Owning a CNC machine can bring several benefits to your business. Firstly, it can increase your productivity and efficiency, as it can produce parts and products faster and with greater accuracy than traditional methods. This can result in cost savings and increased profits.

Secondly, owning a CNC machine can give you greater control over your production process. You can create custom parts and products to meet specific customer requirements, giving you a competitive advantage in your industry. Finally, owning a CNC machine can help you stay ahead of the curve in terms of technology, which can be a valuable asset in today’s fast-paced business world.

What factors should I consider before buying a CNC machine?

Before investing in a CNC machine, it’s important to consider several factors. Firstly, you need to assess your business needs and determine whether a CNC machine is the right choice for your industry. You should also consider the size and type of machine that would be most suitable for your business.

Other factors to consider include the cost of the machine, the availability of skilled operators, and the ongoing maintenance and support required. It’s also important to consider the potential return on investment, and whether the benefits of owning a CNC machine outweigh the initial costs.

How much does a CNC machine cost?

The cost of a CNC machine can vary widely depending on the type and size of machine you require, as well as the features and capabilities you need. Entry-level machines can cost anywhere from $5,000 to $10,000, while high-end, industrial-grade machines can cost up to $500,000 or more.

It’s important to remember that the initial cost of the machine is just one factor to consider. Ongoing maintenance, repairs, and upgrades will also add to the overall cost of owning a CNC machine. However, the potential benefits in terms of increased productivity and profits may outweigh the initial investment.

Do I need specialized training to operate a CNC machine?

Operating a CNC machine does require specialized training, as it involves programming and operating complex computer systems. However, many manufacturers offer training and support for their machines, and there are also training courses and certifications available for operators.

If you’re considering investing in a CNC machine, it’s important to assess the availability of skilled operators in your area, and whether you have the resources to provide ongoing training and support for your employees.

In conclusion, whether or not you should buy a CNC machine depends on your specific needs and goals. If you are looking to increase production efficiency, reduce labor costs, and improve accuracy, then investing in a CNC machine may be a wise decision. However, if your production needs are small or you are not yet ready to make a significant financial investment, it may be better to hold off on purchasing a CNC machine for the time being.

Overall, it is important to consider all factors before making a decision. Take the time to research different CNC machines, assess your production needs and capabilities, and weigh the costs and benefits. By doing so, you can make an informed decision that will benefit your business in the long run.

Ultimately, a CNC machine can be a valuable asset for businesses of all sizes and industries. With its ability to increase efficiency and accuracy, it can help take your production capabilities to the next level. So, if you are ready to take your business to new heights, a CNC machine may be the perfect investment for you.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com